Stack Mold Applications: Optimizing Auto Component Manufacturing for Enhanced Efficiency

Stack Mold Applications: Optimizing Auto Component Manufacturing for Enhanced Efficiency Table of Contents 1. Introduction to Stack Mold Technology in Automotive Manufacturing 2. What is Stack Molding? 3. Benefits of Stack Molding in Auto Component Production 4. Key Applications of Stack Molding in the Automotive Sector 5. Design Considerations for Stack Molds 6. Material

2025-08-20

Stack Mold Applications: Optimizing Auto Component Manufacturing for Enhanced Efficiency

Table of Contents

- 1. Introduction to Stack Mold Technology in Automotive Manufacturing

- 2. What is Stack Molding?

- 3. Benefits of Stack Molding in Auto Component Production

- 4. Key Applications of Stack Molding in the Automotive Sector

- 5. Design Considerations for Stack Molds

- 6. Material Selection for Stack Molding

- 7. Future Trends in Stack Mold Technology

- 8. Frequently Asked Questions (FAQs)

- 9. Conclusion

1. Introduction to Stack Mold Technology in Automotive Manufacturing

The automotive industry is characterized by a relentless pursuit of efficiency, cost-effectiveness, and quality. In this competitive landscape, stack molding technology has emerged as a pivotal innovation in the manufacturing of auto components. By allowing multiple parts to be produced simultaneously, stack molds significantly enhance production capacity and reduce cycle times. This article explores the various applications and advantages of stack molding, shedding light on how this technology can optimize the manufacturing processes within the automotive sector.

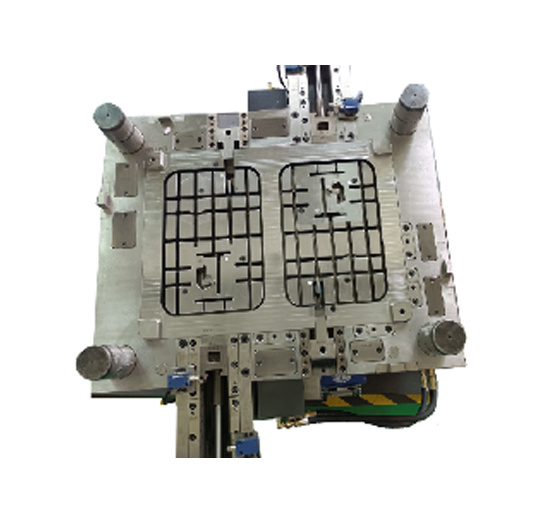

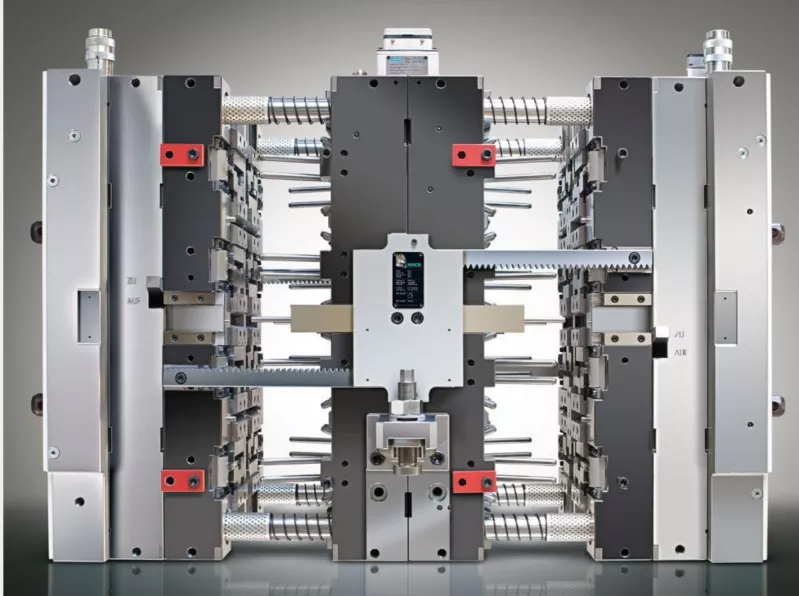

2. What is Stack Molding?

Stack molding, as a manufacturing technique, involves the use of a multi-layered mold to produce multiple parts in a single cycle. The design of stack molds typically includes two or more mold cavities arranged vertically or horizontally. This design allows for the simultaneous molding of several components, effectively doubling or tripling production outputs compared to traditional single-cavity molds. The process is particularly beneficial for producing complex geometries and intricate designs that are common in modern automotive components.

