Unlocking Efficiency: The Advantages of Two Shot Auto Part Molding

Unlocking Efficiency: The Advantages of Two Shot Auto Part Molding The automotive industry is constantly evolving, driven by the need for enhanced efficiency, reduced costs, and superior product quality. One of the most innovative technologies making waves in this sector is **two-shot auto part molding**. This advanced manufacturing technique allows for the simultaneous processing of two different

2025-07-09

Unlocking Efficiency: The Advantages of Two Shot Auto Part Molding

The automotive industry is constantly evolving, driven by the need for enhanced efficiency, reduced costs, and superior product quality. One of the most innovative technologies making waves in this sector is **two-shot auto part molding**. This advanced manufacturing technique allows for the simultaneous processing of two different materials, resulting in high-quality components that meet the rigorous demands of modern vehicles. In this article, we will delve into the numerous advantages of two-shot molding, its applications in the automotive industry, and how it stands to redefine manufacturing processes.

Table of Contents

- What is Two Shot Molding?

- Benefits of Two Shot Molding in Automotive Manufacturing

- Enhanced Efficiency and Productivity

- Cost-Effectiveness of Two Shot Molding

- Design Freedom and Material Versatility

- Improved Product Quality and Consistency

- Reduced Waste and Environmental Impact

- Applications of Two Shot Molding in the Automotive Sector

- How Two Shot Molding Works

- Case Studies: Successful Implementations

- The Future of Two Shot Molding in Automotive Manufacturing

- Frequently Asked Questions

What is Two Shot Molding?

**Two shot molding** is an advanced manufacturing process that allows for the injection of two different materials, or two different colors of the same material, into a single mold. This process is particularly beneficial in creating complex components with multiple functionalities. In essence, two-shot molding combines two separate injection processes into one, streamlining production and enhancing the final product's features.

Benefits of Two Shot Molding in Automotive Manufacturing

Enhanced Efficiency and Productivity

One of the most significant advantages of **two-shot molding** is its ability to enhance efficiency. Traditional molding processes often require multiple steps and separate tooling for each material, which can slow down production. With two-shot molding, manufacturers can produce parts in a single cycle, drastically reducing lead times and minimizing the need for additional handling and assembly.

Cost-Effectiveness of Two Shot Molding

Implementing two-shot molding can lead to substantial cost savings for automotive manufacturers. The reduction in the number of processes not only shortens production time but also decreases labor costs associated with assembly and inspection. Furthermore, the ability to utilize different materials in a single part can eliminate the need for additional components, further streamlining costs.

Design Freedom and Material Versatility

Two-shot molding offers unparalleled design freedom. Engineers can combine materials with different properties, such as rigidity and flexibility, to create components that enhance performance. This versatility allows for innovative design solutions that can improve a vehicle's aesthetics and functionality. For instance, a single component might feature a hard outer layer for durability while having a softer inner material for grip or comfort.

Improved Product Quality and Consistency

Quality control is paramount in the automotive industry, and two-shot molding excels in this area. The precision of a single molding process minimizes the chances of defects that can occur with multi-part assembly. This results in components that not only meet but often exceed stringent quality standards, providing consumers with reliable and durable products.

Reduced Waste and Environmental Impact

In today's environmentally conscious market, reducing waste is more critical than ever. Two-shot molding contributes to sustainability by minimizing scrap material and reducing energy consumption. Since the process is more efficient, manufacturers can produce more parts with less energy and material, resulting in a lower carbon footprint and a more sustainable production model.

Applications of Two Shot Molding in the Automotive Sector

The applications of two-shot molding in the automotive industry are vast. From interior components to exterior parts, this technique is transforming how manufacturers approach production. Common applications include:

- **Dashboard components**: Combining hard plastics and soft-touch materials for enhanced comfort and aesthetics.

- **Grilles and lighting housings**: Utilizing different colors and materials to improve visibility and design.

- **Switches and controls**: Merging different tactile materials for improved user interaction.

