Understanding Two Component Injection Molding in Automotive Electronics

Two component injection molding is a sophisticated manufacturing process widely utilized in the automotive electronics industry, particularly for producing components that require different materials or colors to be seamlessly integrated into a single product. This innovative technique involves injecting two distinct materials into a mold, allowing for improved functionality, aesthetics, and cost

2025-07-27

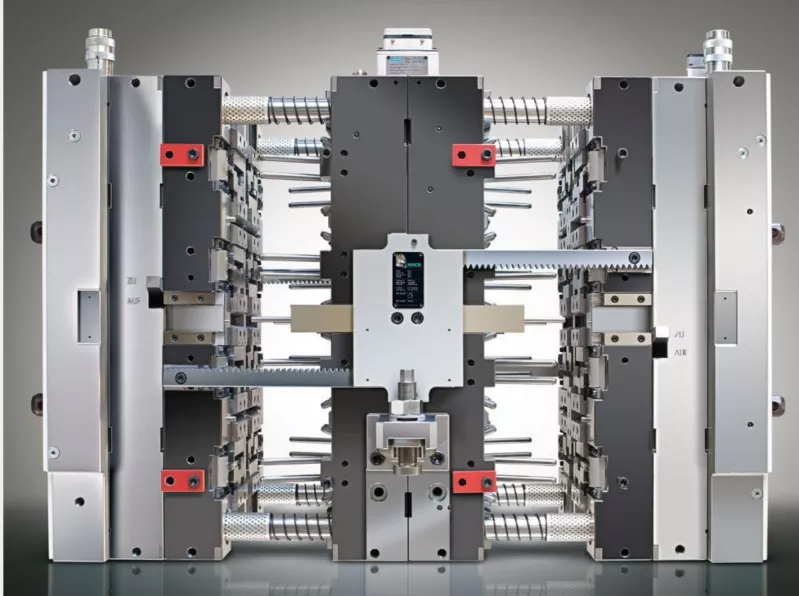

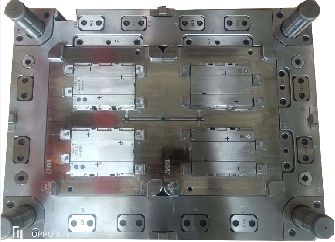

Two component injection molding is a sophisticated manufacturing process widely utilized in the automotive electronics industry, particularly for producing components that require different materials or colors to be seamlessly integrated into a single product. This innovative technique involves injecting two distinct materials into a mold, allowing for improved functionality, aesthetics, and cost efficiency in automotive electronic parts.

One of the primary advantages of two component injection molding is its ability to combine multiple functionalities into a single component. For instance, a component may require an outer layer that is resistant to heat or chemicals, while the inner layer provides structural integrity. This process enables manufacturers to create complex parts that might otherwise require assembly from multiple pieces, significantly reducing assembly time and potential points of failure.

Additionally, the use of two component injection molding allows for enhanced design flexibility. Engineers and designers can experiment with various material combinations to achieve specific mechanical properties, visual appeal, and even tactile experiences. This is particularly important in the automotive industry, where both the performance of electronic parts and the overall aesthetic of the vehicle play crucial roles in consumer satisfaction.

The process begins with a standard injection molding setup, where the first material is injected into the mold cavity. After the first material cools and solidifies, the mold is then adjusted to allow for the injection of the second material. This sequential process ensures that both materials bond effectively, resulting in a final product that exhibits the desired characteristics.

Moreover, two component injection molding can contribute to weight reduction in automotive design. By optimizing the material used in specific areas of a component, manufacturers can produce lighter parts without sacrificing strength or performance. This not only improves fuel efficiency but also enhances the overall driving experience.

In summary, two component injection molding is a vital process in the manufacturing of automotive electronics. Its ability to combine materials for improved performance and design makes it an essential technique in developing innovative automotive electronic parts. As the automotive industry continues to evolve with the advent of new technologies and consumer demands, mastering this manufacturing process will be crucial for companies looking to stay ahead in a competitive market. By leveraging the benefits of two component injection molding, manufacturers can produce high-quality, efficient, and stylish components that meet the diverse needs of modern automotive applications.

Related news