Crafting Precision: The Role of Automotive Molds in Dashboard Pipe Production

Crafting Precision: The Role of Automotive Molds in Dashboard Pipe Production Table of Contents 1. Introduction: The Importance of Molds in Automotive Manufacturing 2. What Are Automotive Molds? 3. Types of Automotive Molds Used in Dashboard Pipe Production 3.1 Injection Molds 3.2 Blow Molds 3.3 Compression Molds 4. Materials Used in Automotive Molds 5. The Manufacturing Process of Dashb

2025-10-14

Crafting Precision: The Role of Automotive Molds in Dashboard Pipe Production

Table of Contents

1. Introduction: The Importance of Molds in Automotive Manufacturing

2. What Are Automotive Molds?

3. Types of Automotive Molds Used in Dashboard Pipe Production

3.1 Injection Molds

3.2 Blow Molds

3.3 Compression Molds

4. Materials Used in Automotive Molds

5. The Manufacturing Process of Dashboard Pipes

5.1 Design and Engineering of Dashboard Pipes

5.2 Mold Fabrication Techniques

6. Quality Control in Mold Production

7. Innovations in Automotive Mold Technology

8. Conclusion: The Future of Automotive Molds in Dashboard Pipe Production

9. FAQs

Introduction: The Importance of Molds in Automotive Manufacturing

In the rapidly evolving world of automotive manufacturing, precision is paramount. The production of dashboard pipes, which play a vital role in vehicle functionality and aesthetics, relies heavily on the expertise of automotive molds. These molds are not just tools; they are the foundation upon which quality automotive components are built. By understanding the importance of automotive molds in dashboard pipe production, manufacturers can ensure optimal performance, safety, and a seamless user experience.

What Are Automotive Molds?

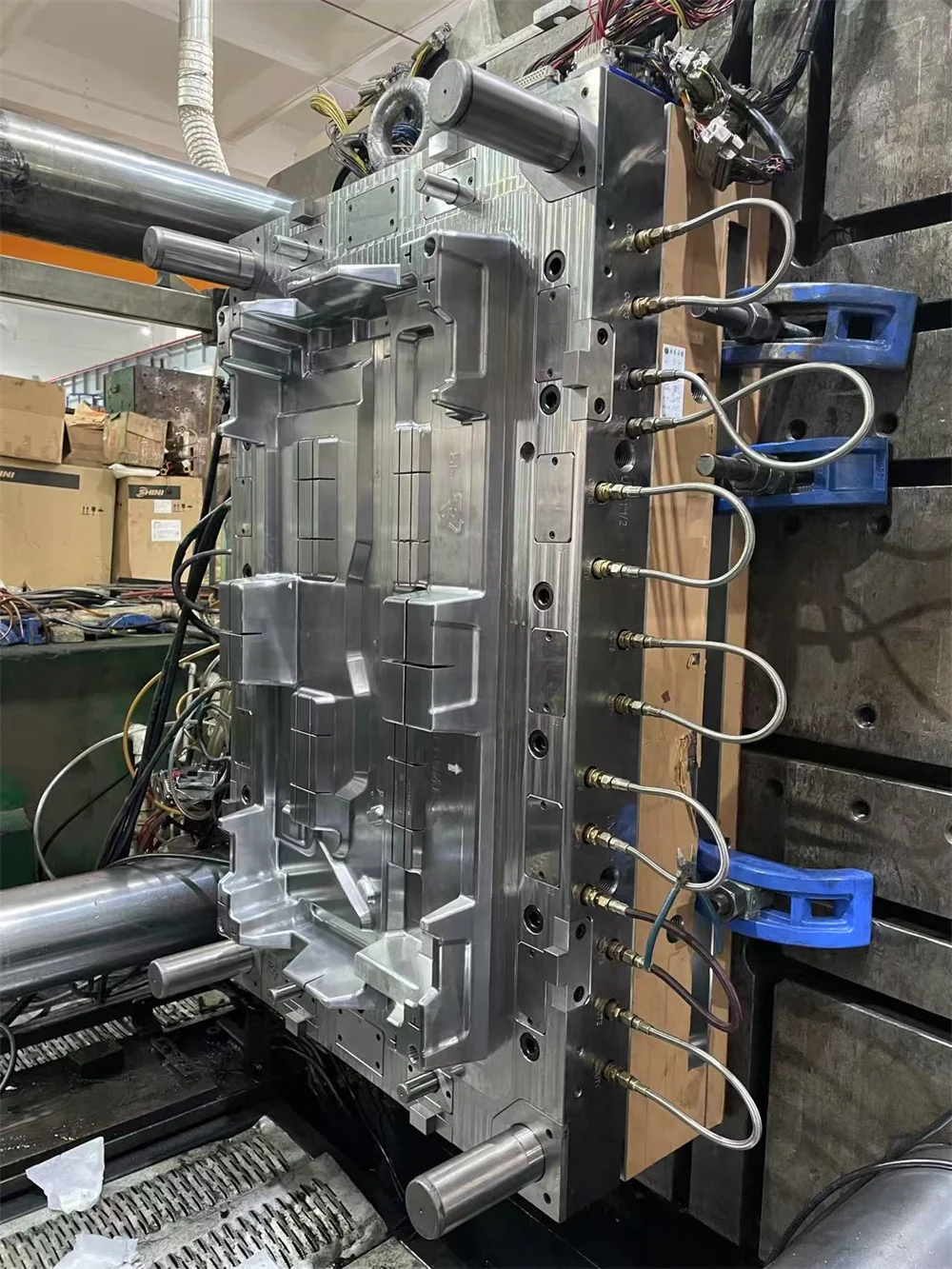

Automotive molds are specialized tools used to shape and form various components within vehicles, including dashboard pipes. They are crafted from durable materials to withstand the high pressures and temperatures involved in the molding processes. Automotive molds are integral in producing parts with precise dimensions, ensuring that each piece fits perfectly within the overall vehicle design.

