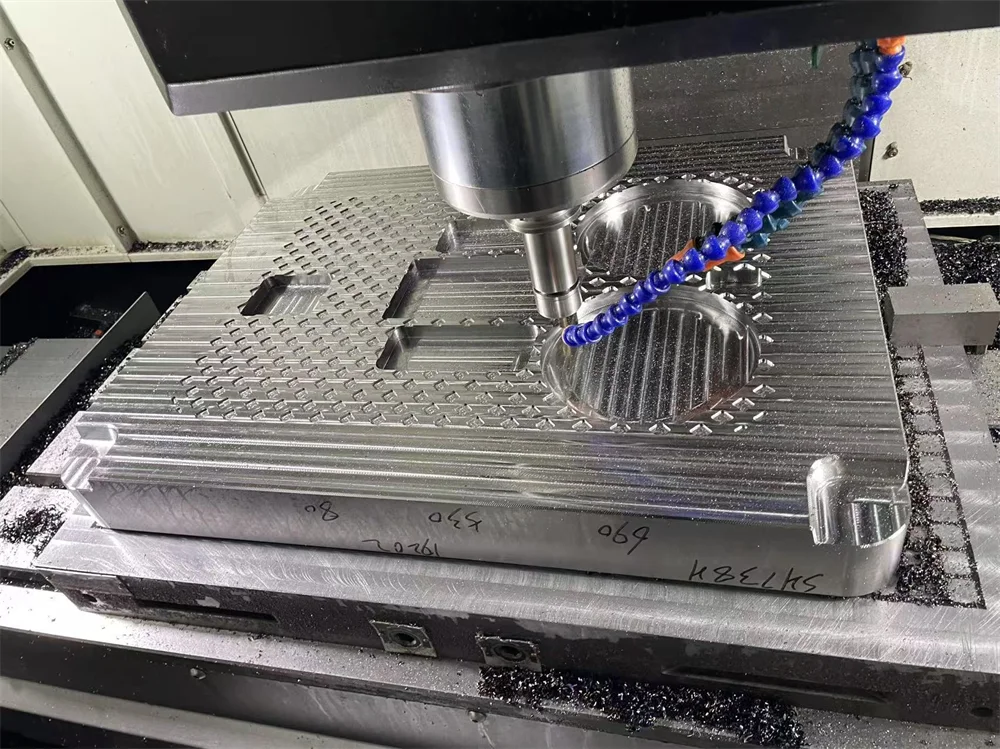

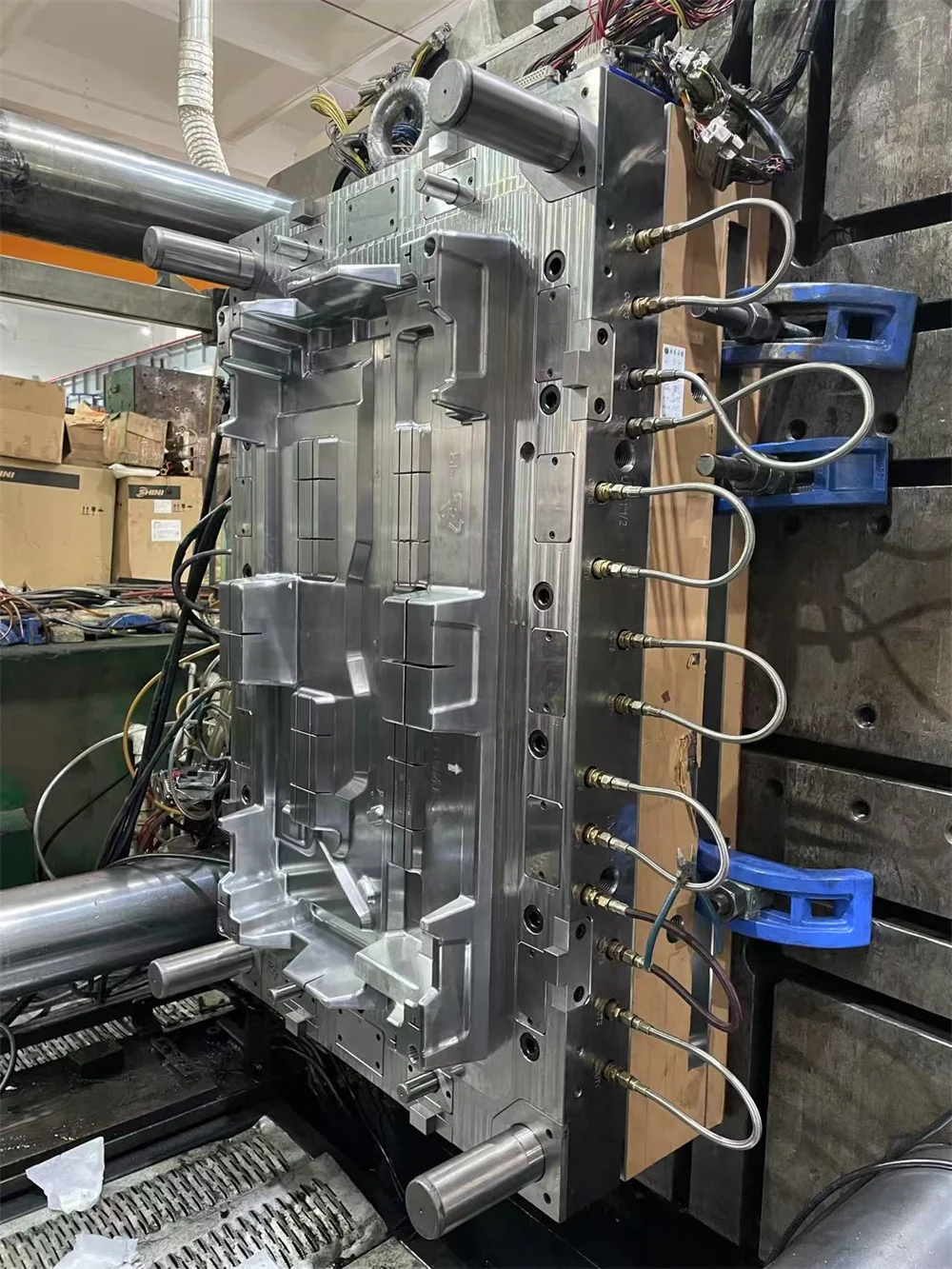

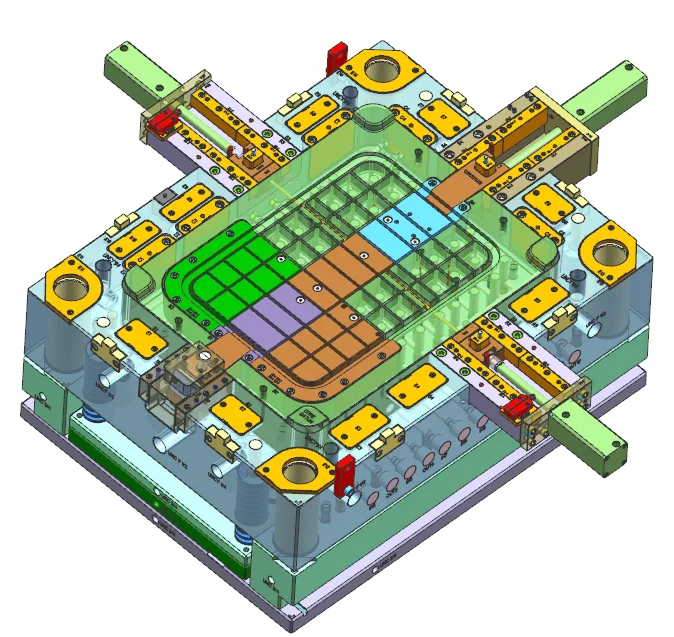

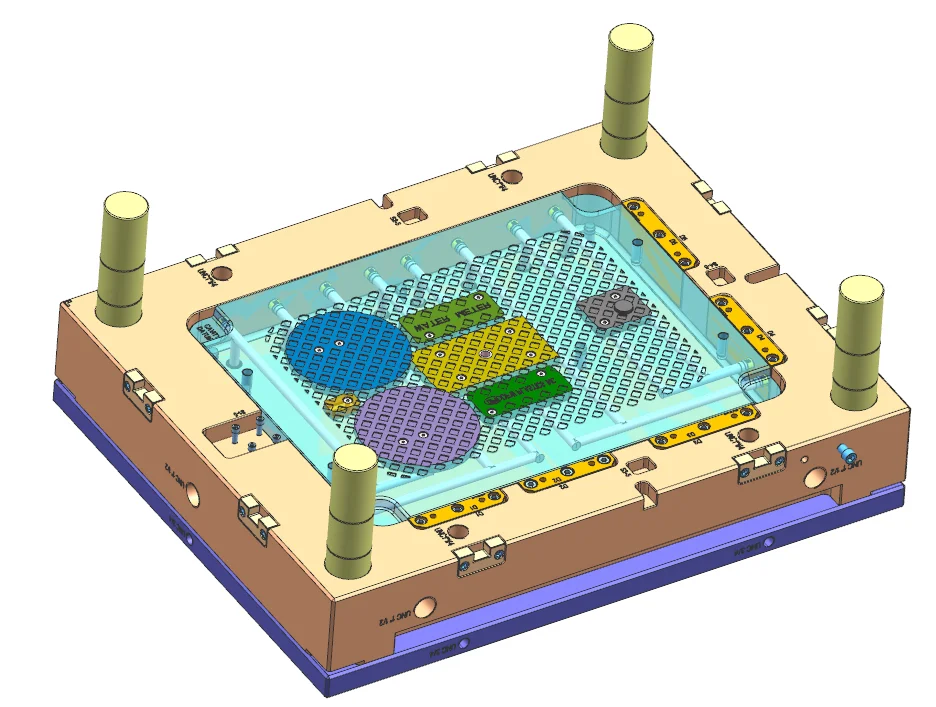

After a custom plastic part has been designed, making a plastic injection mold is the first step in creating custom molded parts. In combination with skilled mold designers, software technology, and the use of expensive CNC machinery, Volitation builds molds for plastic injection that are used to produce high quality molded plastic parts.

Mold is not only the biggest investment in front term of injection project. the prosess of producing is the most important factor of the final products'quality. if you are looking for a company of injection mold, so it is very important to find a supplier which has mold manufacturing capability. only this way, the progress of your project and the quality of your product can be guranteed.

Our injection molding experts look forward to working with you on your mold build project as the next step toward manufacturing your custom molded parts. If you’re looking for an injection mold supplier, we have you covered. E-mail: data@sz-volitation.com

Consult NowManufacturing Process

Model Case

Technology

90% with USA or Europe. Proficientin European and American mold standards, e.g. DME Hasco etc. standard.

Feedback

All inquire will be finished in 12 hours. Will give all feedback in 12 hours. Work timing with 24 hours.

Customer

90% with USA or Europe. Proficientin European and American mold standards, e.g. DME Hasco etc. standard.

Transport

Quickly shipping All molds by sea in one month. All samples in 3 days.

Services

Professional, quick response and have a complete set of service processes to meet customer needs. ODM and OEM services are available.