Exploring the Materials Used in Injection Molding for Auto Dashboards

Exploring the Materials Used in Injection Molding for Auto Dashboards In the automotive industry, **auto dashboards** serve as more than just a functional component; they are integral to the overall aesthetic and user experience of a vehicle. The production of these dashboards often involves **injection molding**, a highly efficient manufacturing process that utilizes various materials, each chose

2026-02-19

Exploring the Materials Used in Injection Molding for Auto Dashboards

In the automotive industry, **auto dashboards** serve as more than just a functional component; they are integral to the overall aesthetic and user experience of a vehicle. The production of these dashboards often involves **injection molding**, a highly efficient manufacturing process that utilizes various materials, each chosen for their specific properties. In this article, we will explore the materials commonly used in injection molding for auto dashboards, the benefits of these materials, and the future trends in dashboard manufacturing.

Table of Contents

- 1. Introduction to Injection Molding

- 2. Understanding the Materials Used

- 3. Key Material Properties

- 4. The Injection Molding Process

- 5. Benefits of Using Injection Molding for Dashboards

- 6. Environmental Considerations

- 7. Future Trends in Dashboard Materials

- 8. FAQs

- 9. Conclusion

1. Introduction to Injection Molding

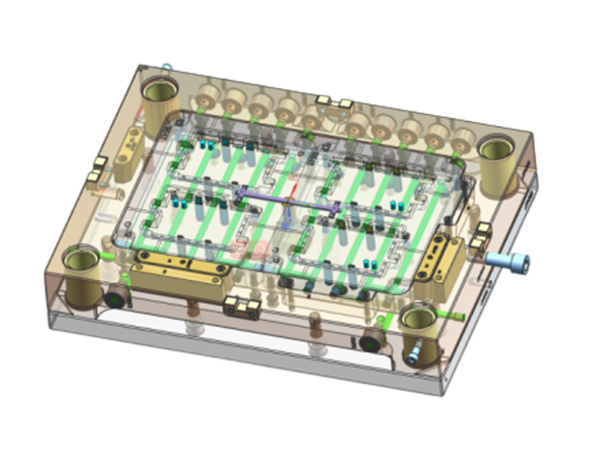

**Injection molding** is a widely used manufacturing technique in the automotive industry, particularly for producing complex shapes and components with precision. The process involves injecting molten material into a mold, where it cools and solidifies into the desired form. This method is favored for its speed, cost-effectiveness, and ability to produce large volumes of parts with consistent quality.

2. Understanding the Materials Used

The choice of materials used in injection molding for auto dashboards is crucial, as it directly affects the performance, durability, and appearance of the final product. Here, we will discuss the most common types of materials used in this process.

2.1 Thermoplastics

Thermoplastics are one of the most commonly used materials in injection molding for dashboards due to their excellent moldability and physical properties. These materials can be reheated and reshaped, making them highly versatile. Some popular thermoplastics used for auto dashboards include:

- Polypropylene (PP): Known for its lightweight nature and resistance to chemicals, PP is often used in dashboards to enhance fuel efficiency.

- Acrylonitrile Butadiene Styrene (ABS): ABS offers high strength and impact resistance, making it ideal for parts that require durability.

- Polycarbonate (PC): With its remarkable optical clarity and high heat resistance, PC is used for components that require transparency or elevated temperature stability.

2.2 Thermosetting Plastics

Unlike thermoplastics, thermosetting plastics cannot be remolded once they are cured. They are known for their rigidity and thermal stability, which are essential attributes for dashboard applications. Key types of thermosetting plastics include:

- Polyester Resins: These are often used in combination with fiberglass to create lightweight yet strong dashboard components.

- Epoxy Resins: Renowned for their excellent adhesive properties and thermal stability, epoxy resins are used in applications requiring high performance.

2.3 Composites

Composite materials combine two or more different materials to create a product that possesses the best qualities of each. In dashboard applications, composites are often used to reduce weight while maintaining strength. Common composites include:

- Carbon Fiber Composites: These materials are incredibly lightweight and provide high tensile strength, making them suitable for high-performance vehicles.

