Understanding Injection Molds for Air Intake Pipe Assembly: A Comprehensive Guide

Injection mold technology plays a pivotal role in the manufacturing of complex components, particularly in the automotive sector. One significant application is the production of air intake pipe assemblies, which are vital for optimizing engine performance and efficiency. Understanding the intricacies of injection molds for air intake pipe assembly is essential for manufacturers looking to improve

2025-10-02

Injection mold technology plays a pivotal role in the manufacturing of complex components, particularly in the automotive sector. One significant application is the production of air intake pipe assemblies, which are vital for optimizing engine performance and efficiency. Understanding the intricacies of injection molds for air intake pipe assembly is essential for manufacturers looking to improve production quality and reduce costs.

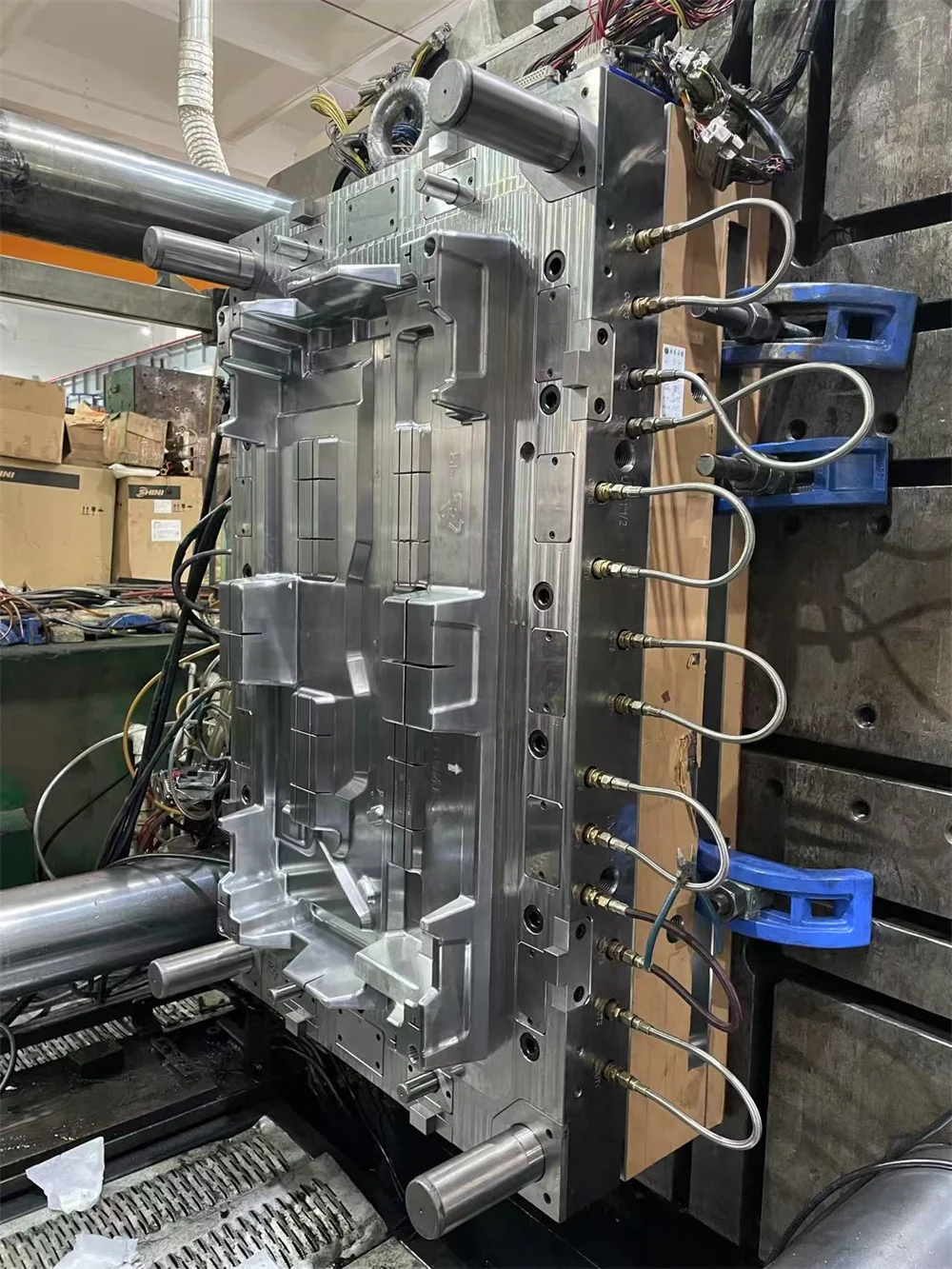

At its core, the process of injection molding involves injecting molten plastic into a mold cavity, where it cools and solidifies to form the final product. For air intake pipe assemblies, precision is critical. These components must not only meet stringent dimensional tolerances but also withstand various environmental conditions, making the choice of material and design crucial. Common materials used in the production of air intake pipes include polypropylene and nylon, known for their durability and resistance to heat and chemicals.

The design of an injection mold for an air intake pipe assembly typically incorporates features that enhance the flow characteristics of the air. This may include specific contouring and surface finishing that minimizes turbulence, thereby improving the overall performance of the engine. Advanced technologies such as computer-aided design (CAD) and simulations help in optimizing the mold design, ensuring that the end product achieves the desired performance metrics.

Moreover, the production of air intake pipe assemblies using injection molding offers several advantages over traditional manufacturing methods. These include higher production efficiency, reduced waste, and the ability to produce complex geometries that are often required for modern engines. Additionally, with the right mold design, manufacturers can achieve significant cost savings through reduced cycle times and lower material usage.

Quality control is another essential aspect of the injection molding process. Regular inspections and testing ensure that the air intake pipe assemblies meet industry standards and performance requirements. This includes monitoring for defects such as warping, dimensional inaccuracies, and material inconsistencies.

