Understanding Injection Molds for Drain Trays: A Comprehensive Guide

Injection molding has become an essential technique in the manufacturing of various plastic components, and drain trays are no exception. These trays, often utilized in kitchens, gardens, and industrial settings, require precise design and production techniques to ensure efficiency and durability. Understanding the fundamentals of injection molds for drain trays can significantly enhance your prod

2026-02-07

Injection molding has become an essential technique in the manufacturing of various plastic components, and drain trays are no exception. These trays, often utilized in kitchens, gardens, and industrial settings, require precise design and production techniques to ensure efficiency and durability. Understanding the fundamentals of injection molds for drain trays can significantly enhance your production process and product quality.

The first step in creating an injection mold for a drain tray is the design phase. It is crucial to consider the functionality of the tray, including the drainage system, shape, and dimensions. Advanced CAD software can be employed to create detailed designs that optimize flow and minimize material waste. Additionally, considerations such as draft angles and mold release features should be integrated into the design to facilitate easy ejection of the final product.

Material selection is another critical factor. Drain trays are often exposed to various environmental conditions, so durability is key. Commonly used materials include polypropylene, polyethylene, and polystyrene, each with its own set of properties that can affect the tray's performance. For instance, polypropylene is known for its excellent chemical resistance and durability, making it a popular choice for drain trays in commercial settings.

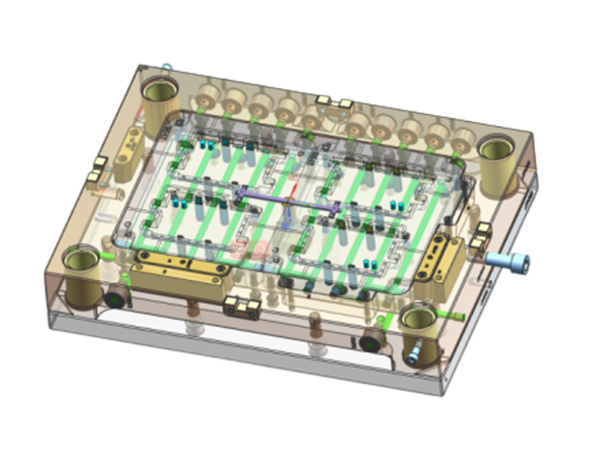

Once the design and materials are finalized, the manufacturing process can begin. The production of injection molds typically involves machining processes where steel or aluminum is shaped into the desired form. High-precision CNC machines are often used to achieve the intricate details required for the mold. The final mold will go through rigorous testing to ensure it meets the design specifications and can produce consistent, high-quality drain trays.

After the mold has been created, the injection molding process can start. Plastic pellets are heated until they reach a molten state and then injected into the mold under high pressure. This method ensures that the material fills the mold cavities completely, resulting in a uniform product. The cooling phase is equally crucial, as it determines the final properties of the drain tray, including strength and appearance.

In conclusion, creating an injection mold for drain trays involves a meticulous process that encompasses design, material selection, manufacturing, and production. By focusing on these aspects, professionals in the manufacturing and processing industry can ensure that their drain trays not only meet functional requirements but also excel in quality and durability. Understanding these factors will ultimately lead to more efficient production and satisfied end-users.

The first step in creating an injection mold for a drain tray is the design phase. It is crucial to consider the functionality of the tray, including the drainage system, shape, and dimensions. Advanced CAD software can be employed to create detailed designs that optimize flow and minimize material waste. Additionally, considerations such as draft angles and mold release features should be integrated into the design to facilitate easy ejection of the final product.

Material selection is another critical factor. Drain trays are often exposed to various environmental conditions, so durability is key. Commonly used materials include polypropylene, polyethylene, and polystyrene, each with its own set of properties that can affect the tray's performance. For instance, polypropylene is known for its excellent chemical resistance and durability, making it a popular choice for drain trays in commercial settings.

Once the design and materials are finalized, the manufacturing process can begin. The production of injection molds typically involves machining processes where steel or aluminum is shaped into the desired form. High-precision CNC machines are often used to achieve the intricate details required for the mold. The final mold will go through rigorous testing to ensure it meets the design specifications and can produce consistent, high-quality drain trays.

After the mold has been created, the injection molding process can start. Plastic pellets are heated until they reach a molten state and then injected into the mold under high pressure. This method ensures that the material fills the mold cavities completely, resulting in a uniform product. The cooling phase is equally crucial, as it determines the final properties of the drain tray, including strength and appearance.

In conclusion, creating an injection mold for drain trays involves a meticulous process that encompasses design, material selection, manufacturing, and production. By focusing on these aspects, professionals in the manufacturing and processing industry can ensure that their drain trays not only meet functional requirements but also excel in quality and durability. Understanding these factors will ultimately lead to more efficient production and satisfied end-users.

Related news