Understanding Injection Molds for Drain Trays: A Comprehensive Guide

Injection molding is a widely-used manufacturing process that allows for the efficient production of plastic components, including drain trays. These trays are crucial in various settings, including kitchens, bathrooms, and industrial environments, where effective drainage and sanitation are essential. Understanding the role of injection molds in creating these products can enhance the quality and

2025-10-10

Injection molding is a widely-used manufacturing process that allows for the efficient production of plastic components, including drain trays. These trays are crucial in various settings, including kitchens, bathrooms, and industrial environments, where effective drainage and sanitation are essential. Understanding the role of injection molds in creating these products can enhance the quality and performance of drain trays.

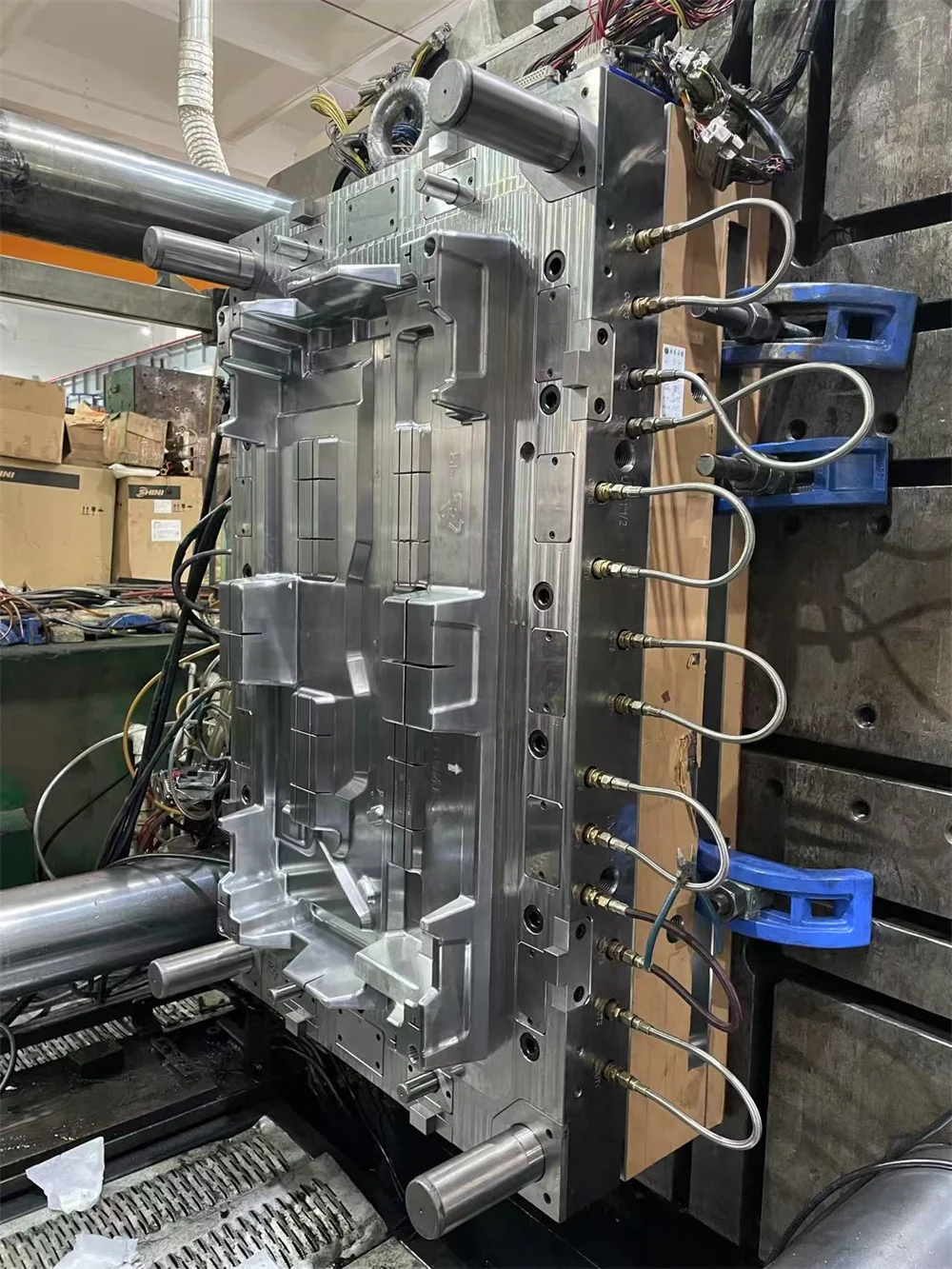

At its core, injection molding involves injecting molten plastic into a mold cavity, where it cools and solidifies into the desired shape. The design of the mold is critical, particularly for items like drain trays that require precise dimensions and drain hole configurations. A well-designed injection mold ensures that each tray produced is consistent in quality, which is vital for maintaining hygiene and efficiency in drainage.

The materials used in creating injection molds for drain trays can vary, but they are typically made from steel or aluminum. Steel molds are more durable and can withstand the rigors of high-volume production, while aluminum molds are lighter and easier to modify for lower production runs. The choice of material often depends on factors such as production volume, cost, and the complexity of the mold design.

One of the significant advantages of using injection molds for drain trays is the ability to produce complex shapes and features. For instance, drain trays may require specific angles, slopes, or even textured surfaces to enhance water drainage and prevent pooling. These design features can be easily incorporated into the mold, allowing for innovation in product design without significantly increasing manufacturing costs.

Another critical aspect to consider is the efficiency of the injection molding process. Once the mold is created, each cycle can produce multiple trays in a matter of seconds, significantly reducing lead times compared to other manufacturing methods. This efficiency makes injection molding a preferred choice for large-scale production, ensuring that suppliers can meet demand promptly.

Moreover, the use of injection molds for drain trays allows for material consistency and reduced waste. Because the process is highly controlled, manufacturers can minimize excess material and ensure that each tray meets the required specifications. This not only benefits the manufacturer but also contributes to sustainability efforts within the industry.

