Why Stack Molds Are Revolutionizing Auto Part Molding Processes

Why Stack Molds Are Revolutionizing Auto Part Molding Processes Table of Contents Introduction to Stack Molds What Are Stack Molds? Advantages of Stack Molds in Auto Parts Manufacturing Enhanced Production Efficiency Cost-Effectiveness Improved Part Quality How Stack Molds Work Applications of Stack Molds in the Automo

2025-09-19

Why Stack Molds Are Revolutionizing Auto Part Molding Processes

Table of Contents

- Introduction to Stack Molds

- What Are Stack Molds?

- Advantages of Stack Molds in Auto Parts Manufacturing

- How Stack Molds Work

- Applications of Stack Molds in the Automotive Industry

- The Future of Stack Molding Technology

- Challenges and Considerations in Using Stack Molds

- Conclusion

- FAQs

Introduction to Stack Molds

The automotive industry is experiencing a profound transformation, and one of the driving forces behind this revolution is the innovation in manufacturing techniques. Among these innovations, **stack molds** have emerged as a game-changing technology in the fabrication of auto parts. These molds are not just improving the way parts are made; they are redefining the very standards of efficiency, quality, and cost-effectiveness in auto manufacturing processes.

What Are Stack Molds?

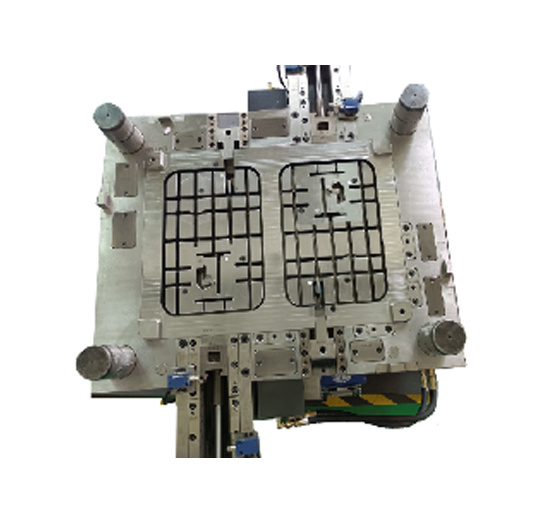

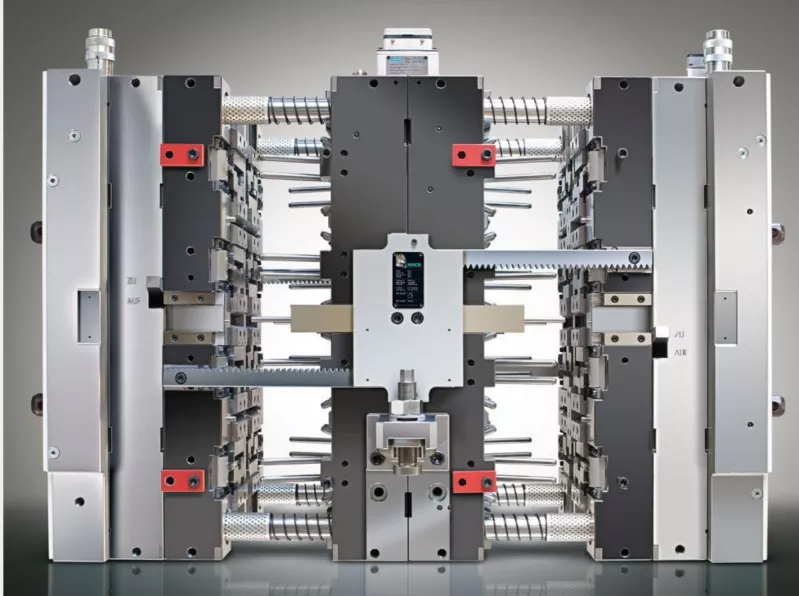

Stack molds are advanced injection molding tools that incorporate multiple layers or levels in a single mold. Unlike traditional injection molds that typically have a single cavity, stack molds can produce multiple parts simultaneously by using two or more layers. This design allows manufacturers to produce several identical parts in one cycle, significantly increasing productivity.

The basic structure of a stack mold includes two or more mold halves, each containing a cavity. As the molding process occurs, the material is injected into these cavities, forming the desired part shape. The ability to stack multiple cavities not only saves time but also reduces material waste, making stack molds an attractive option for automotive manufacturers aiming for sustainability and efficiency.

Advantages of Stack Molds in Auto Parts Manufacturing

As the automotive industry continues to evolve, the need for more efficient production methods becomes apparent. Here, we explore the key advantages that stack molds offer in the manufacturing of auto parts.

Enhanced Production Efficiency

One of the most significant benefits of stack molds is their ability to **boost production efficiency**. By allowing multiple parts to be produced in a single molding cycle, manufacturers can drastically reduce the time taken for each production run. This efficiency not only leads to faster turnaround times but also enables manufacturers to meet increasing market demands without compromising quality.