Types of Automotive Molds Used in Dashboard Pipe Production

When it comes to producing dashboard pipes, various types of automotive molds are employed. Each type serves a specific purpose within the production process. Understanding these types can help manufacturers select the most suitable mold for their needs.

Injection Molds

Injection molding is one of the most common and effective methods used in automotive manufacturing. In this process, molten material is injected into a mold cavity, where it cools and solidifies into the desired shape. Injection molds are perfect for high-volume production and are renowned for their ability to create complex geometries with consistent quality.

Blow Molds

Blow molding is utilized for creating hollow parts, such as tubes and pipes. This method involves inflating heated plastic within a mold to form the desired shape. Blow molds are particularly valuable in dashboard pipe production, as they can efficiently produce lightweight and durable components.

Compression Molds

Compression molding involves placing a pre-measured amount of material into an open mold cavity, which is then closed to shape the component. This method is beneficial for creating larger parts and allows for the use of various materials, including thermosetting plastics. Compression molds offer flexibility in design and material choices.

Materials Used in Automotive Molds

The choice of materials in automotive mold production is crucial for ensuring durability, precision, and performance. Common materials include:

- **Steel:** Known for its strength and longevity, steel is often used for injection molds.

- **Aluminum:** Lightweight and cost-effective, aluminum molds are suitable for lower-volume production runs.

- **Beryllium Copper:** This material combines excellent thermal conductivity with strength, making it ideal for intricate mold designs.

- **Polymer:** Used in some applications, polymers offer flexibility and ease of manufacturing.

Each of these materials has unique properties that make them suitable for different types of molds and production processes.

The Manufacturing Process of Dashboard Pipes

The production of dashboard pipes involves several stages, each critical to the final product's quality and precision. Understanding this process allows manufacturers to optimize their operations and deliver superior components.

Design and Engineering of Dashboard Pipes

The first step in manufacturing dashboard pipes is the design and engineering phase. This process involves:

- **Concept Development:** Engineers develop initial concepts based on functional requirements and aesthetic considerations.

- **CAD Modeling:** Computer-aided design (CAD) software is used to create detailed 3D models of the dashboard pipes.

- **Prototyping:** Initial prototypes are produced to test the design and make necessary adjustments before moving into full-scale production.

This phase is vital for ensuring that the dashboard pipes meet both functional and design specifications.

Mold Fabrication Techniques

Once the design is finalized, the next phase is mold fabrication, which includes:

- **CNC Machining:** Computer numerical control (CNC) machines are used to create precise mold components.

- **Electro-Discharge Machining (EDM):** This technique is often employed for intricate details that cannot be achieved with standard machining methods.

- **Assembly:** The various components of the mold are assembled to form a complete unit, ready for production.

These advanced fabrication techniques ensure that molds are made with the utmost precision, resulting in high-quality dashboard pipes.

Quality Control in Mold Production

Quality control is an essential aspect of automotive mold production. Rigorous testing and inspection processes are implemented to ensure that molds meet stringent industry standards. Quality control measures include:

- **Dimensional Inspection:** Measurements are taken to ensure that molds conform to design specifications.

- **Material Testing:** The materials used in mold production are tested for strength, durability, and other relevant properties.

- **Performance Testing:** Molds are subjected to operational tests to evaluate their effectiveness in producing dashboard pipes.

These stringent quality control measures help manufacturers minimize defects and ensure reliable product performance.

Innovations in Automotive Mold Technology

As the automotive industry continues to evolve, so does mold technology. Recent innovations include:

- **3D Printing:** Additive manufacturing allows for rapid prototyping and the production of complex mold designs that traditional methods cannot achieve.

- **Smart Molds:** Incorporating sensors into molds can provide real-time data on temperature, pressure, and other variables during the production process, enabling better control and optimization.

- **Sustainable Materials:** The use of biodegradable and recyclable materials in mold production is gaining traction, aligning with the industry's growing focus on sustainability.

These advancements are helping manufacturers improve efficiency, reduce costs, and enhance the quality of automotive parts.

Conclusion: The Future of Automotive Molds in Dashboard Pipe Production

In conclusion, automotive molds play a crucial role in the production of dashboard pipes, impacting not only the quality and precision of individual components but also the overall performance and aesthetic appeal of vehicles. As technology continues to advance, manufacturers must stay abreast of the latest developments in mold design and fabrication to remain competitive in the ever-evolving automotive landscape. The marriage of innovative technologies with traditional methods will pave the way for more efficient, sustainable, and high-quality automotive manufacturing.

FAQs

1. What materials are commonly used in the production of automotive molds?

Automotive molds are typically made from materials like steel, aluminum, beryllium copper, and polymers, each offering unique properties suited for different molding processes.

2. How does injection molding compare to blow molding in automotive applications?

Injection molding is ideal for creating complex geometries and is used for solid parts, while blow molding is better for producing hollow components like dashboard pipes.

3. What steps are involved in the quality control process for automotive molds?

Quality control includes dimensional inspection, material testing, and performance testing to ensure molds meet industry standards and specifications.

4. How can 3D printing technology improve mold production?

3D printing allows for rapid prototyping and the creation of intricate mold designs that are difficult to achieve with traditional machining methods.

5. Why is sustainability important in automotive mold production?

Sustainability is important as the automotive industry seeks to reduce its environmental impact. Using biodegradable and recyclable materials helps manufacturers align with eco-friendly practices.

By focusing on precision and quality, manufacturers can effectively harness the capabilities of automotive molds to produce superior dashboard pipes and components, leading to enhanced vehicle performance and customer satisfaction.

Related news