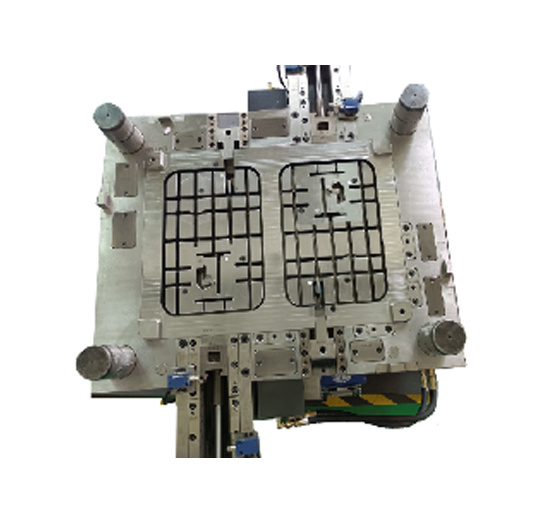

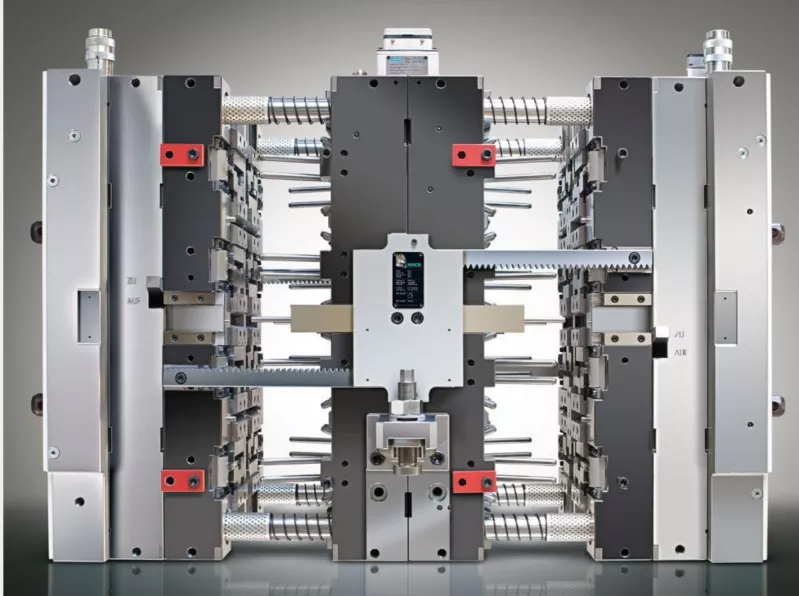

How Two Shot Molding Works

The **two-shot molding process** involves several key steps:

- Mold Preparation: A mold is created that can accommodate both materials. This mold usually contains two separate cavities designed to inject each material.

- First Injection: The first material is injected into the mold, forming the primary structure of the component.

- Curing and Cooling: The first material is allowed to cure and cool before the second injection.

- Second Injection: The second material is injected, bonding with the first to create a single, cohesive part.

- Final Product: Once fully cured, the finished part is ejected from the mold, ready for further processing or installation.

Case Studies: Successful Implementations

To understand the impact of two-shot molding on the automotive industry, consider the following case studies:

Case Study 1: Automotive Dashboard Production

A leading automotive manufacturer integrated two-shot molding into their dashboard production line, resulting in a 25% reduction in manufacturing time. The ability to create complex surfaces and textures in one shot improved both the aesthetic appeal and functionality of their dashboards.

Case Study 2: Lighting Components

Another company utilized two-shot molding for their lighting housings, which required both rigidity and transparency. By combining a rigid polycarbonate with a softer elastomer, they enhanced the durability and safety of their products while streamlining production and reducing costs.

The Future of Two Shot Molding in Automotive Manufacturing

The future of two-shot molding in the automotive industry looks bright. As manufacturers continue to seek ways to improve efficiency and reduce costs, the adoption of this technology is expected to grow. Innovations in materials science are also paving the way for even more applications, allowing for greater versatility and improved performance in auto parts. As the automotive sector embraces **sustainability** and innovation, two-shot molding will undoubtedly play a pivotal role in shaping its future.

Frequently Asked Questions

1. What materials can be used in two-shot molding?

Two-shot molding can accommodate a variety of materials, including thermoplastics, elastomers, and even some metals, depending on the application and desired properties of the final product.

2. How does two-shot molding compare to traditional molding methods?

Two-shot molding offers several advantages over traditional methods, such as reduced production time, lower labor costs, increased design flexibility, and improved overall product quality.

3. Is two-shot molding suitable for all types of automotive parts?

While two-shot molding is highly versatile, its suitability for a specific application depends on the part's design and functional requirements. It is particularly effective for components that benefit from combining different materials.

4. What are the typical lead times for two-shot molded parts?

Lead times can vary based on the complexity of the part and the specific materials used. However, two-shot molding generally reduces lead time compared to traditional multi-step processes.

5. Can two-shot molding help in reducing production waste?

Yes, two-shot molding significantly reduces scrap and waste by combining multiple processes into a single injection cycle, leading to a more efficient use of materials throughout the production process.

Conclusion

In the competitive landscape of the automotive industry, **two-shot auto part molding** emerges as a revolutionary technology that not only enhances manufacturing efficiency but also significantly contributes to cost reduction, product quality, and environmental sustainability. By embracing this innovative approach, automotive manufacturers can unlock new possibilities for product design and improve their overall operational effectiveness. As the automotive sector continues to evolve, two-shot molding is poised to become a cornerstone of modern manufacturing practices, driving both innovation and excellence in the industry.

Related news