Revolutionize Your Car Interior with Two Shot Injection Molding

Two shot injection molding is an advanced manufacturing process that allows for the creation of complex parts by injecting two different materials into a single mold. This technique is particularly beneficial in the automotive industry, where it is used to produce high-quality, aesthetically pleasing, and functional components for car interiors.

2025-07-21

What is Two Shot Injection Molding?

Two shot injection molding is an advanced manufacturing process that allows for the creation of complex parts by injecting two different materials into a single mold. This technique is particularly beneficial in the automotive industry, where it is used to produce high-quality, aesthetically pleasing, and functional components for car interiors. The unique aspect of two shot molding lies in its ability to combine materials, such as rigid plastics and elastomers, to create parts that can fulfill multiple functions and achieve superior performance. With this method, manufacturers can craft components that are not only visually appealing but also durable and resistant to wear and tear.

Benefits of Two Shot Injection Molding in Automotive Design

The adoption of two shot injection molding in automotive design offers numerous advantages:

Enhanced Aesthetics and Customization

Two shot injection molding enables manufacturers to produce intricate designs with varied textures and colors. This flexibility allows for greater customization options, enabling car manufacturers to cater to diverse consumer preferences and enhance the overall visual appeal of the vehicle interior.

Improved Durability and Functionality

By combining different materials, two shot molding creates components that can better withstand the rigors of daily use. For instance, parts can be designed to have a hard outer shell with a soft inner layer, providing both durability and comfort, which is crucial for car interiors.

Reduction in Assembly Time and Costs

Traditionally, multiple parts would require assembly after individual production. Two shot injection molding simplifies this process by producing a single part that fulfills multiple functions, thereby reducing assembly time and associated labor costs.

Efficiency in Material Usage

This molding process minimizes waste by utilizing materials more efficiently. Manufacturers can optimize the use of both materials, leading to cost savings and a lower environmental impact.

The Process of Two Shot Injection Molding

The process of two shot injection molding involves several key stages:

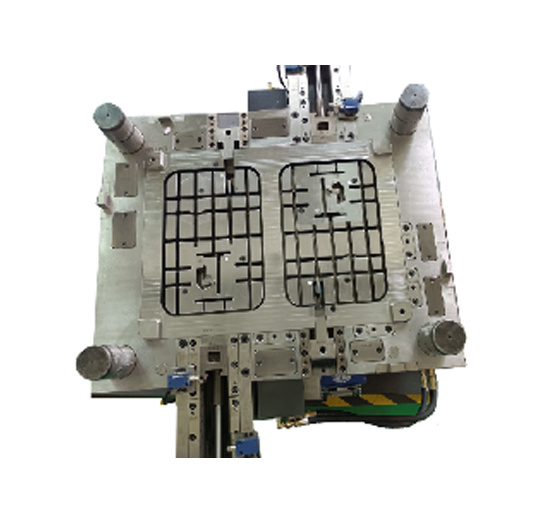

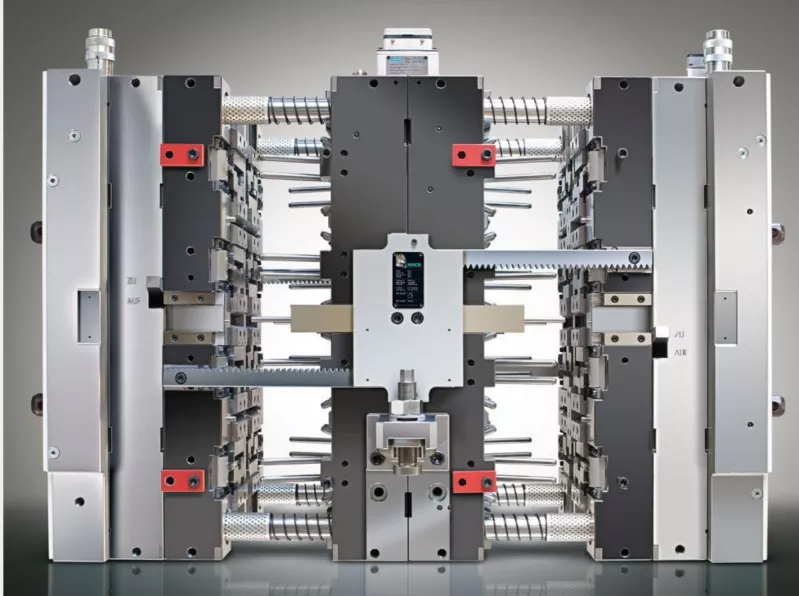

1. Mold Design

The first step is designing the mold that will shape the final product. This mold must accommodate two different materials and their respective injection processes.

