How Automotive Molds Revolutionize Dashboard Pipe Manufacturing

How Automotive Molds Revolutionize Dashboard Pipe Manufacturing Table of Contents 1. Introduction to Automotive Molds and Their Importance 2. Understanding Dashboard Pipe Manufacturing 3. The Role of Molds in the Manufacturing Process 3.1 Types of Automotive Molds Used 3.2 Materials Used in Mold Production 4. Advantages of Using Automotive Molds 4.1 Precision and Accuracy in Produc

2026-02-11

How Automotive Molds Revolutionize Dashboard Pipe Manufacturing

Table of Contents

1. Introduction to Automotive Molds and Their Importance

2. Understanding Dashboard Pipe Manufacturing

3. The Role of Molds in the Manufacturing Process

3.1 Types of Automotive Molds Used

3.2 Materials Used in Mold Production

4. Advantages of Using Automotive Molds

4.1 Precision and Accuracy in Production

4.2 Cost-Effectiveness and Efficiency

5. Innovations in Automotive Mold Technology

5.1 3D Printing and Its Impact on Mold Creation

5.2 Smart Molds and Automation in Manufacturing

6. Case Studies: Successful Implementations of Automotive Molds

7. Future Trends in Dashboard Pipe Manufacturing

8. Frequently Asked Questions (FAQs)

9. Conclusion

1. Introduction to Automotive Molds and Their Importance

In the rapidly evolving automotive industry, the demand for precision and efficiency is paramount. **Automotive molds**, specifically designed for manufacturing dashboard pipes, play a pivotal role in achieving these standards. These molds are not just tools; they are the backbone of a manufacturing process that ensures vehicles are equipped with durable, high-quality components. By understanding how these molds operate, we can appreciate their significance in the production line.

2. Understanding Dashboard Pipe Manufacturing

Dashboard pipes are essential components that facilitate airflow, wiring, and various functionalities within the vehicle's dashboard. Their design and production must meet stringent safety and aesthetic standards. The manufacturing of these pipes involves several steps, including design, prototyping, and final production. **Automotive molds** streamline this process, allowing for mass production without compromising quality.

3. The Role of Molds in the Manufacturing Process

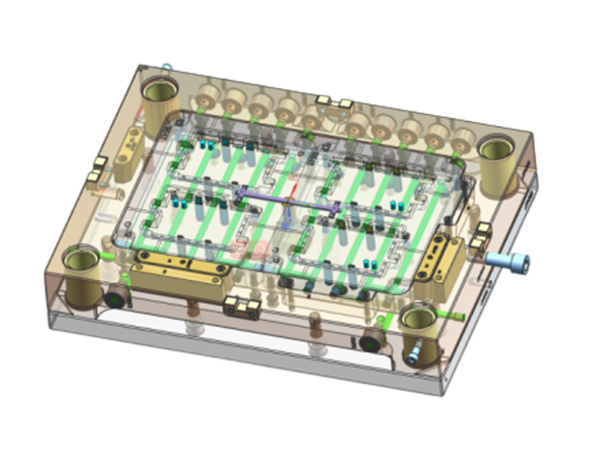

Molds are critical in shaping the various components of dashboard pipes. They determine the final product's dimensions, surface finish, and overall quality. There are several aspects to consider regarding the role of molds:

3.1 Types of Automotive Molds Used

Different types of molds serve unique functions in the production of dashboard pipes. Common types include:

- **Injection Molds**: Widely used for producing plastic parts, injection molds provide high precision and can produce complex shapes.

- **Blow Molds**: Ideal for hollow parts, blow molds are used to create air ducts and other tubular components.

- **Compression Molds**: These molds are suitable for rubber and other composite materials, ensuring durability and flexibility.

3.2 Materials Used in Mold Production

The choice of material for automotive molds can significantly impact the manufacturing process. Common materials include:

- **Steel**: Known for its durability and strength, steel molds are ideal for high-volume production.

- **Aluminum**: Lighter and easier to work with, aluminum molds are often used for prototypes or lower-volume production.

- **Composite Materials**: These are becoming increasingly popular due to their lightweight properties and resistance to wear.

4. Advantages of Using Automotive Molds

Utilizing automotive molds in dashboard pipe manufacturing offers numerous benefits that enhance the overall production process.

4.1 Precision and Accuracy in Production

One of the foremost advantages of using automotive molds is the **precision** they offer. Advanced mold designs enable manufacturers to achieve intricate shapes and tight tolerances. This level of accuracy is crucial for parts that must fit perfectly within the vehicle's dashboard assembly.

4.2 Cost-Effectiveness and Efficiency

Automotive molds are designed for high-volume production, which significantly reduces per-unit costs. By investing in effective mold technology, manufacturers can increase their output while maintaining quality. Automated processes further streamline production, leading to faster turnaround times.

5. Innovations in Automotive Mold Technology

The automotive industry is constantly evolving, and mold technology is no exception. Recent innovations have transformed how molds are created and utilized.

5.1 3D Printing and Its Impact on Mold Creation

3D printing technology has revolutionized the production of automotive molds. This approach allows for rapid prototyping and the creation of complex geometries that traditional methods may not achieve. **3D-printed molds** facilitate quicker design iterations, enabling manufacturers to respond to market changes faster.

5.2 Smart Molds and Automation in Manufacturing

The integration of smart technology into mold design has paved the way for automation in manufacturing. Smart molds equipped with sensors can monitor production processes in real-time, ensuring quality control and reducing waste. Automation not only enhances efficiency but also minimizes labor costs.

6. Case Studies: Successful Implementations of Automotive Molds

Numerous automotive manufacturers have successfully integrated advanced mold technology into their production processes. One notable example is a leading automotive company that adopted **3D printing** for its mold production. By doing so, they reduced lead times by 50% and significantly decreased material waste.

Another case involves a manufacturer that implemented smart sensors in their molds. This innovation allowed for real-time monitoring, which reduced defects by 30%, ensuring a higher-quality product and improved customer satisfaction.

7. Future Trends in Dashboard Pipe Manufacturing

As technology continues to advance, the future of dashboard pipe manufacturing looks promising. Key trends to watch include:

- **Sustainability**: An increasing focus on eco-friendly materials and processes will shape the future of automotive molds.

- **Customization**: As consumer preferences evolve, the demand for customized components will drive innovation in mold technology.

- **Advanced Materials**: The use of lightweight and durable materials will enhance the performance and efficiency of automotive molds.

8. Frequently Asked Questions (FAQs)

What are automotive molds?

Automotive molds are specialized tools used in the manufacturing process to shape components like dashboard pipes. They ensure precision and efficiency in production.

How do automotive molds affect manufacturing efficiency?

Automotive molds streamline the production process by enabling high-volume output with consistent quality, reducing overall costs and time.

What materials are commonly used to create automotive molds?

Common materials for automotive molds include steel, aluminum, and composite materials, each chosen for their specific properties and applications.

What innovations are shaping the future of automotive molds?

Innovations such as 3D printing and smart technologies are transforming automotive mold production, enhancing efficiency and precision.

How do automotive molds contribute to product quality?

By providing high precision and allowing for complex designs, automotive molds significantly enhance the quality and fit of manufactured components.

9. Conclusion

Automotive molds play a crucial role in the manufacturing of dashboard pipes, significantly influencing the quality, efficiency, and cost-effectiveness of production. As technology continues to advance, the future of automotive molds promises further innovations that will lead to enhanced production processes and superior product quality. By investing in advanced mold technology, manufacturers can stay competitive in the ever-evolving automotive landscape, ensuring they meet the demands of consumers and regulatory standards alike.

Related news