Injection Molding: Crafting the Future of Peugeot Component Manufacturing

In the automotive industry, the need for high-quality, durable, and precise components has never been more critical. Injection molding has emerged as a leading manufacturing technique that meets these demands, especially for brands like Peugeot.

2025-07-30

1. Introduction to Injection Molding in Automotive Manufacturing

In the automotive industry, the need for high-quality, durable, and precise components has never been more critical. Injection molding has emerged as a leading manufacturing technique that meets these demands, especially for brands like Peugeot. This article explores how injection molding is shaping the future of component manufacturing for Peugeot vehicles, bringing innovations in production efficiency, cost savings, and product quality.

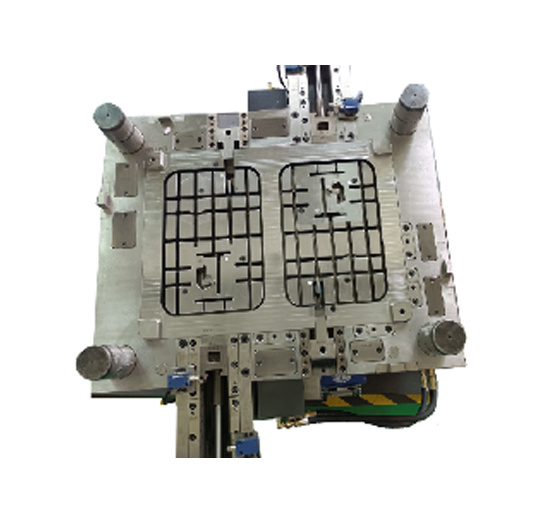

2. Understanding Injection Molding: A Key Manufacturing Process

Injection molding is a manufacturing process that involves injecting molten material into a mold to create parts and products. This method is highly regarded for its ability to produce complex shapes with high accuracy and repeatability. Common materials used in injection molding include thermoplastics, thermosetting plastics, and elastomers.

The process typically involves the following steps:

1. Material Preparation: Raw plastic pellets are heated until they melt.

2. Injection: The molten material is injected into a mold cavity under high pressure.

3. Cooling: The material cools and solidifies inside the mold.

4. Ejection: The finished part is ejected from the mold once it has cooled sufficiently.

3. Benefits of Injection Molding for Peugeot Components

The adoption of injection molding at Peugeot offers numerous advantages, including:

3.1 Cost Efficiency

Injection molding is highly efficient, allowing Peugeot to manufacture large quantities of components at a lower cost per unit. This is particularly beneficial in high-volume production runs.

3.2 Precision and Quality

The precision of injection molding ensures that components meet stringent quality standards. This is crucial for automotive parts, where even slight deviations can lead to performance issues.

3.3 Design Flexibility

Injection molding allows for significant design flexibility, enabling Peugeot to create complex geometries that would be challenging or impossible with traditional manufacturing methods.

3.4 Reduced Waste

The process generates minimal waste, making it a more environmentally friendly option compared to other manufacturing techniques.

4. Peugeot and Injection Molding: A Strategic Partnership

Peugeot has embraced injection molding as a core part of its manufacturing strategy. By investing in state-of-the-art molding technologies and facilities, the company has positioned itself to lead in innovation and quality. The collaboration with expert injection molding partners has enhanced their ability to produce components that meet evolving market demands and regulatory standards.

