IML Plastic Injection Parts: Revolutionizing Consumer Products with Innovative Solutions

IML Plastic Injection Parts: Revolutionizing Consumer Products with Innovative Solutions Table of Contents 1. Understanding IML Technology in Plastic Injection Molding 2. The Advantages of Using IML Plastic Injection Parts 3. Applications of IML in Consumer Products 4. IML vs. Traditional Labeling Methods: A Comparative Analysis 5. Future Trends in IML Technology 6. The Manufacturing P

2025-10-06

IML Plastic Injection Parts: Revolutionizing Consumer Products with Innovative Solutions

Table of Contents

1. Understanding IML Technology in Plastic Injection Molding

2. The Advantages of Using IML Plastic Injection Parts

3. Applications of IML in Consumer Products

4. IML vs. Traditional Labeling Methods: A Comparative Analysis

5. Future Trends in IML Technology

6. The Manufacturing Process of IML Plastic Injection Parts

7. Sustainability in IML Plastic Injection Molding

8. Frequently Asked Questions About IML Plastic Injection Parts

9. Conclusion: The Future of Consumer Products with IML Technology

Understanding IML Technology in Plastic Injection Molding

In-Mold Labeling (IML) is a transformative technology in the realm of plastic injection molding. This advanced method integrates the labeling process directly into the molding cycle, allowing for a seamless fusion of label and plastic part. The result is a durable, high-quality product that enhances both aesthetics and functionality. The IML process involves placing a pre-printed label into the mold before the injection of molten plastic. This innovative technique offers a permanent bond between the label and the plastic, eliminating the need for additional adhesives or secondary operations.

The Advantages of Using IML Plastic Injection Parts

IML plastic injection parts offer numerous advantages over traditional methods.

Enhanced Aesthetics

IML allows for intricate designs and vibrant colors that are permanently embedded in the product. This capability enhances the visual appeal of consumer goods, making them more attractive to potential buyers.

Increased Durability

The fusion of label and plastic ensures that the graphics remain intact even after prolonged use, reducing wear and tear that often occurs with sticker labels or surface prints.

Cost-Effectiveness

By integrating the labeling process into the manufacturing cycle, companies can reduce labor costs and minimize material waste. This efficiency translates into lower production costs and higher profit margins.

Improved Product Safety

IML offers a hygienic solution, as the labels are molded into the product, preventing the risk of label detachment, which can pose safety concerns, especially in food packaging.

Applications of IML in Consumer Products

IML technology is versatile, finding applications in various consumer product sectors.

Food and Beverage Packaging

In the food industry, IML is widely used for containers such as yogurt cups, salad bowls, and take-out containers. The technology ensures that the labeling is part of the container, providing an effective barrier against contamination.

Cosmetics and Personal Care Products

In the cosmetics sector, IML is used for packaging items like creams, lotions, and gels. The technology allows brands to create visually appealing and durable packaging, essential for standing out in a competitive market.

Household Products

Household item manufacturers utilize IML for products such as cleaning bottles and storage containers, where durability and aesthetic appeal are critical.

IML vs. Traditional Labeling Methods: A Comparative Analysis

While traditional labeling methods like pressure-sensitive labels and shrink sleeves have been the industry standard for many years, IML presents distinct advantages.

Durability and Performance

Traditional labels often suffer from peeling, fading, or damage due to environmental exposure. IML, conversely, ensures that the label is an integral part of the product, enhancing longevity.

Design Flexibility

IML allows for a wider range of design options, including full-wrap labels and intricate graphics that are difficult to achieve with traditional methods.

Environmental Impact

IML technology can significantly reduce the environmental footprint by minimizing waste and improving recyclability, compared to traditional labeling methods that may involve additional materials.

Future Trends in IML Technology

The future of IML technology looks promising, with several emerging trends.

Sustainability Initiatives

With increasing environmental concerns, manufacturers are focusing on developing bio-based IML materials and sustainable practices to reduce their carbon footprint.

Smart Packaging Solutions

The integration of technology into IML is paving the way for smart packaging solutions that can provide information about the product's freshness, usage instructions, and recycling capabilities.

Customization and Personalization

As consumer preferences shift towards personalized products, IML technology can accommodate small batch runs and customization, allowing brands to engage with their customers more effectively.

