Essential Insights into Automotive Injection Mold Tooling for Electronic Components

Automotive injection mold tooling involves creating molds that shape molten plastic into specific component designs.

2025-08-15

The automotive industry is undergoing rapid changes, particularly in the realm of electronic components. As a professional in this sector, mastering automotive injection mold tooling can significantly enhance your product development process. Injection molding is a pivotal manufacturing technique used to create complex and precise parts that are critical in automotive applications.

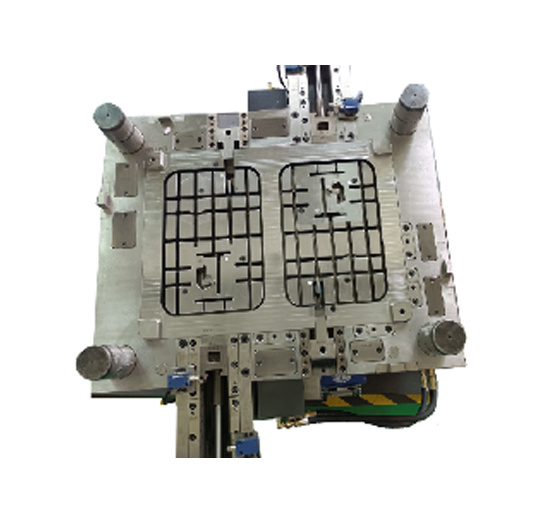

Automotive injection mold tooling involves creating molds that shape molten plastic into specific component designs. This process is vital for producing parts such as connectors, switches, and housings. One of the main benefits of injection molding is its ability to produce high volumes of parts with consistent quality. Understanding the nuances of this process can lead to significant improvements in production efficiency and cost management.

The selection of materials is a crucial aspect of automotive injection mold tooling. Engineers must consider factors such as thermal stability, durability, and compatibility with automotive standards. Commonly used materials include polypropylene, polycarbonate, and ABS, each offering unique properties suited for different applications. It’s essential to work closely with suppliers to ensure that the materials meet the stringent requirements of the automotive industry, particularly concerning safety and environmental regulations.

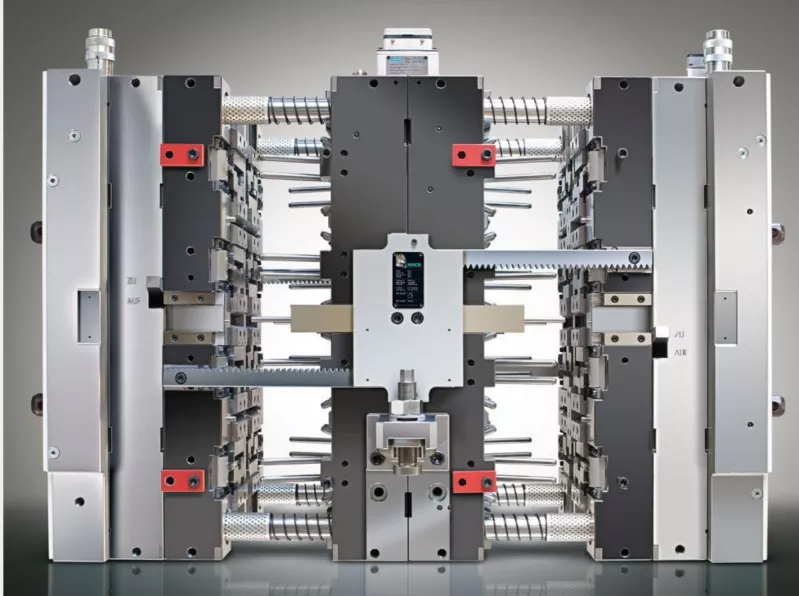

Moreover, the design of the mold itself plays a significant role in the quality of the final product. Engineers need to account for features such as draft angles, wall thickness, and gate locations to ensure optimal flow and cooling of the material. Utilizing advanced simulation software can aid in visualizing how the molten material will behave within the mold, thereby reducing the likelihood of defects and minimizing production time.

Collaboration with experienced mold makers is another critical factor in successful automotive injection mold tooling. Establishing a strong partnership can provide access to cutting-edge technologies and insights into best practices. In addition, ongoing communication throughout the design and production phases can help mitigate potential issues before they arise.

As the automotive sector continues to evolve with the incorporation of advanced electronics, staying informed about the latest trends and technologies in injection mold tooling is imperative. Investing in training and development for your team can foster innovation and improve overall product quality.

In conclusion, automotive injection mold tooling is an essential area of focus for professionals in the automotive electronic components industry. By understanding the materials, design considerations, and collaborative practices, you can enhance your manufacturing processes and contribute to the advancement of automotive technologies. Embrace the opportunities that effective tooling presents to stay competitive in this dynamic field.

Related news