- Glass Fiber Reinforced Plastics (GFRP): GFRP offers enhanced strength and stiffness, making it ideal for dashboards that require robustness.

3. Key Material Properties

When selecting materials for injection molding, several properties must be considered to ensure the performance and durability of the dashboard. Key material properties include:

- Impact Resistance: Dashboards need to withstand impacts during accidents without shattering.

- Heat Resistance: The materials must not deform or degrade under high temperatures, especially from the vehicle's engine and sunlight.

- Aesthetics: The choice of material affects the visual and tactile quality of the dashboard, which is critical for user experience.

- Chemical Resistance: Dashboards are exposed to various chemicals, including oils and cleaning agents; materials must resist degradation from these substances.

4. The Injection Molding Process

The injection molding process involves several key steps:

- Material Preparation: The chosen plastic materials are prepared and dried to remove moisture.

- Injection: The plastic is heated until it becomes molten and then injected into a mold at high pressure.

- Cooling: The mold is cooled, allowing the material to solidify into the desired shape.

- Demolding: Once cooled, the mold opens, and the finished part is removed.

- Finishing: Additional processes, such as painting or coating, may be applied to enhance the dashboard's appearance.

5. Benefits of Using Injection Molding for Dashboards

Injection molding offers numerous benefits for producing auto dashboards:

- High Production Speed: The process allows for rapid production, making it suitable for large-scale manufacturing.

- Cost Efficiency: Once the mold is made, the cost per unit decreases significantly with increased production volumes.

- Design Flexibility: Complex designs can be achieved easily, accommodating various dashboard styles.

- Material Utilization: Minimal waste is generated during the process, contributing to more sustainable manufacturing.

6. Environmental Considerations

With the growing emphasis on sustainability, the materials used in injection molding are increasingly being scrutinized for their environmental impact. Some considerations include:

- Recyclability: Many thermoplastics can be recycled, reducing waste and conserving resources.

- Biodegradable Options: Some manufacturers are exploring biodegradable plastics derived from natural materials, aiming to lessen the environmental footprint.

- Energy Consumption: Optimizing the injection molding process can lead to reduced energy use and lower emissions.

7. Future Trends in Dashboard Materials

As the automotive industry evolves, so do the materials used for dashboards. Some future trends include:

- Smart Materials: The integration of sensors and displays into dashboards may lead to the use of materials that can adapt to various conditions.

- 3D Printing: This technology allows for rapid prototyping and customization of dashboard components, potentially changing traditional manufacturing methods.

- Sustainable Practices: As consumer demand for eco-friendly products grows, manufacturers are likely to focus on developing more sustainable materials and practices.

8. FAQs

What types of materials are best for auto dashboards?

Thermoplastics like PP and ABS are commonly used due to their durability and flexibility. Thermosetting plastics and composites are also popular for their strength and thermal resistance.

How does injection molding impact the cost of auto dashboards?

Injection molding is cost-effective for mass production. While the initial mold cost is high, the cost per unit decreases significantly with higher volumes.

Are the materials used in dashboards recyclable?

Many thermoplastics are recyclable, which reduces waste and environmental impact. However, thermosetting plastics generally are not recyclable.

What is the role of aesthetics in dashboard material selection?

Aesthetics play a crucial role in enhancing the user experience. The materials chosen must not only be functional but also visually appealing.

How can manufacturers ensure the environmental sustainability of dashboard production?

Manufacturers can opt for recyclable materials, minimize energy consumption during production, and explore biodegradable options.

9. Conclusion

Understanding the materials used in injection molding for auto dashboards is essential for anyone involved in the automotive industry. From thermoplastics to composites, each material offers unique properties that cater to the demands of modern vehicles. As technology and consumer preferences evolve, so too will the materials and processes used in dashboard production. By staying informed about these developments, industry professionals can ensure that they remain at the forefront of automotive manufacturing.

Related news