The Essential Guide to Automotive Injection Mold Tooling: Key Insights for Industry Professionals

Automotive injection mold tooling plays a critical role in the manufacturing of various components within the automotive industry, particularly in the realm of electronic and electrical accessories. This process involves creating precise molds that shape raw materials into finished parts, ensuring high quality and efficiency in production. As the automotive market continues to evolve, understandin

2025-07-12

Automotive injection mold tooling plays a critical role in the manufacturing of various components within the automotive industry, particularly in the realm of electronic and electrical accessories. This process involves creating precise molds that shape raw materials into finished parts, ensuring high quality and efficiency in production. As the automotive market continues to evolve, understanding this technology is essential for staying competitive.

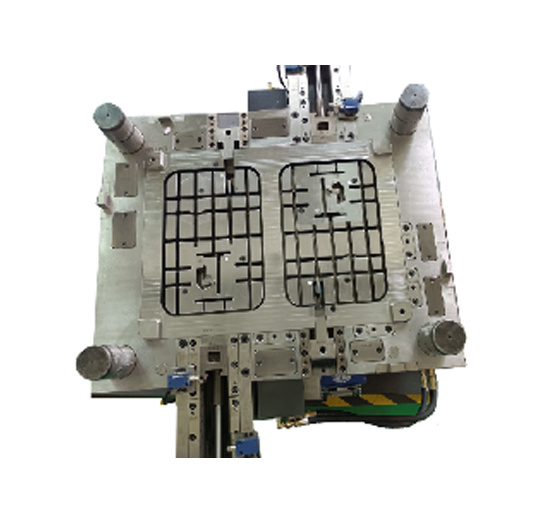

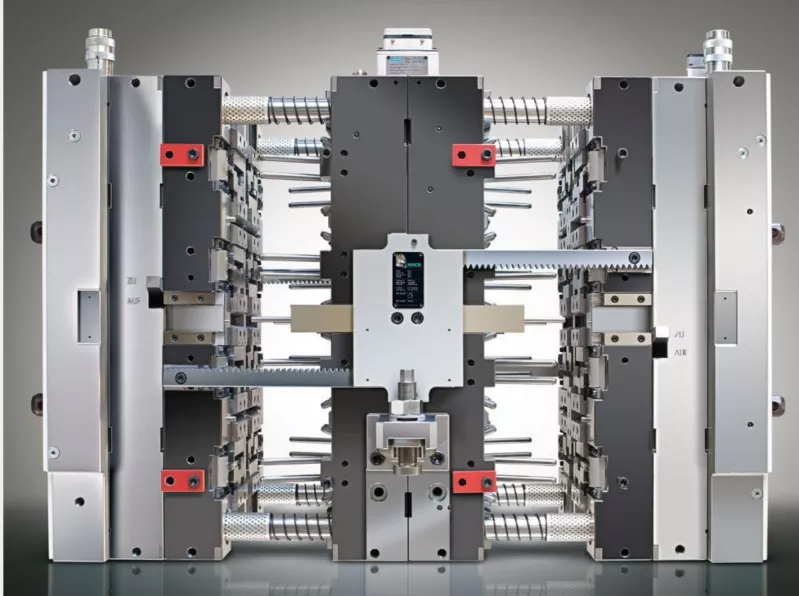

One of the primary benefits of effective automotive injection mold tooling is the ability to produce complex geometries with high precision. This capability is particularly important for automotive electronic components, which often require intricate designs to accommodate various functionalities. By utilizing advanced tooling techniques, manufacturers can reduce production times while maintaining stringent quality standards.

Another significant factor is the material selection process. In automotive applications, the choice of material directly impacts performance, durability, and cost-effectiveness. Common materials used in injection molding for automotive parts include thermoplastics and thermosetting plastics, each offering distinct properties suited for specific applications. Understanding the characteristics of these materials can aid manufacturers in making informed decisions that align with their production goals.

Furthermore, the design of the mold itself is crucial to the injection molding process. Designers must consider factors such as parting lines, draft angles, and cooling channels to ensure that the mold operates efficiently and produces high-quality parts. Effective mold design not only enhances product quality but also minimizes production costs by reducing material waste and cycle times.

Collaboration between design engineers and tooling specialists is vital in this process. By closely working together, teams can identify potential challenges early in the development phase, allowing for adjustments that can prevent costly delays later on. This collaborative approach fosters innovation and ensures that the final product meets the industry's stringent standards.

In conclusion, automotive injection mold tooling is a foundational aspect of manufacturing within the automotive electronics sector. By understanding the principles of mold design, material selection, and collaborative teamwork, industry professionals can enhance their production efficiency and product quality. As the automotive landscape continues to change, staying informed about these essential tools and techniques will be crucial for thriving in this competitive market. By embracing these insights, professionals can navigate the complexities of automotive injection mold tooling with confidence and precision.

One of the primary benefits of effective automotive injection mold tooling is the ability to produce complex geometries with high precision. This capability is particularly important for automotive electronic components, which often require intricate designs to accommodate various functionalities. By utilizing advanced tooling techniques, manufacturers can reduce production times while maintaining stringent quality standards.

Another significant factor is the material selection process. In automotive applications, the choice of material directly impacts performance, durability, and cost-effectiveness. Common materials used in injection molding for automotive parts include thermoplastics and thermosetting plastics, each offering distinct properties suited for specific applications. Understanding the characteristics of these materials can aid manufacturers in making informed decisions that align with their production goals.

Furthermore, the design of the mold itself is crucial to the injection molding process. Designers must consider factors such as parting lines, draft angles, and cooling channels to ensure that the mold operates efficiently and produces high-quality parts. Effective mold design not only enhances product quality but also minimizes production costs by reducing material waste and cycle times.

Collaboration between design engineers and tooling specialists is vital in this process. By closely working together, teams can identify potential challenges early in the development phase, allowing for adjustments that can prevent costly delays later on. This collaborative approach fosters innovation and ensures that the final product meets the industry's stringent standards.

In conclusion, automotive injection mold tooling is a foundational aspect of manufacturing within the automotive electronics sector. By understanding the principles of mold design, material selection, and collaborative teamwork, industry professionals can enhance their production efficiency and product quality. As the automotive landscape continues to change, staying informed about these essential tools and techniques will be crucial for thriving in this competitive market. By embracing these insights, professionals can navigate the complexities of automotive injection mold tooling with confidence and precision.

Related news