Transforming Your Auto Dashboard: The Role of Injection Molding in Modern Vehicle Design

Transforming Your Auto Dashboard: The Role of Injection Molding in Modern Vehicle Design Table of Contents 1. Introduction to Injection Molding in Automotive Design 2. Understanding Injection Molding and Its Benefits 3. The Importance of Auto Dashboards in Vehicle Design 4. Materials Used in Injection Molding for Auto Dashboards 5. The Process of Injection Molding: A Step-by-S

2025-09-28

Transforming Your Auto Dashboard: The Role of Injection Molding in Modern Vehicle Design

Table of Contents

- 1. Introduction to Injection Molding in Automotive Design

- 2. Understanding Injection Molding and Its Benefits

- 3. The Importance of Auto Dashboards in Vehicle Design

- 4. Materials Used in Injection Molding for Auto Dashboards

- 5. The Process of Injection Molding: A Step-by-Step Guide

- 6. Design Considerations for Injection Molded Auto Dashboards

- 7. Sustainability and Innovation in Injection Molding

- 8. Future Trends in Injection Molding for Automotive Applications

- 9. FAQs About Injection Molding in Automotive Design

- 10. Conclusion: The Future of Auto Dashboards

1. Introduction to Injection Molding in Automotive Design

The automotive industry is undergoing significant transformations fueled by technological advancements and shifts in consumer expectations. One of the most impactful processes in this evolution is **injection molding**, which plays a vital role in creating high-quality, durable, and aesthetically pleasing auto dashboards. In this article, we will delve into the intricacies of injection molding, its benefits for auto dashboards, and the future of automotive design.

2. Understanding Injection Molding and Its Benefits

Injection molding is a manufacturing process that involves injecting molten material, typically plastic, into a mold to create specific shapes and components. This technique offers numerous benefits that are particularly advantageous in automotive applications:

2.1 Cost-Effectiveness

The injection molding process is economical, especially for large-scale production. Once a mold is created, the cost per part decreases significantly as production scales up, making it ideal for the automotive industry.

2.2 Precision and Consistency

Injection molding allows for high precision and consistency in manufacturing. This is crucial for auto dashboards, where components must fit together seamlessly to ensure functionality and safety.

2.3 Versatility of Materials

A wide array of materials can be used in injection molding, from engineering plastics to elastomers. This versatility allows designers to choose materials that best suit the vehicle's aesthetic and functional requirements.

3. The Importance of Auto Dashboards in Vehicle Design

The auto dashboard is more than just an aesthetic element; it serves as the control center for the driver, housing essential instruments and controls. A well-designed dashboard contributes to:

3.1 Driver Experience

A thoughtfully designed dashboard enhances the driver’s experience by providing intuitive access to controls and information through layout and ergonomics.

3.2 Safety Features

Dashboards often incorporate safety features, such as airbag deployment mechanisms and impact-absorbing materials, which protect passengers in the event of a collision.

3.3 Aesthetic Appeal

The visual design of a dashboard plays a major role in the vehicle's overall appeal, influencing consumer purchasing decisions and brand loyalty.

4. Materials Used in Injection Molding for Auto Dashboards

Choosing the right materials for injection molding is crucial for the functionality and aesthetics of auto dashboards. Common materials include:

4.1 Acrylonitrile Butadiene Styrene (ABS)

ABS is widely used due to its strength, impact resistance, and ability to be molded into complex shapes. It is also easily painted and finished for aesthetic appeal.

4.2 Polycarbonate (PC)

Polycarbonate is known for its durability and transparency, making it an excellent choice for dashboard displays and covers.

4.3 Polypropylene (PP)

PP is lightweight, flexible, and resistant to chemical exposure, making it suitable for components that require durability against wear and tear.

