Understanding Two Component Injection Molding: A Key Technology in Automotive Electrical Components

Two component injection molding (2K molding) is an innovative manufacturing technique that has gained considerable traction within the automotive industry, particularly in the production of electrical components. This process involves the simultaneous injection of two different materials into a mold, resulting in a single, integrated part with enhanced functionality and performance characteristics

2025-09-14

Two component injection molding (2K molding) is an innovative manufacturing technique that has gained considerable traction within the automotive industry, particularly in the production of electrical components. This process involves the simultaneous injection of two different materials into a mold, resulting in a single, integrated part with enhanced functionality and performance characteristics. The ability to combine materials with different properties—such as rigidity, flexibility, and color—allows manufacturers to create components that meet the specific demands of modern automotive design.

One of the primary advantages of two component injection molding is its efficiency. This method reduces the need for assembly operations, as multiple materials can be combined in a single shot. For automotive electrical components, this translates into reduced production times and lower labor costs, making it an attractive option for manufacturers looking to optimize their processes. Additionally, the integration of multiple materials can improve the overall performance of the part, such as enhancing its durability, providing better insulation, or incorporating aesthetic features like color divisions or textures.

In the context of automotive electronics, two component injection molding plays a crucial role in producing components that require both electrical insulation and structural integrity. For instance, connectors, switches, and housings can benefit from this technology, enabling the creation of parts that are not only functional but also visually appealing. Furthermore, the ability to customize materials allows for the design of components that can withstand harsh automotive environments, such as extreme temperatures and exposure to chemicals.

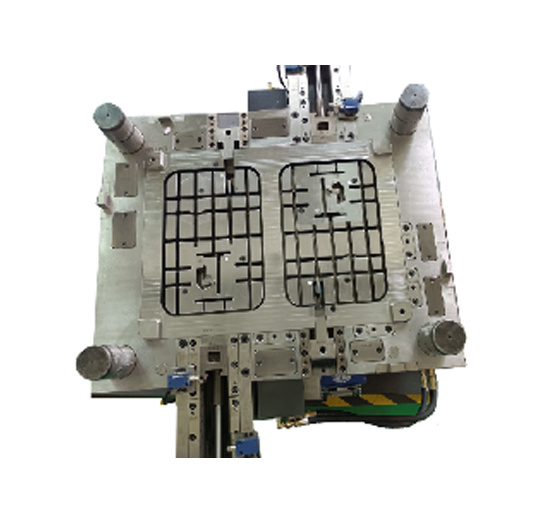

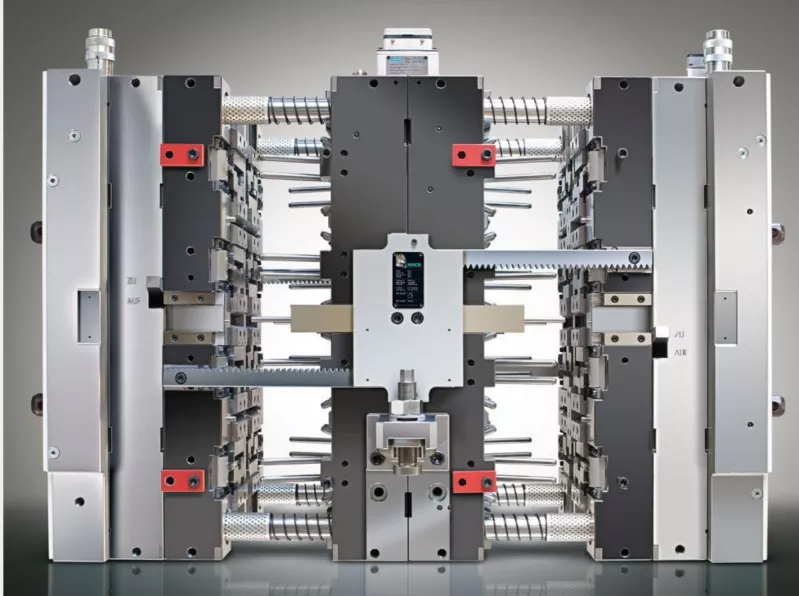

The process of two component injection molding typically involves a specialized injection molding machine equipped with two material feed systems. The materials, often a combination of thermoplastics or thermosets, are heated and mixed before being injected into the mold. The mold design is critical, as it must accommodate the two materials and ensure proper flow and adhesion between them. Careful consideration of the material properties and the intended application is essential to achieve the desired results.

In conclusion, two component injection molding is a vital technology in the automotive industry, particularly for the production of electrical components. Its ability to combine different materials allows for the creation of parts that meet the specific requirements of modern vehicles, enhancing both performance and aesthetics. As the automotive landscape continues to evolve, the adoption of advanced manufacturing techniques like 2K molding will play a significant role in pushing the boundaries of design and functionality in automotive electronics. Companies looking to stay competitive in this sector should consider the benefits of integrating two component injection molding into their production processes.

One of the primary advantages of two component injection molding is its efficiency. This method reduces the need for assembly operations, as multiple materials can be combined in a single shot. For automotive electrical components, this translates into reduced production times and lower labor costs, making it an attractive option for manufacturers looking to optimize their processes. Additionally, the integration of multiple materials can improve the overall performance of the part, such as enhancing its durability, providing better insulation, or incorporating aesthetic features like color divisions or textures.

In the context of automotive electronics, two component injection molding plays a crucial role in producing components that require both electrical insulation and structural integrity. For instance, connectors, switches, and housings can benefit from this technology, enabling the creation of parts that are not only functional but also visually appealing. Furthermore, the ability to customize materials allows for the design of components that can withstand harsh automotive environments, such as extreme temperatures and exposure to chemicals.

The process of two component injection molding typically involves a specialized injection molding machine equipped with two material feed systems. The materials, often a combination of thermoplastics or thermosets, are heated and mixed before being injected into the mold. The mold design is critical, as it must accommodate the two materials and ensure proper flow and adhesion between them. Careful consideration of the material properties and the intended application is essential to achieve the desired results.

In conclusion, two component injection molding is a vital technology in the automotive industry, particularly for the production of electrical components. Its ability to combine different materials allows for the creation of parts that meet the specific requirements of modern vehicles, enhancing both performance and aesthetics. As the automotive landscape continues to evolve, the adoption of advanced manufacturing techniques like 2K molding will play a significant role in pushing the boundaries of design and functionality in automotive electronics. Companies looking to stay competitive in this sector should consider the benefits of integrating two component injection molding into their production processes.

Related news