2. Material Selection

Choosing the right materials is critical. Factors such as flexibility, hardness, and color must be considered to ensure the final product meets design specifications and performance standards.

3. Injection Process

In the first injection, the first material is injected into the mold, filling the designated areas. After this material has cooled slightly, the second material is injected into the same mold, adhering to the first material and creating a cohesive single part.

4. Cooling and Ejection

Once both materials have cooled and solidified, the final part is ejected from the mold. Quality checks are then performed to ensure the integrity and specifications of the part.

Applications of Two Shot Injection Molding in Car Interiors

Two shot injection molding has numerous applications in automotive interiors:

Dashboard Components

The dashboard is a focal point of any vehicle's interior. Using two shot molding, manufacturers can create dashboards that are not only visually striking but also functional, integrating soft-touch surfaces with hard plastic components.

Console Parts

Center consoles often feature a combination of hard and soft materials. Two shot molding allows for the production of console parts that are both durable and comfortable to touch, improving user experience.

Door Panels

Door panels benefit from this process as manufacturers can design panels that have varying textures and colors while ensuring they are robust enough to withstand frequent use.

Seating Components

Two shot molding can be used in the production of seating components that require both rigidity and comfort, enhancing overall passenger experience in the vehicle.

Designing with Two Shot Injection Molding: Key Considerations

When designing components with two shot molding, several factors must be taken into account:

Material Compatibility

The materials used must be compatible to ensure proper adhesion and performance. This requires a deep understanding of the properties of each material and how they interact during the molding process.

Design Complexity

While two shot molding allows for intricate designs, overly complex geometries can lead to production challenges. Designers should strike a balance between aesthetics and manufacturability.

Cost Considerations

While two shot molding can reduce assembly costs, the initial investment in molds and machinery can be significant. A thorough cost-benefit analysis is essential when considering this manufacturing method.

Sustainability and Eco-Friendliness of Two Shot Injection Molding

In today's environmentally conscious market, the sustainability of manufacturing processes is paramount. Two shot injection molding offers several eco-friendly advantages:

Material Efficiency

Using materials efficiently reduces waste, as excess material can often be minimized or recycled. This aligns with the growing demand for sustainable manufacturing practices in the automotive industry.

Energy Efficiency

The two shot molding process can be more energy-efficient than traditional methods, as it reduces the need for multiple production stages and associated energy consumption.

Recyclable Materials

Many materials used in two shot molding can be selected for their recyclability, contributing to a circular economy and reducing the environmental footprint of automotive production.

Future Trends in Automotive Interior Design

The automotive industry is constantly evolving, and two shot injection molding is at the forefront of several key trends:

Smart Interiors

As vehicles become more technologically advanced, the demand for smart interior components is rising. Two shot molding enables the integration of sensors and electronics directly into design components.

Personalization

Consumers are increasingly seeking personalized experiences in their vehicles. Two shot molding allows manufacturers to create customizable components, enhancing user engagement and satisfaction.

Lightweight Materials

Reducing vehicle weight is crucial for improving fuel efficiency. Two shot molding can facilitate the use of lightweight materials that do not compromise on strength or durability.

FAQs About Two Shot Injection Molding

1. What materials are typically used in two shot injection molding?

Two shot injection molding commonly uses thermoplastics like ABS, polycarbonate, and TPU. These materials offer durability and flexibility, essential for automotive components.

2. Can two shot injection molding be used for all types of automotive parts?

While two shot molding is versatile, it is best suited for parts that require multiple materials or complex shapes. Components such as dashboards, consoles, and door panels are ideal candidates.

3. How does two shot injection molding compare to traditional injection molding?

Two shot molding allows for the creation of multi-material parts in a single process, reducing assembly time and costs, whereas traditional molding typically requires separate processes for each material.

4. Is two shot molding environmentally friendly?

Yes, two shot molding can be more sustainable as it minimizes waste and energy use. Additionally, recyclable materials can often be used in the process.

5. What are the cost implications of using two shot injection molding?

While the initial investment in machinery and molds can be higher, the long-term savings from reduced assembly costs and material efficiencies often outweigh these initial expenses.

Conclusion

Two shot injection molding is revolutionizing the automotive industry, particularly in the realm of car interiors. Its ability to create aesthetically pleasing, durable, and multifunctional components addresses both consumer demands and industry challenges. As the market continues to evolve, the integration of this innovative manufacturing process will play a pivotal role in shaping the future of automotive design, offering enhanced customization, reduced environmental impact, and improved overall user experiences. By embracing two shot injection molding, manufacturers can not only meet but exceed the expectations of modern drivers, ensuring that car interiors are as sophisticated and functional as they are stylish.

Related news