The Benefits of Two Shot Injection Molding for Automotive Interiors

The Benefits of Two Shot Injection Molding for Automotive Interiors Introduction to Two Shot Injection Molding Two shot injection molding is revolutionizing the automotive industry by offering a method that caters to modern design and manufacturing needs. This advanced process allows for the simultaneous injection of two different materials into a single mold, resulting in parts that possess enhan

2025-08-30

The Benefits of Two Shot Injection Molding for Automotive Interiors

Introduction to Two Shot Injection Molding

Two shot injection molding is revolutionizing the automotive industry by offering a method that caters to modern design and manufacturing needs. This advanced process allows for the simultaneous injection of two different materials into a single mold, resulting in parts that possess enhanced functionality and aesthetics. In the context of automotive interiors, two shot molding significantly contributes to both the performance and visual appeal of various components.

Understanding the Process of Two Shot Injection Molding

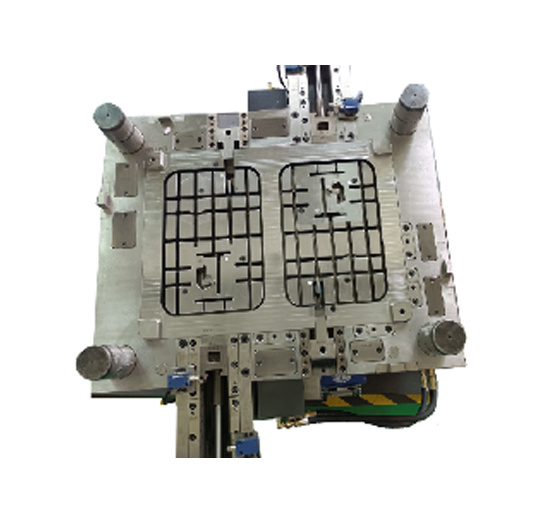

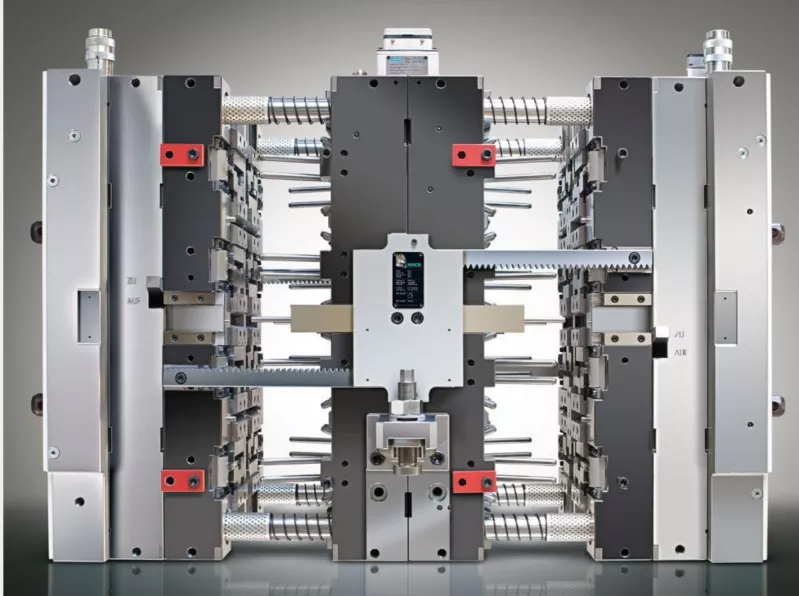

The two shot injection molding process involves several critical steps:

Step 1: Material Selection

Choosing the right materials is essential for achieving the desired properties in the final automotive part. Typically, one material is rigid, while the other is softer, enabling a variety of textures and functionalities.

Step 2: Pre-Molding

In this stage, the first material is injected into a mold, creating the base layer of the part. This layer is often made from a durable thermoplastic that can withstand the automotive environment.

Step 3: Second Injection

After the first layer has cooled and solidified, the second material is injected. This layer often provides a softer touch, such as a rubberized finish for better grip and comfort.

Step 4: Cooling and Ejection

Once both layers are injected and cooled, the completed part is ejected from the mold, ready for further assembly and integration into the vehicle.

Key Advantages of Two Shot Injection Molding

Understanding the benefits of two shot injection molding is crucial for manufacturers and designers in the automotive industry. Here are the primary advantages:

Enhanced Design Flexibility

One of the most significant benefits of two shot injection molding is the **flexibility it offers in design**. Manufacturers can create intricate shapes and complex geometries that would be challenging or impossible with traditional single-material processes. This flexibility allows automotive designers to innovate and push the boundaries of interior aesthetics.

Improved Part Performance and Functionality

Parts produced through two shot injection molding benefit from the combined strengths of two different materials. For instance, a rigid outer layer can provide structural support while a softer inner layer can enhance user comfort. This combination results in **improved performance** of automotive interiors, making components more robust and longer-lasting.

