Understanding Plastic Injection Molds for Vehicle Trim: Key Insights for Professionals

Plastic injection molds for vehicle trim play a vital role in the automotive manufacturing sector, enabling the production of high-quality, intricate parts that enhance both functionality and aesthetics. These molds are designed to create various interior and exterior components, such as dashboards, door panels, and decorative elements. The efficiency and precision of plastic injection molding all

2026-02-15

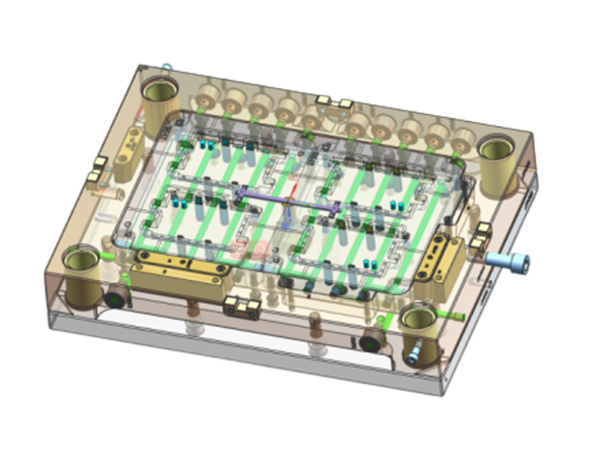

Plastic injection molds for vehicle trim play a vital role in the automotive manufacturing sector, enabling the production of high-quality, intricate parts that enhance both functionality and aesthetics. These molds are designed to create various interior and exterior components, such as dashboards, door panels, and decorative elements. The efficiency and precision of plastic injection molding allow manufacturers to meet the increasing demand for lightweight and durable automotive parts.

The process begins with the design phase, where engineers utilize computer-aided design (CAD) software to create detailed mold designs. This stage is crucial, as it determines the mold's geometry, ensuring that the final product meets the vehicle's specifications. Key factors to consider during the design process include part complexity, material selection, and the intended application of the trim piece, as these elements influence the mold's performance and longevity.

Material selection is another critical aspect when dealing with plastic injection molds for vehicle trim. The common materials used include thermoplastics, which can withstand the rigors of automotive applications. Factors such as temperature resistance, UV stability, and impact strength must be carefully evaluated. Selecting the right material not only ensures the durability of the trim but also affects the molding process, such as cycle times and cooling efficiency.

Once the design is finalized, the manufacturing of the mold itself begins. This involves precision machining techniques to create the mold components, ensuring they fit together seamlessly. Advanced technologies like CNC machining and EDM (Electrical Discharge Machining) are often employed to achieve the desired precision. The quality of the mold directly impacts the final product, making it imperative for manufacturers to maintain high standards throughout the production process.

After the mold is constructed, it's subjected to rigorous testing to ensure that it meets all specifications and performs optimally under production conditions. This phase often includes trial runs to identify any potential issues, allowing for adjustments before full-scale production begins. Effective testing can significantly reduce the risk of defects in the final vehicle trim, enhancing overall quality and customer satisfaction.

Finally, the integration of automation and smart technologies in the injection molding process is becoming increasingly prevalent. These advancements lead to improved efficiency, reduced waste, and enhanced precision, which are crucial for meeting the demands of modern vehicle manufacturing.

In summary, understanding plastic injection molds for vehicle trim encompasses various aspects, from design and material selection to manufacturing and testing. By prioritizing these elements, professionals in the manufacturing sector can ensure the production of high-quality automotive components that meet the evolving needs of the industry.

The process begins with the design phase, where engineers utilize computer-aided design (CAD) software to create detailed mold designs. This stage is crucial, as it determines the mold's geometry, ensuring that the final product meets the vehicle's specifications. Key factors to consider during the design process include part complexity, material selection, and the intended application of the trim piece, as these elements influence the mold's performance and longevity.

Material selection is another critical aspect when dealing with plastic injection molds for vehicle trim. The common materials used include thermoplastics, which can withstand the rigors of automotive applications. Factors such as temperature resistance, UV stability, and impact strength must be carefully evaluated. Selecting the right material not only ensures the durability of the trim but also affects the molding process, such as cycle times and cooling efficiency.

Once the design is finalized, the manufacturing of the mold itself begins. This involves precision machining techniques to create the mold components, ensuring they fit together seamlessly. Advanced technologies like CNC machining and EDM (Electrical Discharge Machining) are often employed to achieve the desired precision. The quality of the mold directly impacts the final product, making it imperative for manufacturers to maintain high standards throughout the production process.

After the mold is constructed, it's subjected to rigorous testing to ensure that it meets all specifications and performs optimally under production conditions. This phase often includes trial runs to identify any potential issues, allowing for adjustments before full-scale production begins. Effective testing can significantly reduce the risk of defects in the final vehicle trim, enhancing overall quality and customer satisfaction.

Finally, the integration of automation and smart technologies in the injection molding process is becoming increasingly prevalent. These advancements lead to improved efficiency, reduced waste, and enhanced precision, which are crucial for meeting the demands of modern vehicle manufacturing.

In summary, understanding plastic injection molds for vehicle trim encompasses various aspects, from design and material selection to manufacturing and testing. By prioritizing these elements, professionals in the manufacturing sector can ensure the production of high-quality automotive components that meet the evolving needs of the industry.

Related news