Automotive Mold Tool For Plastic Radiator Part

The use of automotive mold tools specifically tailored for plastic radiator parts offers numerous advantages that enhance both manufacturing processes and end-product reliability.

2025-09-03

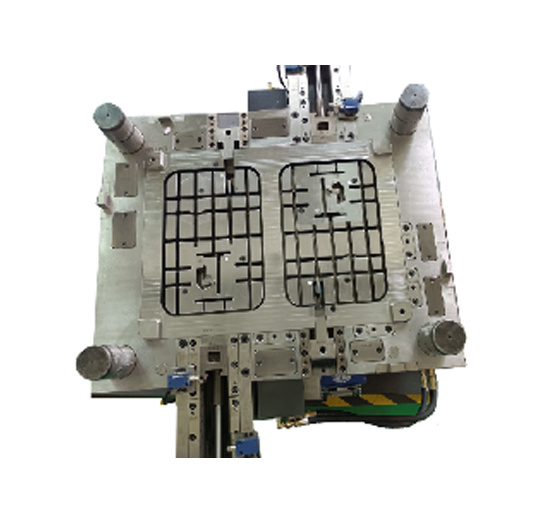

In the automotive industry, mold tools are critical in the production of various components, including plastic radiator parts. These tools are designed to create precise shapes and contours, ensuring that the final products meet stringent quality and performance standards. The process typically involves injecting molten plastic into a mold, allowing it to cool and solidify into the desired form. The use of automotive mold tools specifically tailored for plastic radiator parts offers numerous advantages that enhance both manufacturing processes and end-product reliability.

One of the primary benefits of utilizing mold tools for plastic radiator parts is the high level of accuracy they provide. The design of the mold is meticulously crafted to ensure that each piece is produced with tight tolerances. This precision is crucial in the automotive industry, where even minor discrepancies can lead to significant issues, such as leaks or inefficiencies in the radiator system. By employing advanced mold-making technologies, manufacturers can achieve the exact specifications needed for optimal performance.

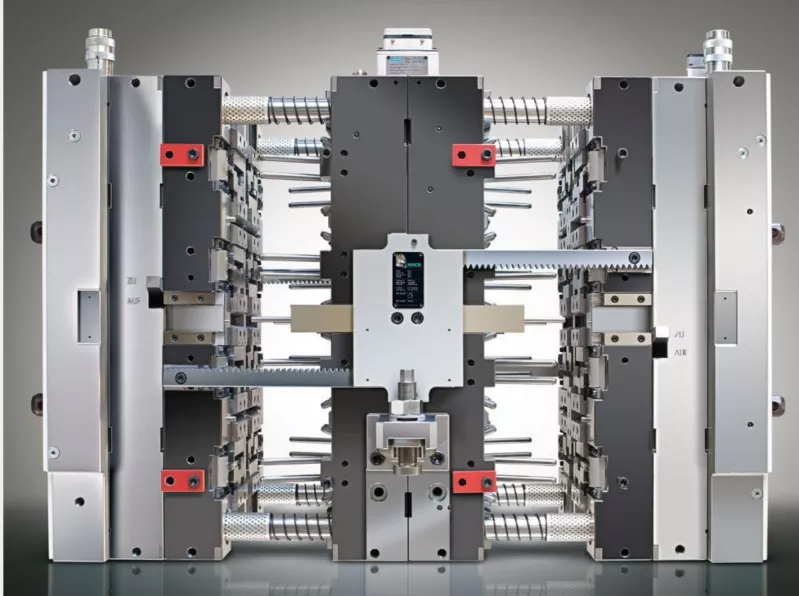

Additionally, automotive mold tools contribute to more efficient production cycles. Once a mold is created, it can be used to produce thousands of identical parts quickly. This scalability reduces the time and labor costs associated with manufacturing, allowing companies to meet market demands more effectively. Furthermore, the repeatability of the molding process ensures that every plastic radiator part produced is consistent in quality, which is vital for maintaining the reliability of automotive systems.

Another significant aspect of using mold tools in producing plastic radiator parts is the potential for material optimization. Modern plastics used in radiator manufacturing often possess excellent thermal and chemical resistance, which is essential in a car's cooling system. Mold tools can be designed to accommodate these advanced materials, ensuring that the characteristics of the plastic are fully utilized. This adaptation not only enhances the performance of the radiator but also contributes to the overall efficiency of the vehicle.

Moreover, the ability of mold tools to create complex geometries allows for innovative designs in radiator parts. This flexibility enables engineers and designers to explore new shapes and structures that can improve airflow and cooling efficiency. As a result, the development of more efficient radiator systems can lead to better fuel economy and reduced emissions in vehicles.

In conclusion, automotive mold tools for plastic radiator parts play a vital role in the automotive industry, ensuring high-quality production, efficiency, and the ability to innovate. Understanding their capabilities and benefits is essential for manufacturers aiming to stay competitive in a fast-evolving market. By leveraging advanced mold-making technologies, companies can enhance the performance and reliability of their automotive components, ultimately contributing to safer and more efficient vehicles on the road.

Related news