Understanding Automotive Mold Tools for Plastic Radiator Parts

In the automotive industry, mold tools play a pivotal role in the production of various components, particularly plastic radiator parts. These parts are essential for vehicle cooling systems, ensuring that engines operate at optimal temperatures. The design and manufacturing of automotive mold tools specifically for plastic radiator parts require a deep understanding of material properties, design

2025-09-24

In the automotive industry, mold tools play a pivotal role in the production of various components, particularly plastic radiator parts. These parts are essential for vehicle cooling systems, ensuring that engines operate at optimal temperatures. The design and manufacturing of automotive mold tools specifically for plastic radiator parts require a deep understanding of material properties, design intricacies, and the overall production process.

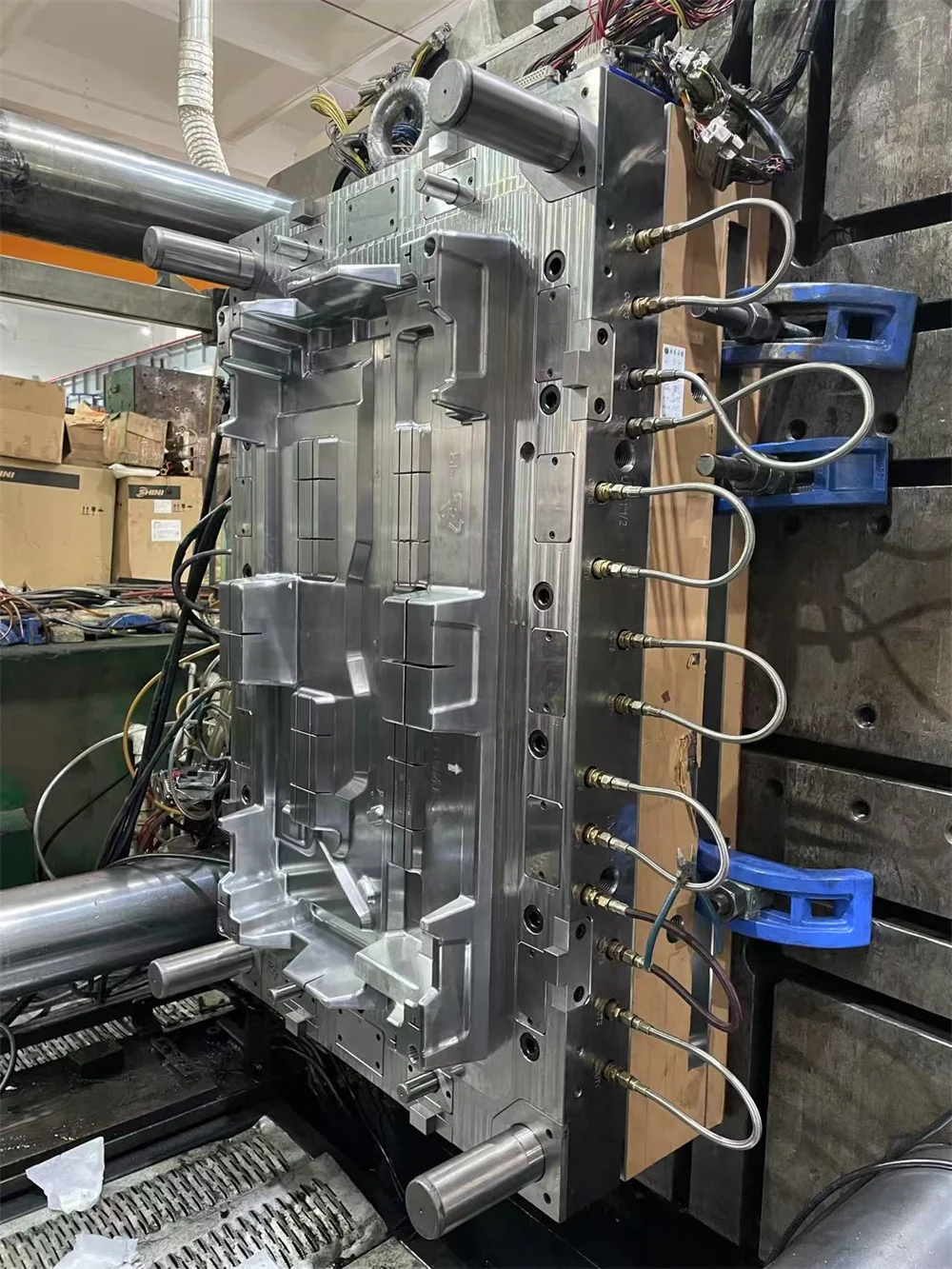

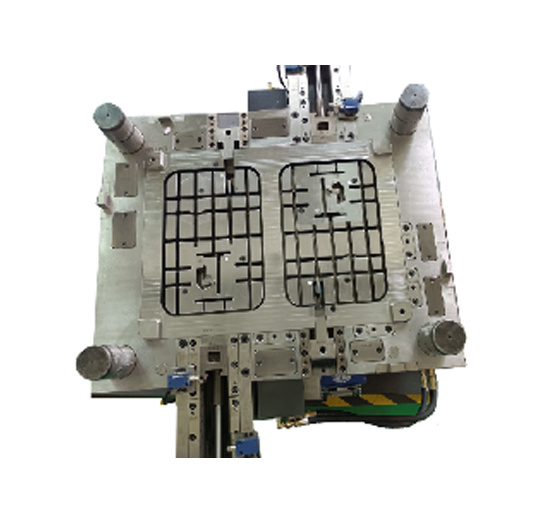

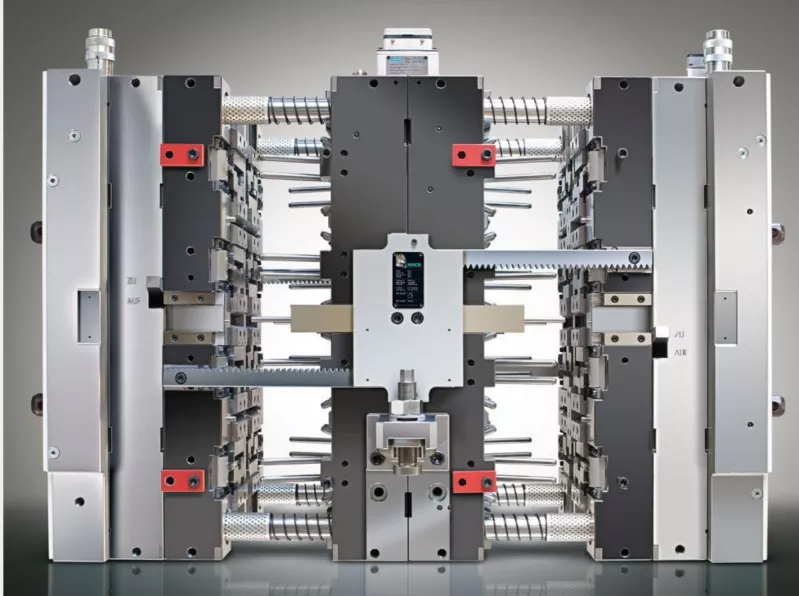

Automotive mold tools are precision-engineered devices used to shape plastic materials into specific forms during the injection molding process. For radiator components, the mold tools must accommodate the complexities of fluid dynamics and thermal expansion. As such, the design of these tools often includes intricate features that ensure the final product meets stringent performance standards.

One of the critical aspects of automotive mold tools is the choice of materials. Typically, high-grade steel or aluminum alloys are used due to their durability and ability to withstand the high pressures and temperatures involved in the injection molding process. The selected material must not only be robust but also have excellent thermal conductivity to ensure consistent cooling during molding. Moreover, the surface finish of the mold can significantly influence the quality of the final product, impacting factors such as aesthetics and functionality.

The manufacturing of automotive mold tools for plastic radiator parts generally involves several steps, including design, prototyping, and testing. Advanced computer-aided design (CAD) software is frequently utilized to create detailed models of the molds, allowing engineers to visualize and refine their designs before production. Additionally, rapid prototyping techniques, such as 3D printing, are increasingly being employed to create initial mold prototypes for testing and validation.

Another essential consideration is the impact of mold design on the production efficiency and cost-effectiveness. Well-designed mold tools can enhance cycle times and reduce waste, ultimately contributing to lower manufacturing costs. By optimizing the injection process and minimizing defects, manufacturers can achieve higher yields and increased profitability.

