Unlocking Efficiency: The Role of Stack Molds in Auto Part Molding

In the rapidly evolving automotive industry, the quest for efficiency, quality, and cost-effectiveness remains paramount. A pivotal innovation in the realm of manufacturing is the development of stack molds.

2025-08-02

1. Introduction to Stack Molds in Auto Part Molding

In the rapidly evolving automotive industry, the quest for efficiency, quality, and cost-effectiveness remains paramount. A pivotal innovation in the realm of manufacturing is the development of stack molds. These advanced tools play a crucial role in the production of auto parts, enabling manufacturers to optimize their processes while maintaining high standards. In this article, we will delve into the auto part molding with stack molds, their advantages, types, and more, ultimately demonstrating their indispensable role in auto part molding.

2. What Are Stack Molds?

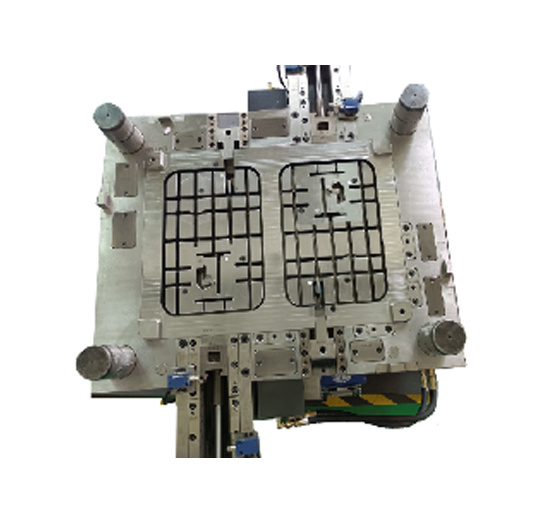

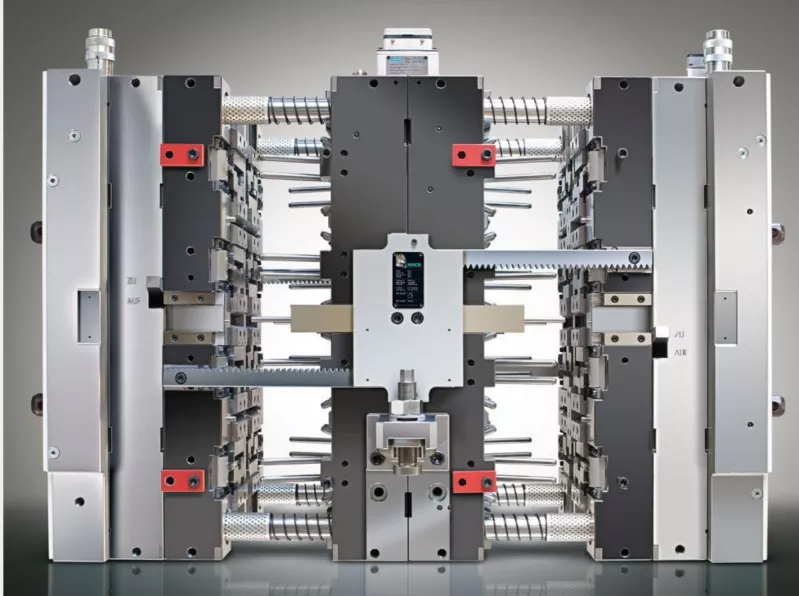

Stack molds are specialized injection molds designed to produce multiple parts simultaneously. Unlike traditional molds, which operate on a single plane, stack molds feature two or more stacked mold cavities that allow for simultaneous molding of multiple components. This innovative design not only maximizes the use of machine time but also enhances production rates, making them particularly beneficial in high-volume manufacturing settings.

3. Benefits of Using Stack Molds in Auto Part Manufacturing

The adoption of stack molds in auto part manufacturing brings forth a myriad of advantages that significantly impact productivity and operational efficiency.

3.1 Increased Production Efficiency

One of the most notable benefits of stack molds is their ability to enhance production efficiency. By enabling the simultaneous molding of multiple parts, these molds reduce cycle times and increase overall output. Manufacturers can produce more parts in less time, ultimately meeting market demands with greater agility.

3.2 Cost Reduction

Stack molds contribute to cost reduction in several ways. Firstly, the efficient use of materials reduces waste, as manufacturers can create multiple parts from a single batch of raw materials. Secondly, the decreased cycle times lead to lower labor costs, as machines require less operational time. Ultimately, the combination of these factors results in enhanced profitability for manufacturers.

