Understanding Injection Molding for Vehicle Air Inlet Pipe Manufacturing

Injection molding is a pivotal manufacturing process widely used in the automotive industry, particularly for components like vehicle air inlet pipes. These pipes serve a critical function in directing air into the engine, ensuring optimal performance and efficiency of the vehicle. The injection molding technique enables manufacturers to create complex shapes with high precision, making it ideal f

2025-09-04

Injection molding is a pivotal manufacturing process widely used in the automotive industry, particularly for components like vehicle air inlet pipes. These pipes serve a critical function in directing air into the engine, ensuring optimal performance and efficiency of the vehicle. The injection molding technique enables manufacturers to create complex shapes with high precision, making it ideal for producing air inlet pipes that meet stringent automotive standards.

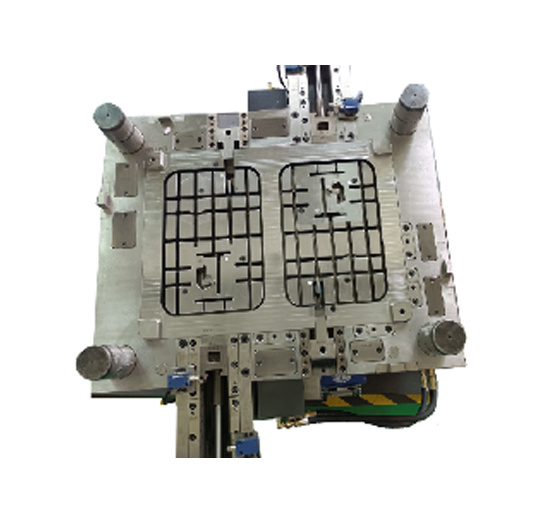

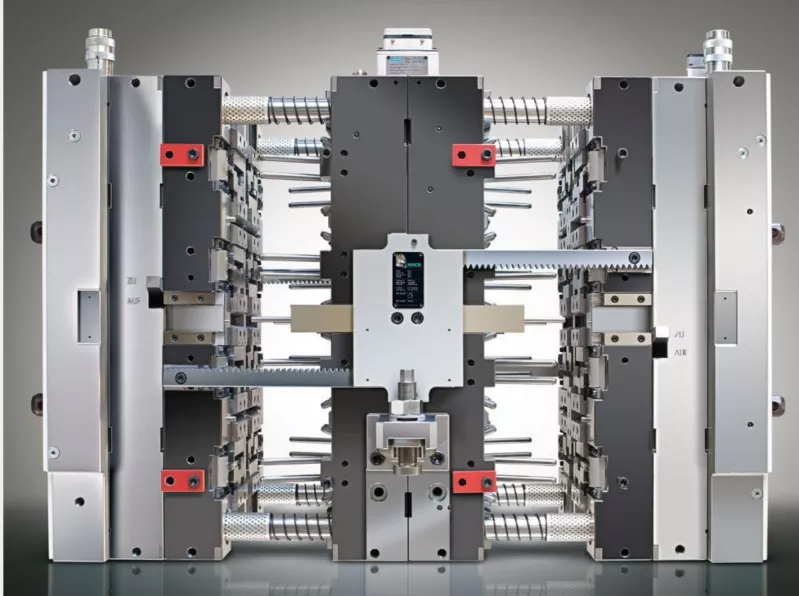

The process begins with the creation of a mold, which is designed to the specific dimensions and requirements of the air inlet pipe. Typically, molds are made from steel or aluminum, materials chosen for their durability and ability to withstand the high pressures involved in injection molding. Once the mold is prepared, plastic pellets, often thermoplastics, are heated until melted and injected into the mold cavity. After cooling, the solidified component is ejected from the mold, and any excess material is trimmed away.

One of the significant advantages of injection molding for vehicle air inlet pipes is the ability to produce large quantities with remarkable consistency. This mass production capability is vital in the automotive sector, where high demand for parts necessitates efficient manufacturing solutions. Additionally, injection molding allows for intricate designs, which are essential for optimizing airflow and ensuring that the air inlet pipe fits seamlessly within the vehicle's architecture.

Moreover, the material selection in the injection molding process greatly impacts the performance and durability of the air inlet pipe. Manufacturers often choose materials like polypropylene or nylon, known for their lightweight properties and resistance to heat and chemicals. This selection not only contributes to the overall performance of the vehicle but also aids in meeting regulatory standards concerning emissions and fuel efficiency.

In conclusion, the application of injection molding in the production of vehicle air inlet pipes exemplifies the intersection of technology and automotive design. As advancements in materials and molding techniques continue to evolve, the potential for innovation in vehicle components remains vast. Understanding this process is crucial for professionals within the automotive sector, as it directly influences both the functionality and efficiency of modern vehicles. By leveraging the capabilities of injection molding, manufacturers can ensure the production of high-quality, reliable air inlet pipes that support the performance demands of today’s automobiles.

The process begins with the creation of a mold, which is designed to the specific dimensions and requirements of the air inlet pipe. Typically, molds are made from steel or aluminum, materials chosen for their durability and ability to withstand the high pressures involved in injection molding. Once the mold is prepared, plastic pellets, often thermoplastics, are heated until melted and injected into the mold cavity. After cooling, the solidified component is ejected from the mold, and any excess material is trimmed away.

One of the significant advantages of injection molding for vehicle air inlet pipes is the ability to produce large quantities with remarkable consistency. This mass production capability is vital in the automotive sector, where high demand for parts necessitates efficient manufacturing solutions. Additionally, injection molding allows for intricate designs, which are essential for optimizing airflow and ensuring that the air inlet pipe fits seamlessly within the vehicle's architecture.

Moreover, the material selection in the injection molding process greatly impacts the performance and durability of the air inlet pipe. Manufacturers often choose materials like polypropylene or nylon, known for their lightweight properties and resistance to heat and chemicals. This selection not only contributes to the overall performance of the vehicle but also aids in meeting regulatory standards concerning emissions and fuel efficiency.

In conclusion, the application of injection molding in the production of vehicle air inlet pipes exemplifies the intersection of technology and automotive design. As advancements in materials and molding techniques continue to evolve, the potential for innovation in vehicle components remains vast. Understanding this process is crucial for professionals within the automotive sector, as it directly influences both the functionality and efficiency of modern vehicles. By leveraging the capabilities of injection molding, manufacturers can ensure the production of high-quality, reliable air inlet pipes that support the performance demands of today’s automobiles.

Related news