In conclusion, automotive mold tools for plastic radiator parts are indispensable in crafting high-quality components that are vital for vehicle performance. A comprehensive understanding of the materials, design principles, and manufacturing processes involved is essential for professionals in the automotive sector. By focusing on these areas, companies can improve their production capabilities and maintain competitive advantages in the ever-evolving automotive market.

Automotive mold tools are precision-engineered devices used to shape plastic materials into specific forms during the injection molding process. For radiator components, the mold tools must accommodate the complexities of fluid dynamics and thermal expansion. As such, the design of these tools often includes intricate features that ensure the final product meets stringent performance standards.

One of the critical aspects of automotive mold tools is the choice of materials. Typically, high-grade steel or aluminum alloys are used due to their durability and ability to withstand the high pressures and temperatures involved in the injection molding process. The selected material must not only be robust but also have excellent thermal conductivity to ensure consistent cooling during molding. Moreover, the surface finish of the mold can significantly influence the quality of the final product, impacting factors such as aesthetics and functionality.

The manufacturing of automotive mold tools for plastic radiator parts generally involves several steps, including design, prototyping, and testing. Advanced computer-aided design (CAD) software is frequently utilized to create detailed models of the molds, allowing engineers to visualize and refine their designs before production. Additionally, rapid prototyping techniques, such as 3D printing, are increasingly being employed to create initial mold prototypes for testing and validation.

Another essential consideration is the impact of mold design on the production efficiency and cost-effectiveness. Well-designed mold tools can enhance cycle times and reduce waste, ultimately contributing to lower manufacturing costs. By optimizing the injection process and minimizing defects, manufacturers can achieve higher yields and increased profitability.

In conclusion, automotive mold tools for plastic radiator parts are indispensable in crafting high-quality components that are vital for vehicle performance. A comprehensive understanding of the materials, design principles, and manufacturing processes involved is essential for professionals in the automotive sector. By focusing on these areas, companies can improve their production capabilities and maintain competitive advantages in the ever-evolving automotive market.

Related news