3.3 Enhanced Product Quality

Quality is a non-negotiable aspect of auto part manufacturing. Stack molds facilitate uniformity in production, ensuring that each molded part maintains consistent dimensions and quality. The precision offered by stack molds minimizes defects, enhancing the reliability of the components produced.

4. Types of Stack Molds

Understanding the different types of stack molds is essential for manufacturers looking to implement these tools effectively. Each type offers unique advantages suited to various manufacturing needs.

4.1 Two-Level Stack Molds

Two-level stack molds are among the most common types used in the automotive industry. They consist of two stacked mold halves, allowing for the production of two parts simultaneously. This design is versatile and can be customized to accommodate various part shapes and sizes.

4.2 Multi-Level Stack Molds

For manufacturers dealing with high-volume production, multi-level stack molds offer an even greater advantage. These molds can have three or more levels, allowing for the simultaneous production of multiple parts in a single cycle. While the initial investment may be higher, the long-term benefits in terms of efficiency and cost savings are substantial.

4.3 Custom Stack Molds

Custom stack molds are designed to meet specific production requirements. Manufacturers can collaborate with mold designers to create molds tailored to their unique parts, optimizing the production process further.

5. The Manufacturing Process of Stack Molds

The manufacturing process of stack molds involves several critical steps, from design to production and testing. Understanding this process is essential for manufacturers seeking to implement stack mold technology effectively.

1. Design and Engineering: The first step involves designing the mold using CAD software. Engineers must consider factors like part size, shape, and desired production rates.

2. Material Selection: Choosing the right materials for the mold is crucial. High-quality steel or aluminum is often used for their durability and resistance to wear.

3. Machining: Once the design is finalized, the mold components are machined to their precise specifications. This step often involves CNC machining to achieve high levels of accuracy.

4. Assembly: After machining, the various components of the stack mold are assembled. This step requires careful attention to detail to ensure proper alignment and functionality.

5. Testing and Validation: Before full-scale production, the mold undergoes rigorous testing to ensure it operates as intended. This phase is vital for identifying any potential issues that could affect production quality.

6. Key Considerations When Choosing Stack Molds

Selecting the right stack molds for auto part production involves several critical considerations:

- Production Volume: Consider the expected production volume to determine the appropriate type of stack mold.

- Part Complexity: Evaluate the complexity of the parts being produced, as this will influence mold design.

- Budget Constraints: Assess the budget for mold production and maintenance, as more advanced molds may involve higher initial costs.

7. Real-World Applications of Stack Molds in Automotive Manufacturing

Stack molds are employed in various applications within the automotive sector, each showcasing their versatility:

- Interior Components: Stack molds are frequently used to produce interior components like dashboard panels and console covers, where precision and durability are paramount.

- Lighting Components: The production of automotive lighting components, such as headlights and taillights, benefits from stack molds due to their ability to create intricate designs with uniform quality.

- Electrical Housings: Stack molds are ideal for manufacturing electrical housings, where precise dimensions and reliable performance are critical.

8. FAQs About Stack Molds and Auto Part Molding

Q1: What is the primary advantage of using stack molds over traditional molds?

A1: The primary advantage is the ability to produce multiple parts simultaneously, leading to increased production efficiency and cost savings.

Q2: How do stack molds improve product quality?

A2: Stack molds ensure uniformity in production, minimizing defects and maintaining consistent dimensions across all parts.

Q3: Are stack molds suitable for low-volume production?

A3: While stack molds excel in high-volume production, they can also be customized for lower volumes, though the benefits may not be as pronounced.

Q4: What materials are commonly used in stack mold production?

A4: High-quality steel and aluminum are the most commonly used materials due to their durability and resistance to wear.

Q5: How long does it typically take to manufacture a stack mold?

A5: The time required can vary based on complexity and design, but it generally ranges from a few weeks to several months.

9. Conclusion

The implementation of stack molds in the automotive industry represents a significant advancement in manufacturing efficiency. By enabling the simultaneous production of multiple parts, stack molds not only boost productivity but also reduce costs and enhance product quality. As the automotive sector continues to evolve, embracing technologies like stack molds will be essential for manufacturers looking to maintain competitiveness in a rapidly changing market. Ultimately, stack molds are not just a tool but a transformative solution that paves the way for innovation and efficiency in auto part molding.

Related news