The Science of Injection Molding and Its Impact on Peugeot Parts

The Science of Injection Molding and Its Impact on Peugeot Parts Table of Contents Introduction to Injection Molding History of Injection Molding The Injection Molding Process Explained Preparation of Materials Injection Phase Cooling and Ejection Materials Used in Injection Molding Applications of Injection Molding in Peug

2025-09-09

The Science of Injection Molding and Its Impact on Peugeot Parts

Table of Contents

- Introduction to Injection Molding

- History of Injection Molding

- The Injection Molding Process Explained

- Materials Used in Injection Molding

- Applications of Injection Molding in Peugeot Parts

- Benefits of Injection Molding for Peugeot

- Challenges in Injection Molding

- The Future of Injection Molding in the Automotive Industry

- Conclusion

- Frequently Asked Questions

Introduction to Injection Molding

Injection molding stands as one of the most pivotal manufacturing processes in the production of automotive parts, particularly for leading brands like Peugeot. This technique involves injecting molten material into a mold, allowing for the efficient and precise fabrication of complex components. As we explore the intricacies of injection molding, we will unveil its significance, especially in the context of Peugeot parts, emphasizing how science and technology converge to optimize automotive manufacturing.

History of Injection Molding

The origins of injection molding can be traced back to the early 19th century when it was primarily used for creating simple shapes from materials like rubber. Over the decades, the process evolved significantly with the introduction of thermoplastics in the 1940s. This evolution led to widespread industrial applications, including the automotive sector. Peugeot, recognizing the potential of injection molding, began integrating this technology into their manufacturing processes in the latter half of the 20th century, thereby enhancing their production capabilities and product quality.

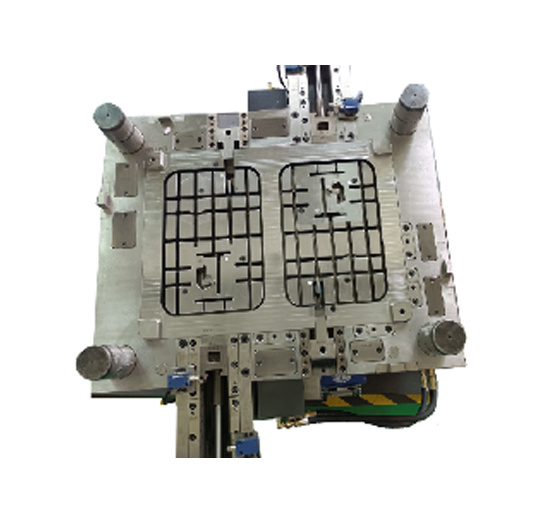

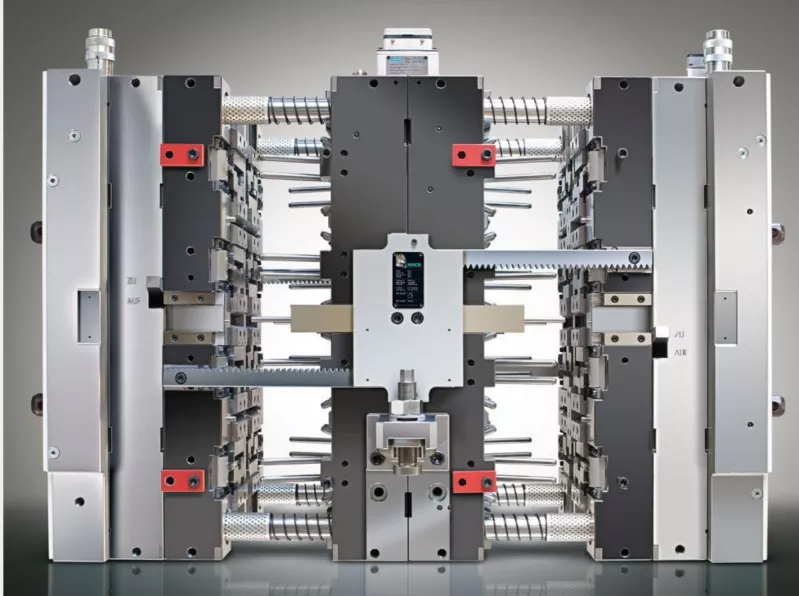

The Injection Molding Process Explained

Understanding the injection molding process is crucial to grasping its impact on Peugeot parts. This process consists of several key phases that ensure high precision and efficiency in manufacturing.

Preparation of Materials

Before the actual molding begins, the selected raw materials undergo thorough preparation. This stage involves drying the thermoplastic pellets to eliminate moisture, which could compromise the quality of the final product. The choice of materials, often polycarbonate or polypropylene, plays a significant role in determining the strength and durability of the parts produced.