Cost Efficiency in Production

While the initial investment in two shot injection molding technology may be higher, the long-term cost efficiency is a significant advantage. The process reduces the need for multiple manufacturing steps, which can lower labor costs and minimize production time. Additionally, the reduced waste associated with this process contributes to overall cost saving.

Reduced Assembly Time

Traditional methods often require multiple parts to be molded separately and assembled later. Two shot injection molding eliminates the need for this additional assembly phase, streamlining the production process. This efficiency results in **faster time-to-market** for new automotive models.

Enhanced Aesthetics and Customization

The ability to incorporate different materials allows for **greater aesthetic appeal**. Manufacturers can easily introduce various colors, textures, and finishes into a single part, allowing for a high degree of customization. This feature gives automotive brands the opportunity to distinguish themselves in a competitive market through unique interior designs.

Applications in Automotive Interiors

The two shot injection molding process has vast applications within automotive interiors, enhancing various components:

Dashboard Components

Dashboards are critical to the overall driving experience, and two shot injection molding allows manufacturers to create components that are not only visually appealing but also functional. The combination of hard and soft materials can improve both the look and the feel of the dashboard, enhancing driver comfort.

Door Panels

Door panels benefit significantly from two shot molding, allowing manufacturers to integrate soft-touch surfaces with rigid structures. This combination enhances durability while improving the overall comfort and aesthetics of the vehicle's interior.

Seating Components

Seating is another critical area where two shot injection molding shines. It allows for the creation of comfortable surfaces with different textures, ensuring a pleasant ride for passengers. Additionally, the integration of various materials can improve the durability of the seats.

Instrument Panels

Instrument panels require a delicate balance of functionality and aesthetic appeal. Two shot injection molding enables manufacturers to create panels that not only meet the necessary performance standards but also enhance the overall visual experience of the interior.

Environmental Impact and Sustainability

As the automotive industry moves towards sustainability, two shot injection molding presents several environmental benefits. This method generates less waste than traditional manufacturing processes, thus contributing to a reduced carbon footprint. Moreover, the ability to use recycled materials in two shot molding aligns with the growing demand for sustainable practices in manufacturing.

Recyclability of Materials

Many of the materials used in two shot injection molding are recyclable. This characteristic allows manufacturers to adopt a more sustainable approach to production, minimizing their impact on the environment while still delivering high-quality automotive interiors.

Energy Efficiency

The streamlined production process associated with two shot injection molding typically requires less energy than traditional methods. This energy efficiency not only lowers production costs but also contributes to a more sustainable manufacturing model.

Challenges and Considerations

Despite its numerous benefits, two shot injection molding does come with its own set of challenges:

Higher Initial Investment

Investing in two shot injection molding technology may require a significant upfront cost. Manufacturers must assess whether the long-term savings outweigh the initial investment to determine if this technology is right for their operations.

Material Compatibility

Choosing materials that work well together is critical to the success of two shot injection molding. Incompatible materials can lead to poor bonding and affect the integrity of the final product. Manufacturers must carefully select their materials to ensure optimal performance.

Future Trends in Two Shot Injection Molding for Automotive Interiors

As technology continues to advance, the future of two shot injection molding in automotive interiors looks promising:

Integration with Smart Technologies

As vehicles become more intelligent, there will be opportunities to integrate smart technologies into interior components using two shot injection molding. Sensors and displays can be seamlessly embedded into parts, enhancing functionality without compromising aesthetics.

Advancements in Material Science

Ongoing research into advanced materials will likely improve the performance and capabilities of two shot injection molding. New materials that offer enhanced durability, flexibility, and recyclability will further drive innovation in automotive interiors.

Conclusion

Two shot injection molding represents a significant advancement in automotive manufacturing, particularly in the creation of innovative and visually appealing interiors. Its numerous benefits, including improved design flexibility, cost efficiency, and enhanced aesthetics, make it a valuable process for modern automotive production. As the industry continues to embrace sustainability and technological advancements, the role of two shot injection molding will only become more critical in shaping the future of automotive interiors. By understanding its applications and advantages, manufacturers can leverage this powerful process to stay competitive in an ever-evolving market.

FAQs

1. What is two shot injection molding?

Two shot injection molding is a manufacturing process that uses two different materials to create a single part, enhancing both functionality and aesthetics.

2. What are the main benefits of using two shot injection molding in automotive interiors?

The primary benefits include enhanced design flexibility, improved performance, cost efficiency, reduced assembly time, and greater aesthetic customization.

3. How does two shot injection molding impact sustainability in automotive manufacturing?

This process generates less waste and allows for the use of recyclable materials, making it a more sustainable option compared to traditional manufacturing methods.

4. What types of automotive components can be produced using two shot injection molding?

Common applications include dashboard components, door panels, seating components, and instrument panels.

5. What are the challenges associated with two shot injection molding?

Challenges include the higher initial investment required and the need for compatible materials to ensure proper bonding and performance of the final product.

Related news