Understanding Auto Part Molding with Stack Molds: A Comprehensive Guide

Auto part molding is a crucial process in the automotive industry, especially for creating intricate components in vehicles, including electronic parts. Among the various molding techniques, stack molding stands out as a highly efficient method that can significantly enhance production capabilities. Stack molds utilize multiple layers of mold cavities, allowing manufacturers to produce several par

2025-07-18

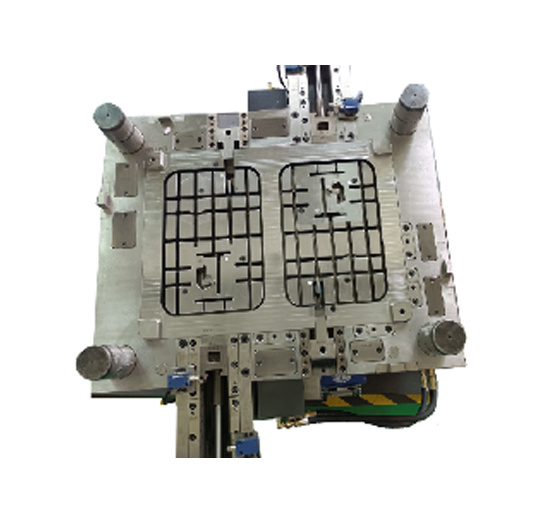

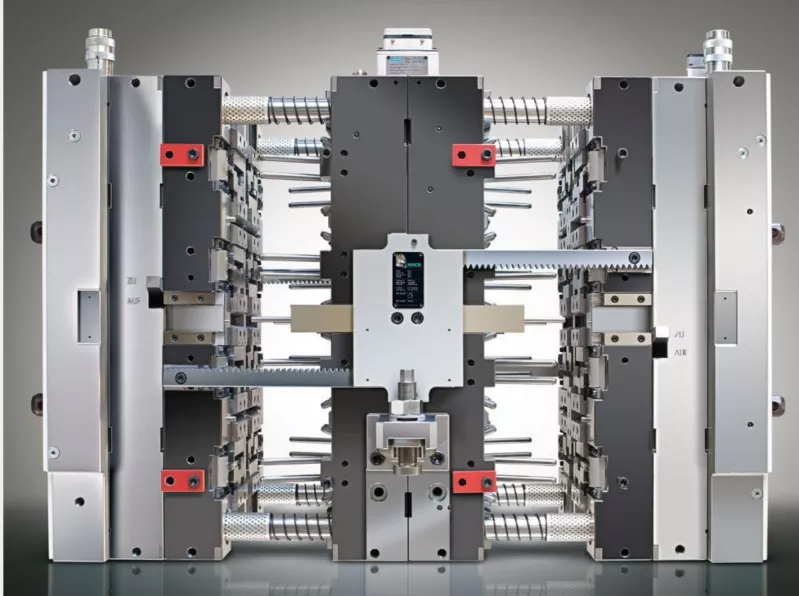

Auto part molding is a crucial process in the automotive industry, especially for creating intricate components in vehicles, including electronic parts. Among the various molding techniques, stack molding stands out as a highly efficient method that can significantly enhance production capabilities. Stack molds utilize multiple layers of mold cavities, allowing manufacturers to produce several parts simultaneously. This not only increases output but also optimizes the use of materials, making it a preferred choice in automotive applications.

One of the primary benefits of auto part molding with stack molds is its ability to reduce cycle times. Traditional molding methods often involve longer production times due to the need for separate molds for each part. In contrast, stack molding allows for simultaneous production, leading to faster turnaround times and increased productivity. This is particularly advantageous in the automotive sector, where demand for components can fluctuate rapidly due to market trends and consumer preferences.

In addition to improved efficiency, stack molding also offers enhanced precision and quality. The design of stack molds facilitates better control over the molding process, resulting in parts that are consistently manufactured to the desired specifications. This is vital for automotive electronics, where precision is paramount for functionality and safety. Components such as connectors, sensors, and other electronic assemblies often require intricate designs that stack molding can accommodate effectively.

Moreover, stack molding can help reduce material waste. By maximizing the number of parts produced in each cycle, manufacturers can minimize excess material usage. This not only contributes to cost savings but also aligns with the growing emphasis on sustainability within the automotive industry. Eco-friendly practices are becoming increasingly important, and efficient molding methods like stack molding play a significant role in reducing the overall environmental footprint of production processes.

Stack molds are versatile and can be tailored to accommodate various types of materials, including thermoplastics and thermosetting plastics, which are widely used in automotive electronics. The ability to mold different materials allows for the creation of components with varying properties, catering to the specific requirements of different applications within the vehicle.

In conclusion, auto part molding with stack molds is an advanced manufacturing technique that brings numerous advantages to the automotive electronics sector. Its ability to enhance efficiency, precision, and sustainability makes it an attractive option for manufacturers looking to optimize their production processes. As the industry continues to evolve, staying informed about innovative molding techniques will be essential for maintaining a competitive edge in the market.

One of the primary benefits of auto part molding with stack molds is its ability to reduce cycle times. Traditional molding methods often involve longer production times due to the need for separate molds for each part. In contrast, stack molding allows for simultaneous production, leading to faster turnaround times and increased productivity. This is particularly advantageous in the automotive sector, where demand for components can fluctuate rapidly due to market trends and consumer preferences.

In addition to improved efficiency, stack molding also offers enhanced precision and quality. The design of stack molds facilitates better control over the molding process, resulting in parts that are consistently manufactured to the desired specifications. This is vital for automotive electronics, where precision is paramount for functionality and safety. Components such as connectors, sensors, and other electronic assemblies often require intricate designs that stack molding can accommodate effectively.

Moreover, stack molding can help reduce material waste. By maximizing the number of parts produced in each cycle, manufacturers can minimize excess material usage. This not only contributes to cost savings but also aligns with the growing emphasis on sustainability within the automotive industry. Eco-friendly practices are becoming increasingly important, and efficient molding methods like stack molding play a significant role in reducing the overall environmental footprint of production processes.

Stack molds are versatile and can be tailored to accommodate various types of materials, including thermoplastics and thermosetting plastics, which are widely used in automotive electronics. The ability to mold different materials allows for the creation of components with varying properties, catering to the specific requirements of different applications within the vehicle.

In conclusion, auto part molding with stack molds is an advanced manufacturing technique that brings numerous advantages to the automotive electronics sector. Its ability to enhance efficiency, precision, and sustainability makes it an attractive option for manufacturers looking to optimize their production processes. As the industry continues to evolve, staying informed about innovative molding techniques will be essential for maintaining a competitive edge in the market.

Related news