Innovation Accelerates in Injection Molds for Wine Bottle Plastic Caps as Global Beverage Packaging Upgrades

Injection molds for wine bottle plastic caps are advancing with precision, sustainability, and customization as global wineries seek better sealing and efficient production.

2025-12-04

The global wine and beverage industry is undergoing rapid transformation, and one of the most significant changes is happening quietly within the packaging sector. Among these developments, injection molds for wine bottle plastic caps are taking center stage. With rising demand for premium, durable, and environmentally friendly packaging, mold manufacturers are pushing the limits of precision engineering, production efficiency, and material innovation. As wineries seek enhanced sealing performance and brand customization, the market for high-quality injection molds continues to expand globally.

In recent years, the shift from traditional metal caps to plastic caps has accelerated, driven by cost efficiency, safety concerns, and improvements in food-grade plastics. Plastic wine bottle caps now offer excellent sealing ability, tamper-evident design, long-term durability, and broad customization options. To match this evolution, mold makers are adopting advanced steel materials, improved gating systems, and innovative cooling layouts to ensure cap uniformity, stability, and consistent mass production.

Industry experts note that modern injection molds for wine bottle plastic caps rely heavily on precision machining technologies such as CNC high-speed milling, EDM micro-spark processing, and multi-axis machining centers. These advanced manufacturing methods allow mold components to achieve accuracy within microns, directly improving cap thread accuracy—one of the most critical aspects influencing sealing performance. With proper thread formation, the cap can maintain air-tightness, prevent leakage, and preserve the original flavor and aroma of wine.

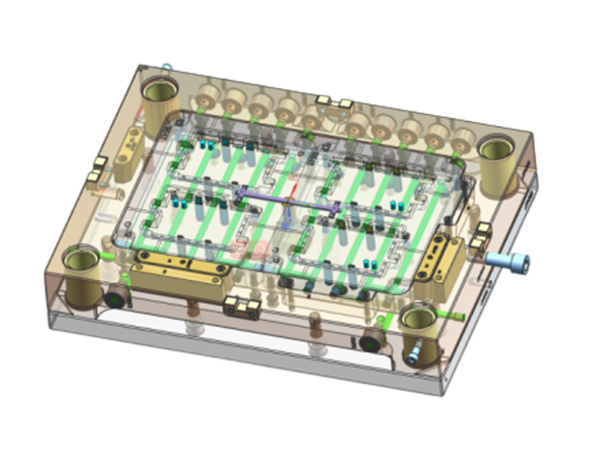

At the same time, mold structure design is rapidly evolving. Hot runner systems are now widely integrated into wine bottle cap molds to reduce material waste, eliminate runner scrap, and stabilize injection temperature. These improvements significantly boost production efficiency while lowering overall manufacturing costs for wineries and cap manufacturers. Many mold factories also provide multi-cavity mold options—ranging from 8-cavity to 64-cavity layouts—allowing mass production at remarkable speeds to meet growing market orders.

Sustainability is another major driving force in the market. As environmental policies tighten worldwide, wine producers are seeking eco-friendly caps made from recyclable materials. To support this trend, mold engineers are developing molds compatible with biodegradable plastics, lightweight cap designs, and energy-efficient mold cooling systems. These innovations reduce energy consumption, shorten cycle time, and minimize waste, helping manufacturers achieve both environmental and economic benefits.

Customization has also become a powerful competitive factor. Wineries increasingly demand caps with personalized logos, embossing, unique textures, and diverse color options to strengthen brand identity. In response, mold makers offer advanced engraving, laser etching, and surface treatment techniques to replicate even the finest design details. With these capabilities, customized caps can enhance the consumer's perception of brand quality and product authenticity.

The global supply chain also plays a critical role. China has emerged as one of the largest manufacturers of injection molds for wine bottle plastic caps, thanks to its mature mold industry, competitive pricing, and fast delivery capabilities. Chinese mold companies export products to Europe, the United States, South America, and Southeast Asia, serving both large wineries and small-scale beverage producers. Many factories now provide complete cap production solutions, including mold design, injection machines, cap testing equipment, and technical support.

Looking forward, industry analysts predict that the demand for high-precision, high-efficiency, and eco-friendly injection molds for wine bottle plastic caps will continue rising as the global wine market grows and packaging standards advance. Technologies such as smart molding, AI-based quality inspection, and digital twins are expected to further revolutionize mold manufacturing. With ongoing innovation and international collaboration, the injection mold sector is poised to play a key role in shaping the next era of wine packaging.

Related news