In conclusion, the injection mold for air intake pipe assembly is a vital component in the automotive manufacturing landscape. Understanding its design, materials, and production processes can significantly impact the quality and efficiency of the final product. As the automotive industry continues to evolve, the significance of advanced injection molding techniques will only increase, making it essential for manufacturers to stay abreast of the latest developments in this field. By investing in high-quality molds and utilizing cutting-edge technologies, businesses can enhance their production capabilities and maintain a competitive edge in the market.

At its core, the process of injection molding involves injecting molten plastic into a mold cavity, where it cools and solidifies to form the final product. For air intake pipe assemblies, precision is critical. These components must not only meet stringent dimensional tolerances but also withstand various environmental conditions, making the choice of material and design crucial. Common materials used in the production of air intake pipes include polypropylene and nylon, known for their durability and resistance to heat and chemicals.

The design of an injection mold for an air intake pipe assembly typically incorporates features that enhance the flow characteristics of the air. This may include specific contouring and surface finishing that minimizes turbulence, thereby improving the overall performance of the engine. Advanced technologies such as computer-aided design (CAD) and simulations help in optimizing the mold design, ensuring that the end product achieves the desired performance metrics.

Moreover, the production of air intake pipe assemblies using injection molding offers several advantages over traditional manufacturing methods. These include higher production efficiency, reduced waste, and the ability to produce complex geometries that are often required for modern engines. Additionally, with the right mold design, manufacturers can achieve significant cost savings through reduced cycle times and lower material usage.

Quality control is another essential aspect of the injection molding process. Regular inspections and testing ensure that the air intake pipe assemblies meet industry standards and performance requirements. This includes monitoring for defects such as warping, dimensional inaccuracies, and material inconsistencies.

In conclusion, the injection mold for air intake pipe assembly is a vital component in the automotive manufacturing landscape. Understanding its design, materials, and production processes can significantly impact the quality and efficiency of the final product. As the automotive industry continues to evolve, the significance of advanced injection molding techniques will only increase, making it essential for manufacturers to stay abreast of the latest developments in this field. By investing in high-quality molds and utilizing cutting-edge technologies, businesses can enhance their production capabilities and maintain a competitive edge in the market.

Related news