5. The Process of Injection Molding: A Step-by-Step Guide

Understanding the injection molding process can provide insights into how auto dashboards are manufactured:

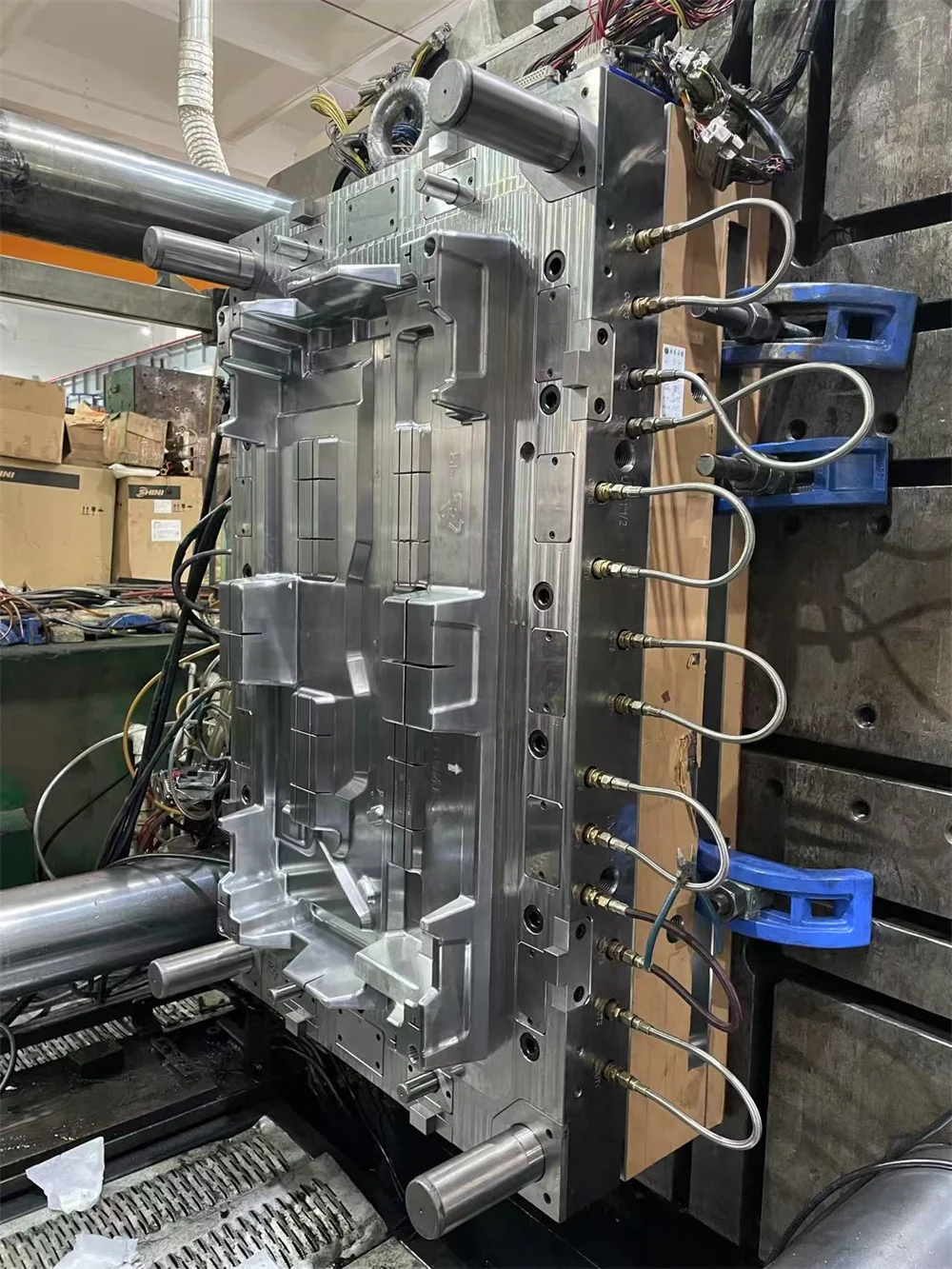

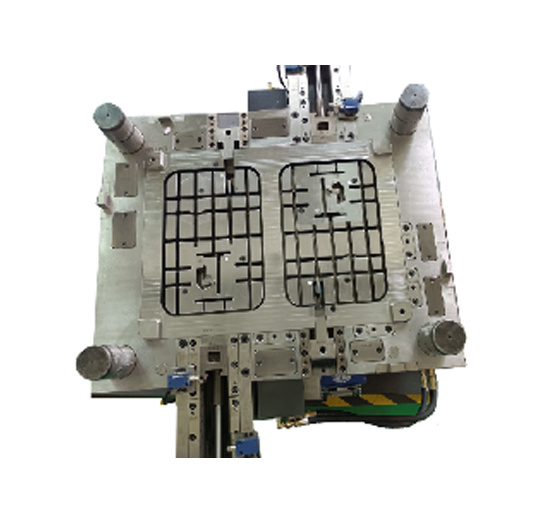

5.1 Mold Design

The first step is designing the mold, which is a critical component of the process. Designers must consider the final part's geometry, material flow, and cooling mechanisms.