5. Technological Advancements in Injection Molding

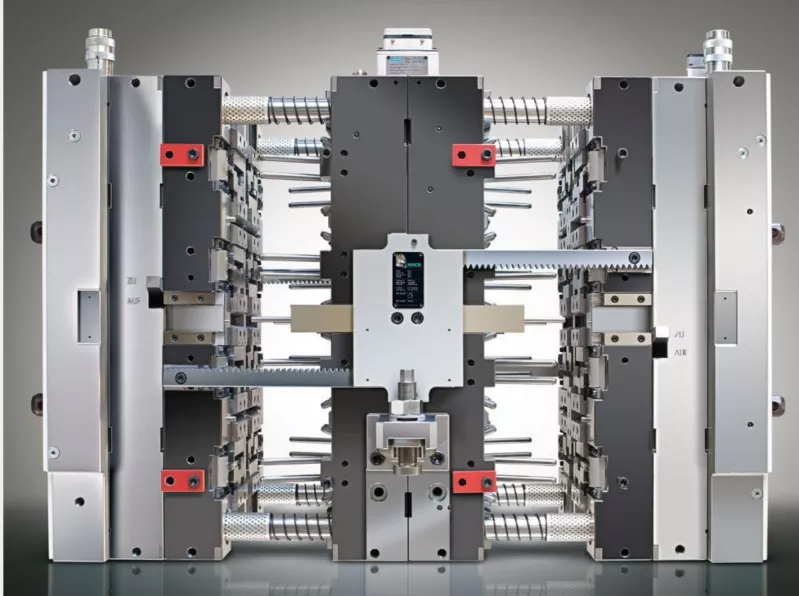

The injection molding landscape is continuously evolving, driven by technological advancements that improve efficiency and capability. Key innovations include:

5.1 Automation and Robotics

Incorporating automation and robotics into injection molding processes has significantly increased production rates while reducing labor costs and human error.

5.2 3D Printing Integration

The integration of 3D printing technologies allows for rapid prototyping and the creation of intricate mold designs, streamlining the design process for new components.

5.3 Advanced Materials

The development of new, high-performance materials expands the possibilities for injection molded components, leading to enhanced performance and durability.

6. Sustainability in Injection Molding Processes

As environmental concerns grow, Peugeot is committed to sustainable manufacturing practices. Injection molding can play a critical role in this effort:

6.1 Use of Recycled Materials

Many modern injection molding processes incorporate recycled materials, reducing reliance on virgin resources and minimizing environmental impact.

6.2 Energy-Efficient Equipment

Investing in energy-efficient machines and technologies lowers the carbon footprint of the manufacturing process.

6.3 Waste Reduction Strategies

Implementing waste reduction strategies during the molding process further enhances sustainability, aligning with Peugeot's commitment to eco-friendly practices.

7. Case Studies: Successful Injection Molding Applications at Peugeot

Several successful applications of injection molding within Peugeot serve as excellent examples of its benefits:

7.1 Manufacturing of Dashboard Components

Peugeot utilizes injection molding to produce dashboard components that require precision and durability. The process allows for aesthetic designs while maintaining functionality and safety.

7.2 Production of Lighting Units

Injection molding is essential in the production of lighting units, where clarity and robustness are crucial. The ability to create complex shapes means that Peugeot can innovate in design while maintaining performance.

7.3 Creating Engine Covers

Using injection molding for engine covers enables Peugeot to produce lightweight yet strong components that contribute to overall vehicle efficiency.

8. Future Trends in Injection Molding for the Automotive Industry

The future of injection molding in automotive manufacturing is ripe with possibilities. Trends to watch include:

8.1 Increased Use of Smart Manufacturing

The implementation of IoT and AI technologies in injection molding processes will lead to smarter, more connected manufacturing environments.

8.2 Greater Customization Capabilities

Future advancements will likely allow for more customized components, catering to specific consumer needs and preferences.

8.3 Enhanced Circular Economy Practices

As the automotive industry shifts towards a circular economy, injection molding will play a vital role in facilitating recycling and reuse of materials, further promoting sustainability.

9. Frequently Asked Questions About Injection Molding

9.1 What materials are commonly used in injection molding?

Common materials include thermoplastics like ABS, polycarbonate, and nylon, as well as thermosetting plastics.

9.2 How does injection molding compare to other manufacturing processes?

Injection molding offers superior precision, lower waste, and faster production times compared to processes like CNC machining or casting.

9.3 What industries benefit from injection molding?

Besides automotive, industries such as consumer electronics, medical devices, and packaging utilize injection molding for component manufacturing.

9.4 How does the injection molding process ensure quality control?

Quality control is maintained through rigorous testing, precise machine settings, and adherence to industry standards during production.

9.5 What are the typical lead times for injection molded parts?

Lead times vary based on design complexity and production volume, but they typically range from a few weeks to a few months.

10. Conclusion

Injection molding is not just a manufacturing technique; it is a transformative process that is shaping the future of component manufacturing for Peugeot. By leveraging its benefits—cost efficiency, precision, design flexibility, and sustainability—Peugeot is poised to meet the challenges of the modern automotive industry. As technology continues to advance, the potential for injection molding in creating innovative, high-quality automotive components will only grow. Embracing these changes will ensure that Peugeot remains at the forefront of automotive manufacturing excellence.

Related news