Understanding Auto Part Molding with Stack Molds: Key Insights for Professionals

One innovative technique utilized in this field is auto part molding with stack molds.

2025-08-25

In the automotive industry, the production of electronic components and parts requires precision and efficiency. One innovative technique utilized in this field is auto part molding with stack molds. This method is particularly effective for creating complex shapes and designs needed for various automotive electronic and electrical components.

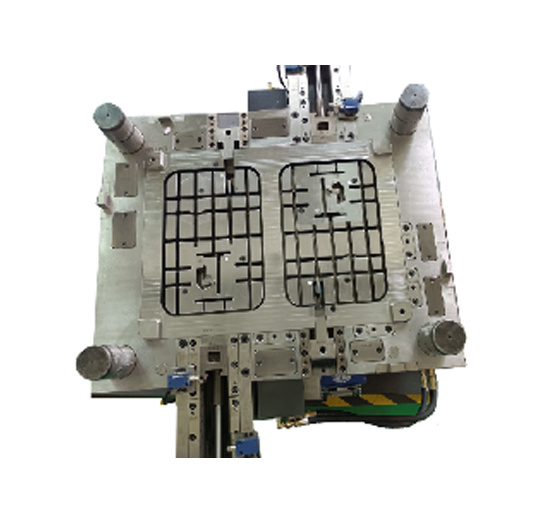

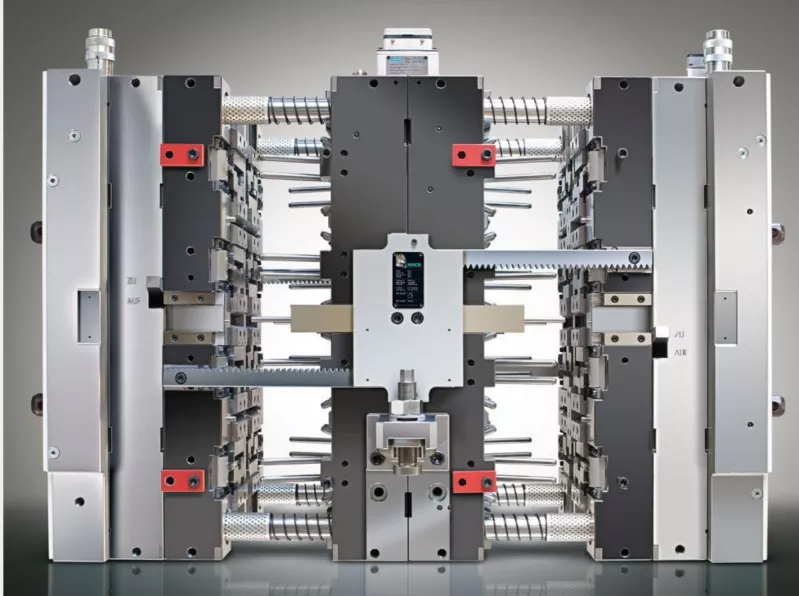

Stack molds are designed to maximize production efficiency by allowing multiple layers of parts to be molded simultaneously. This technique not only accelerates the production process but also optimizes material usage, resulting in reduced waste. As manufacturers strive to meet increasing demand while maintaining high-quality standards, stack molding presents a viable solution.

One of the primary advantages of using stack molds is the ability to produce two or more parts in a single cycle. This is particularly beneficial for components that require identical or similar geometries, such as connectors and housings used in automotive electronics. The concurrent molding of multiple parts reduces cycle times, allowing manufacturers to increase overall output without compromising on quality.

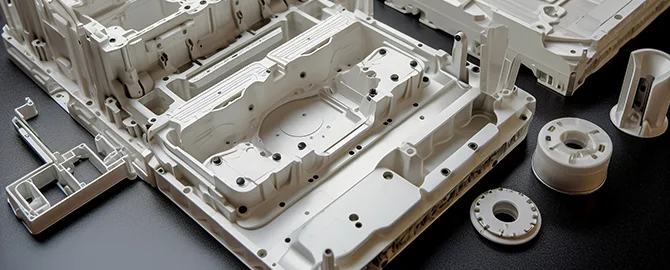

Moreover, stack molds facilitate intricate designs and features that are often challenging to achieve with traditional single-cavity molds. This capability is essential for the automotive industry, where components often need to accommodate specific functionalities, such as connectors or mounting features. The ability to mold complex shapes can lead to enhanced performance and reliability of electronic components, which are critical in modern vehicles.

Another point of consideration is the cost-effectiveness of stack molding. While the initial investment in stack molds may be higher compared to traditional molds, the long-term savings gained from reduced cycle times and increased part production can lead to significant cost reductions. In a competitive market, these advantages can give manufacturers a substantial edge.

In addition, stack molding can enhance the integration of different materials within a single part. This is particularly relevant in the automotive electronics sector, where components may require various materials for different functionalities, such as heat resistance or electrical conductivity. The ability to combine materials can lead to innovative product designs and improved performance characteristics.

In summary, auto part molding with stack molds represents a significant advancement in the production techniques available to the automotive and electronics industries. By leveraging the efficiency, cost-effectiveness, and design flexibility offered by stack molds, manufacturers can better meet the evolving demands of the automotive market. Understanding these advantages is crucial for professionals in the field as they navigate the complexities of modern automotive component production.

Related news