Injection Phase

In this phase, the dried pellets are heated until they melt, transforming into a viscous liquid. The liquid is then injected into a mold at high pressure. This pressure is crucial as it ensures that the material fills the intricate shapes of the mold accurately, thereby capturing every detail needed for the part. The precision in this phase directly influences the part's fit and function within Peugeot vehicles.

Cooling and Ejection

Once the mold is filled, the molten material must cool and solidify. This cooling phase is vital as it determines the part's final dimensions and structural integrity. After cooling, the mold opens, and the newly formed part is ejected. The efficiency of this process minimizes cycle times, allowing Peugeot to produce parts rapidly and at scale.

Materials Used in Injection Molding

The selection of materials for injection molding is critical, especially in the automotive sector. Peugeot relies on a variety of thermoplastics and thermosetting plastics to meet their stringent quality standards. Common materials include:

- **Acrylonitrile Butadiene Styrene (ABS):** Known for its impact resistance and toughness, making it ideal for components exposed to potential stress.

- **Polypropylene (PP):** Lightweight and resistant to chemicals, PP is often used in interior and exterior parts of Peugeot vehicles.

- **Polycarbonate (PC):** This material offers excellent optical clarity and is commonly used in lighting components.

- **Nylon (PA):** Renowned for its strength and durability, nylon is frequently used in functional components that require high performance.

Applications of Injection Molding in Peugeot Parts

Injection molding finds extensive applications across various Peugeot parts, contributing to the brand's commitment to quality and innovation. Key applications include:

- **Exterior Components:** Bumpers and trim pieces that require both aesthetic appeal and durability.

- **Interior Components:** Dashboard parts, switch panels, and other interior fittings that demand precise engineering.

- **Functional Parts:** Engine covers, air ducts, and other components that must withstand high temperatures and mechanical stresses.

- **Lighting Systems:** Headlight and taillight housings that combine functionality with design.

Benefits of Injection Molding for Peugeot

The advantages of injection molding are numerous and play a significant role in Peugeot's production efficiency, including:

- **Cost Efficiency:** High-volume production leads to lower per-unit costs, making it economically viable for mass production.

- **Design Flexibility:** Injection molding allows for intricate designs that might be challenging or impossible with other manufacturing methods.

- **Material Efficiency:** Minimal waste is produced during the process, as excess material can often be reused.

- **Consistency and Quality:** The automated nature of injection molding ensures uniformity in parts, adhering to Peugeot's high-quality standards.

Challenges in Injection Molding

Despite its numerous benefits, injection molding comes with its own set of challenges. Key challenges include:

- **Tooling Costs:** Initial setup costs for molds can be significant, posing a barrier for smaller production runs.

- **Material Limitations:** Not all materials are suitable for injection molding, which can limit design options.

- **Cycle Time Management:** Optimizing the cooling and ejection phases is essential to reduce cycle times and maximize throughput.

The Future of Injection Molding in the Automotive Industry

As technology continues to advance, the future of injection molding in the automotive industry looks promising. Innovations such as 3D printing and advanced robotics are expected to enhance efficiency further. For Peugeot, embracing these technologies will likely result in even more sophisticated parts and reduced production times, solidifying their position as a leader in automotive manufacturing.

Conclusion

Injection molding is a cornerstone of modern manufacturing, particularly in the automotive sector. For Peugeot, this process not only facilitates the production of high-quality parts but also enhances efficiency and reduces costs. By understanding the science behind injection molding, we can appreciate its profound impact on the automotive industry and the continuous innovation it brings. As we look to the future, it is clear that injection molding will remain integral to Peugeot's commitment to excellence in automotive engineering.

Frequently Asked Questions

1. What materials are commonly used in injection molding for Peugeot parts?

The most commonly used materials include Acrylonitrile Butadiene Styrene (ABS), Polypropylene (PP), Polycarbonate (PC), and Nylon (PA) due to their strength and durability.

2. How does injection molding improve production efficiency?

Injection molding allows for high-volume production with low per-unit costs and rapid cycle times, significantly improving overall production efficiency.

3. What are the primary applications of injection molding in Peugeot vehicles?

Injection molding is used for exterior components like bumpers, interior parts such as dashboards, functional parts like engine covers, and lighting systems.

4. What are the advantages of using injection molding over other manufacturing processes?

The advantages include cost efficiency, design flexibility, minimal waste, and high consistency and quality in the produced parts.

5. What challenges does the injection molding process face?

Challenges include high initial tooling costs, material limitations, and the need for effective cycle time management to maximize production efficiency.

Related news