Cost-Effectiveness

The cost implications of incorporating stack molds into the manufacturing process are substantial. With the ability to produce multiple parts simultaneously, organizations can lower their production costs significantly. Reduced cycle times mean less energy consumption, and the efficiency gained allows for better allocation of resources. Consequently, stack molds can lead to lower labor costs and decreased material expenses, providing manufacturers with a competitive edge in pricing.

Improved Part Quality

Quality is paramount in the automotive industry, where safety and reliability are non-negotiable. Stack molds facilitate a more uniform distribution of material, resulting in parts that are consistently of high quality. Furthermore, the advanced technology used in stack molding minimizes the likelihood of defects, ensuring that each part meets stringent industry standards.

How Stack Molds Work

The operation of stack molds is based on a clever engineering principle that maximizes output while minimizing waste. Here’s a detailed look at how stack molds function:

1. **Material Injection**: The process begins with the injection of molten plastic or other materials into the mold cavities. The design of stack molds typically includes multiple injection points, enabling the material to fill several cavities at once.

2. **Cooling and Ejection**: After the cavities are filled, the material is allowed to cool and solidify. Once the parts have hardened, the mold opens, and the finished parts are ejected simultaneously.

3. **Cycle Repetition**: The cycle is then repeated, allowing for efficient mass production of auto parts.

This streamlined process is what sets stack molds apart from traditional molding techniques, making them an appealing choice for auto part manufacturers.

Applications of Stack Molds in the Automotive Industry

Stack molds are versatile and applicable across various segments of the automotive industry. Here are some specific applications that highlight their effectiveness:

- **Interior Components**: Many interior components, such as dashboard panels and trim pieces, benefit from the precision and efficiency of stack molds. The ability to create complex geometries in a single production run is invaluable for these applications.

- **Exterior Parts**: From bumpers to body panels, stack molds facilitate the production of durable and lightweight exterior components that comply with safety and aesthetic standards.

- **Electrical Components**: With the growing demand for innovative automotive electronics, stack molds are frequently used in the production of housings and connectors. Their efficiency ensures that manufacturers can keep pace with technological advancements.

- **Automotive Accessories**: Accessories, ranging from custom fit mats to storage solutions, can also be efficiently manufactured using stack molds, allowing for customization while maintaining high production rates.

The Future of Stack Molding Technology

As the automotive industry pushes towards sustainability and efficiency, the future of stack molding technology looks promising. Innovations such as **smart manufacturing** and **Industry 4.0** principles are set to further enhance the capabilities of stack molds. Integration with automation and data analytics will allow for real-time monitoring and optimization of the production process, leading to even greater efficiencies.

Moreover, advancements in materials science may lead to the development of new, more adaptable materials that can be used in stack molding. This evolution will open up new possibilities for automotive design and production, ensuring that manufacturers remain at the forefront of innovation.

Challenges and Considerations in Using Stack Molds

Despite the many advantages of stack molds, there are challenges that manufacturers must consider:

- **Initial Investment**: The cost of developing and implementing stack molds can be significant. Companies need to weigh this initial expense against the long-term benefits of increased efficiency and reduced costs.

- **Complexity**: The design and maintenance of stack molds require specialized knowledge and skills. Manufacturers must ensure that their teams are adequately trained to handle these advanced systems.

- **Material Limitations**: Not all materials are suitable for stack molding. Manufacturers need to carefully assess material compatibility and performance to ensure optimal results.

Conclusion

Stack molds are undoubtedly revolutionizing the auto part molding processes by driving production efficiency, lowering costs, and enhancing part quality. Their ability to produce multiple parts simultaneously allows manufacturers to meet the escalating demands of the automotive industry while maintaining high standards of quality.

As technology continues to advance, the future of stack molding is filled with potential innovations that promise to further enhance the capabilities of the automotive manufacturing sector. By embracing stack molds, companies can position themselves at the forefront of the industry, ready to tackle the challenges and opportunities of tomorrow.

FAQs

1. What types of materials can be used with stack molds?

Stack molds can accommodate various materials, including thermoplastics, thermosetting plastics, and certain metals, depending on the mold design and intended application.

2. How does stack molding compare to traditional molding techniques?

Stack molding is more efficient than traditional molding as it produces multiple parts in a single cycle, reducing production time and costs while enhancing quality.

3. What industries besides automotive can benefit from stack molds?

Various industries, including consumer goods, electronics, and medical supplies, can also leverage stack molds for efficient part production.

4. Are stack molds suitable for small-batch production?

While stack molds excel in high-volume production, they can also be adapted for small-batch runs, though the initial investment may be higher compared to traditional molds.

5. What are the maintenance requirements for stack molds?

Regular maintenance is crucial for stack molds to ensure optimal performance. This includes routine inspections, cleaning, and addressing any wear or damage promptly.

By understanding and implementing stack molds in the auto part manufacturing process, companies can not only improve their operations but also contribute positively to the industry's evolution.

Related news