3. Benefits of Stack Molding in Auto Component Production

Stack molding offers numerous advantages that make it increasingly popular among automotive manufacturers:

3.1 Enhanced Production Efficiency

The primary benefit of stack molding is the ability to produce multiple components in a single cycle, which drastically reduces the time and resources required for production.

3.2 Cost-Effectiveness

By increasing output while minimizing cycle times, stack molding can significantly reduce manufacturing costs. This is particularly important in the competitive automotive market, where margins are tight.

3.3 Improved Quality and Precision

Stack molds are designed for precision, leading to improved dimensional accuracy and surface finish of the components produced. This quality is crucial for meeting the stringent standards of the automotive industry.

3.4 Flexibility in Design

Stack molding allows for versatile designs, enabling manufacturers to create complex parts that may be challenging to produce with traditional methods. This flexibility helps automotive companies innovate and meet evolving consumer demands.

4. Key Applications of Stack Molding in the Automotive Sector

Stack molding technology is utilized in various applications within the automotive industry, including:

4.1 Electrical Connectors

Electrical connectors are critical components in modern vehicles, and stack molding provides an efficient means of producing these intricate parts with high precision.

4.2 Interior Components

From dashboards to decorative trims, stack molds can create complex interior components that enhance both aesthetics and functionality.

4.3 Fluid Reservoirs

Stack molding is often used to manufacture fluid reservoirs, ensuring they meet the necessary design specifications while optimizing material usage.

4.4 Housing for Electronic Devices

As vehicles become increasingly reliant on technology, the demand for durable and efficient housings for electronic devices rises. Stack molding meets this demand effectively.

4.5 Structural Parts

Structural components that require strength and durability can also benefit from stack molding, making it a versatile choice for various applications.

5. Design Considerations for Stack Molds

When designing stack molds, several key considerations must be addressed to maximize efficiency and ensure quality:

5.1 Mold Geometry

The geometry of the mold affects the flow of material and the cooling process. Designers must optimize mold shape to ensure even material distribution and minimize defects.

5.2 Material Flow

Understanding how materials flow through the mold is crucial. Designers should account for factors such as viscosity and temperature to achieve optimal results.

5.4 Cooling Systems

Effective cooling systems are essential for maintaining production efficiency. Designers should ensure that cooling channels are appropriately placed to enhance the cooling rate.

6. Material Selection for Stack Molding

Choosing the right materials is critical for achieving the desired properties in stack-molded parts. Considerations include:

6.1 Thermoplastics

Thermoplastics are commonly used in stack molding due to their versatility and ease of processing. Materials like polypropylene and polycarbonate are popular choices.

6.2 Reinforced Materials

Reinforced materials, such as glass-fiber-reinforced plastics, offer enhanced strength and durability, making them suitable for structural components.

7. Future Trends in Stack Mold Technology

As the automotive industry evolves, so too does stack mold technology. Future trends to consider include:

7.1 Automation and Industry 4.0

The integration of automation and smart technologies is set to revolutionize stack molding, allowing for real-time monitoring and optimization of manufacturing processes.

7.2 Sustainable Practices

As sustainability becomes a priority, manufacturers are exploring eco-friendly materials and processes in stack molding to minimize environmental impact.

7.3 Advanced Simulation Techniques

Using advanced simulation software during the design phase can help manufacturers predict performance outcomes and troubleshoot potential issues before production begins.

8. Frequently Asked Questions (FAQs)

8.1 What industries can benefit from stack molding technology?

Stack molding is primarily used in the automotive industry but can also be beneficial for electronics, medical devices, and consumer products.

8.2 How does stack molding compare to traditional injection molding?

Stack molding offers higher efficiency and lower production costs by enabling the simultaneous production of multiple parts, whereas traditional injection molding typically focuses on single-part production.

8.3 What factors should be considered when designing stack molds?

Key factors include mold geometry, material flow, cooling systems, and the selection of appropriate materials to ensure quality and efficiency.

8.4 Can stack molding be used for complex designs?

Yes, stack molding is particularly advantageous for producing complex designs, allowing manufacturers to create intricate components that meet modern automotive needs.

8.5 What are the environmental considerations in stack molding?

Manufacturers are increasingly focusing on sustainable practices, such as using eco-friendly materials and optimizing production to minimize waste and energy consumption.

9. Conclusion

Stack mold technology represents a significant advancement in the manufacturing of automotive components, providing numerous benefits such as enhanced efficiency, cost-effectiveness, and improved quality. As the automotive industry continues to evolve, embracing innovations like stack molding will be crucial for companies aiming to stay competitive. By understanding the applications, design considerations, and future trends associated with stack molding, manufacturers can optimize their production processes and meet the demands of the modern market. Embracing this technology today will pave the way for a more innovative and efficient automotive industry tomorrow.

Related news