In conclusion, injection molds play a vital role in the production of drain trays, offering precision, efficiency, and the flexibility to create customized products. As industries continue to demand high-quality, durable, and innovative drainage solutions, understanding the intricacies of injection molding becomes increasingly important. By investing in quality mold design and production processes, manufacturers can ensure that their drain trays effectively meet the needs of various applications while maintaining high standards of performance and reliability.

At its core, injection molding involves injecting molten plastic into a mold cavity, where it cools and solidifies into the desired shape. The design of the mold is critical, particularly for items like drain trays that require precise dimensions and drain hole configurations. A well-designed injection mold ensures that each tray produced is consistent in quality, which is vital for maintaining hygiene and efficiency in drainage.

The materials used in creating injection molds for drain trays can vary, but they are typically made from steel or aluminum. Steel molds are more durable and can withstand the rigors of high-volume production, while aluminum molds are lighter and easier to modify for lower production runs. The choice of material often depends on factors such as production volume, cost, and the complexity of the mold design.

One of the significant advantages of using injection molds for drain trays is the ability to produce complex shapes and features. For instance, drain trays may require specific angles, slopes, or even textured surfaces to enhance water drainage and prevent pooling. These design features can be easily incorporated into the mold, allowing for innovation in product design without significantly increasing manufacturing costs.

Another critical aspect to consider is the efficiency of the injection molding process. Once the mold is created, each cycle can produce multiple trays in a matter of seconds, significantly reducing lead times compared to other manufacturing methods. This efficiency makes injection molding a preferred choice for large-scale production, ensuring that suppliers can meet demand promptly.

Moreover, the use of injection molds for drain trays allows for material consistency and reduced waste. Because the process is highly controlled, manufacturers can minimize excess material and ensure that each tray meets the required specifications. This not only benefits the manufacturer but also contributes to sustainability efforts within the industry.

In conclusion, injection molds play a vital role in the production of drain trays, offering precision, efficiency, and the flexibility to create customized products. As industries continue to demand high-quality, durable, and innovative drainage solutions, understanding the intricacies of injection molding becomes increasingly important. By investing in quality mold design and production processes, manufacturers can ensure that their drain trays effectively meet the needs of various applications while maintaining high standards of performance and reliability.

Related news