5.2 Material Preparation

The raw material is prepared by heating it until it reaches a molten state, ready for injection.

5.3 Injection

The molten material is injected into the mold under high pressure, filling the cavity and taking the shape of the mold.

5.4 Cooling and Ejection

Once the material cools and solidifies, the mold opens, and the finished part is ejected.

5.5 Finishing Processes

Additional finishing processes, such as trimming, painting, or assembly, may follow to achieve the desired aesthetic and functional quality.

6. Design Considerations for Injection Molded Auto Dashboards

When designing auto dashboards for injection molding, several key considerations must be addressed:

6.1 Ergonomics

Dashboard layouts must be ergonomically sound, allowing drivers to access controls without distraction or discomfort.

6.2 Aesthetic Integration

Designs should integrate seamlessly with the vehicle's interior, reflecting the brand's style and enhancing the overall look.

6.3 Functionality and Safety

It is vital to ensure that the dashboard design accommodates all necessary functions while prioritizing safety features and regulations.

7. Sustainability and Innovation in Injection Molding

The automotive industry is increasingly focused on sustainability. Injection molding is evolving to support eco-friendly initiatives, including:

7.1 Use of Recycled Materials

Many manufacturers are turning to recycled plastics, which reduce waste and environmental impact while still maintaining quality.

7.2 Energy-Efficient Processes

Advancements in technology are leading to more energy-efficient injection molding machines, lowering the carbon footprint of the manufacturing process.

7.3 Bioplastics in Dashboard Production

The exploration of bioplastics presents new opportunities for sustainable dashboard materials that are both functional and environmentally friendly.

8. Future Trends in Injection Molding for Automotive Applications

As automotive technology continues to advance, several trends are shaping the future of injection molding in dashboard design:

8.1 Integration of Smart Technology

With the rise of smart vehicles, dashboards are becoming more sophisticated, integrating displays, touch interfaces, and voice control systems.

8.2 Customization Options

Consumer demand for personalized vehicles is driving manufacturers to offer customizable dashboard elements through injection molding.

8.3 Advanced Manufacturing Techniques

The adoption of advanced manufacturing technologies, such as 3D printing and hybrid molding processes, is revolutionizing how auto dashboards are designed and produced.

9. FAQs About Injection Molding in Automotive Design

9.1 What is injection molding?

Injection molding is a manufacturing process where molten material is injected into a mold to create specific shapes and components, widely used in automotive applications.

9.2 What materials are commonly used in injection molding for dashboards?

Common materials include ABS, polycarbonate, and polypropylene, each offering unique properties suitable for automotive applications.

9.3 How does the injection molding process work?

The process involves mold design, material preparation, injection, cooling, ejection, and finishing processes to create the final dashboard components.

9.4 What are the benefits of using injection molding for auto dashboards?

Benefits include cost-effectiveness, precision, consistency, and the ability to use a variety of materials to achieve the desired look and functionality.

9.5 How is sustainability addressed in injection molding?

Sustainability is addressed through the use of recycled materials, energy-efficient processes, and the exploration of bioplastics for dashboard components.

10. Conclusion: The Future of Auto Dashboards

Injection molding is a transformative force in the automotive industry, particularly regarding the design and production of auto dashboards. This manufacturing process not only enhances functionality and aesthetic appeal but also contributes to sustainability efforts within the industry. As the automotive landscape continues to evolve, the role of injection molding will be paramount in shaping the vehicles of tomorrow, ensuring they meet the demands of consumers and the environment alike. By embracing innovation and sustainability, the future of auto dashboards is bright, paving the way for safer, smarter, and more environmentally friendly vehicles.

Related news