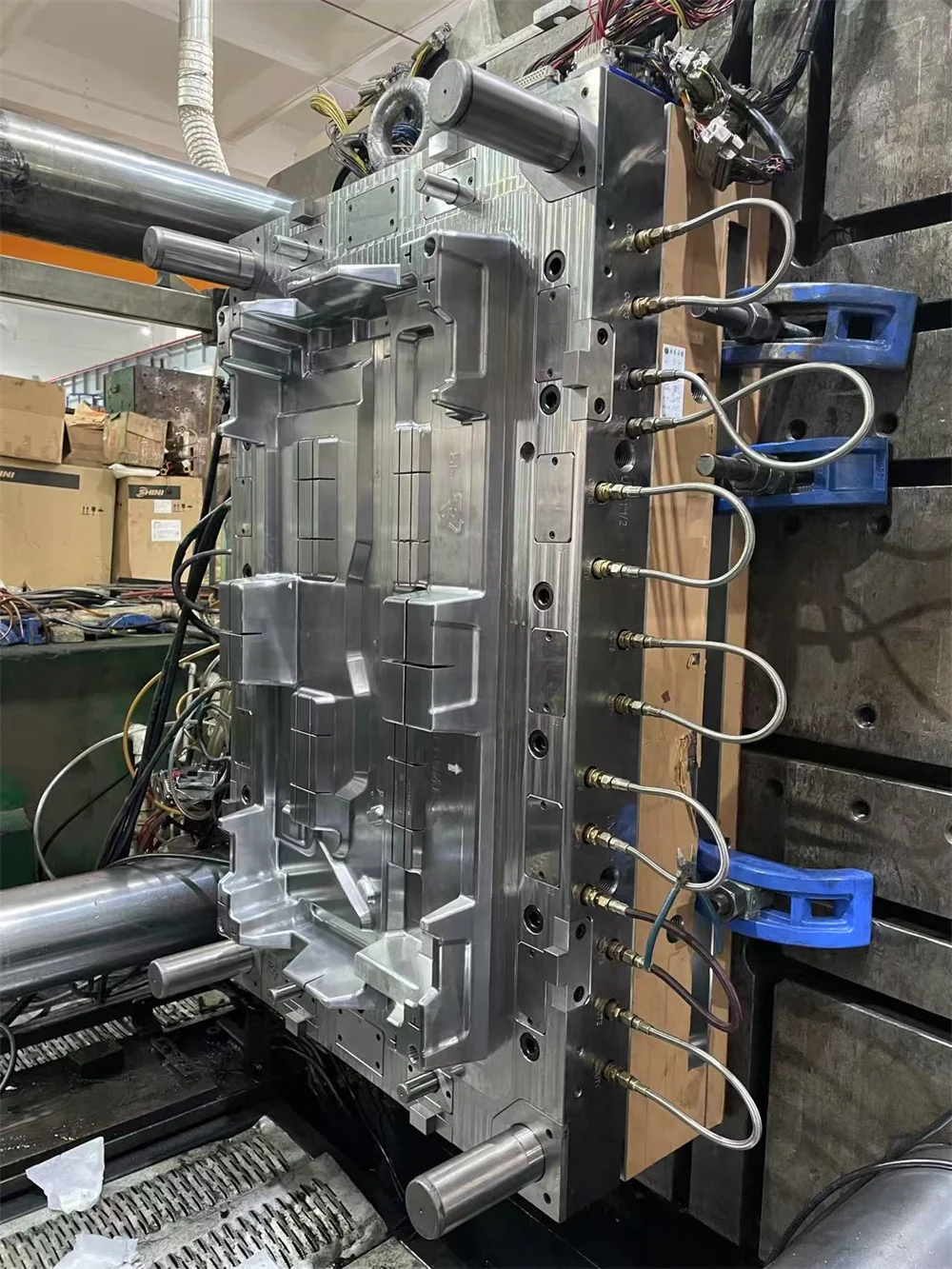

The Manufacturing Process of IML Plastic Injection Parts

The manufacturing process of IML plastic injection parts involves several critical steps.

Design and Preparation

The first step is designing the product and creating the mold, including the placement of the label within the mold.

Mold Setup

During setup, the pre-printed labels are placed into the mold, ensuring that they are correctly positioned for the injection process.

Injection Molding

Molten plastic is injected into the mold, enveloping the label and forming a strong bond as it cools.

Cooling and Ejection

Once the plastic has cooled sufficiently, the mold opens, and the finished product is ejected. Quality control checks are conducted to ensure that the labels are well-adhered and the product meets specifications.

Sustainability in IML Plastic Injection Molding

Sustainability is a growing concern within manufacturing, and IML technology is stepping up to meet environmental challenges.

Reduced Material Waste

IML production minimizes waste by combining labeling and molding processes, leading to efficient material use and reduced costs.

Recyclable Materials

Many IML solutions utilize recyclable materials, contributing to a circular economy. As consumer awareness of sustainability increases, IML plays a crucial role in creating eco-friendly packaging.

Energy Efficiency

The streamlined IML process can lead to energy savings as it reduces the steps involved in traditional labeling methods.

Frequently Asked Questions About IML Plastic Injection Parts

What is IML in plastic injection molding?

IML stands for In-Mold Labeling, a technique where labels are integrated into the plastic during the injection molding process, creating a durable and aesthetically pleasing product.

What are the benefits of using IML?

The benefits include enhanced durability, cost-effectiveness, improved aesthetics, and increased safety compared to traditional labeling methods.

Where is IML commonly used?

IML is commonly utilized in food packaging, cosmetics, and household products due to its ability to provide durable and visually appealing packaging.

How does IML compare to traditional labeling methods?

IML offers better durability, design flexibility, and sustainability compared to traditional methods, which often involve adhesive labels and additional materials.

What are the future trends in IML technology?

Future trends include a focus on sustainability, smart packaging solutions, and increasing customization options for brands.

Conclusion: The Future of Consumer Products with IML Technology

The adoption of **In-Mold Labeling (IML)** technology in plastic injection parts is revolutionizing the manufacturing landscape of consumer products. By enhancing durability, aesthetics, and sustainability, IML is poised to meet the evolving demands of consumers and manufacturers alike. As technology continues to advance, IML will likely play an even greater role in shaping the future of consumer products, providing innovative solutions that address both consumer preferences and environmental concerns. The potential for growth and transformation in this field is vast, making it an exciting time for businesses to explore the benefits of IML technology.

Related news