Streamlining Production of Car Interiors with Stack Molding: Revolutionizing Automotive Manufacturing

Streamlining Production of Car Interiors with Stack Molding Introduction to Stack Molding in Automotive Manufacturing The automotive industry constantly seeks ways to improve both efficiency and quality in vehicle production. One such innovation is **stack molding**, a technique that optimizes the manufacturing process of car interiors. By leveraging this advanced method, manufacturers can signifi

2025-07-15

Streamlining Production of Car Interiors with Stack Molding

Introduction to Stack Molding in Automotive Manufacturing

The automotive industry constantly seeks ways to improve both efficiency and quality in vehicle production. One such innovation is **stack molding**, a technique that optimizes the manufacturing process of car interiors. By leveraging this advanced method, manufacturers can significantly reduce lead times and increase the durability of automotive components. In this article, we will explore how stack molding is revolutionizing car interior production and its implications for the future of automotive manufacturing.

Understanding Stack Molding: A Comprehensive Overview

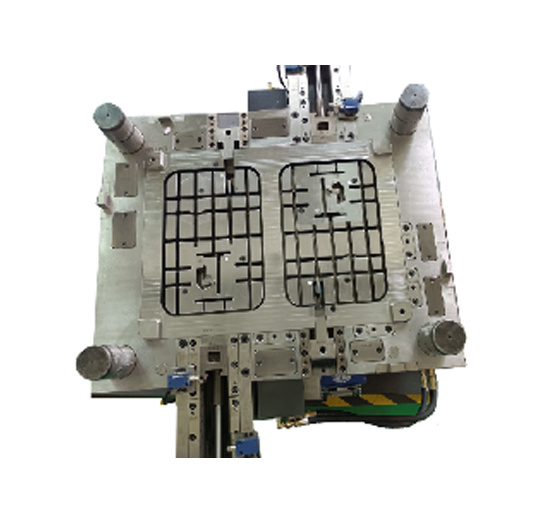

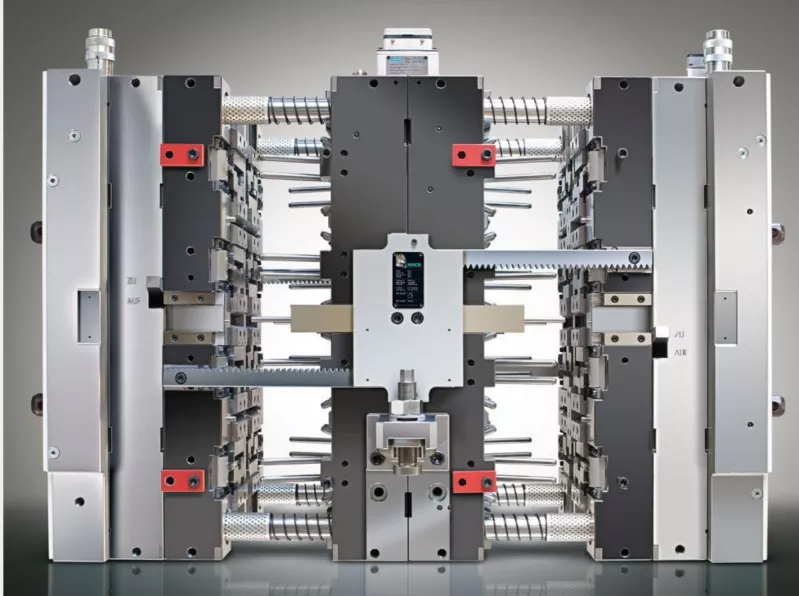

Stack molding involves the use of multiple cavities stacked on top of each other within a single mold. This technique allows for the simultaneous production of multiple parts, thus maximizing production efficiency.

The Importance of Stack Molding in Auto Manufacturing

1. **Increased Production Speed**: By producing multiple parts in a single cycle, stack molding dramatically reduces cycle times.

2. **Cost Efficiency**: The reduction in cycle times results in lower operational costs and higher output, making it an attractive option for manufacturers.

3. **Enhanced Quality Control**: The simultaneous molding of parts can lead to more consistent quality across components.

Key Advantages of Stack Molding for Car Interiors

1. Space Efficiency

Stack molding design allows manufacturers to utilize mold space more effectively, requiring less floor space in production facilities. This efficiency is crucial in an industry where space is a premium.

2. Material Optimization

This process typically uses materials more efficiently, reducing waste and contributing to more sustainable manufacturing practices.

3. Improved Aesthetic Quality

The ability to mold intricate designs and features means that car interiors can be produced with high aesthetic standards, appealing to consumer demands for quality.

4. Versatility in Material Use

Manufacturers can utilize various materials, including thermoplastics and thermosetting plastics, to achieve desired performance and aesthetic characteristics, expanding design possibilities for car interiors.

The Stack Molding Process Explained

1. Mold Design

The foundation of stack molding lies in the design of the mold. Designers must create a mold that accommodates multiple parts while ensuring ease of operation and maintenance.

2. Material Selection

Choosing the right materials is crucial. Factors such as durability, flexibility, and finish are considered to meet automotive requirements.

3. Injection Process

The injection process involves filling the mold cavities with material under high pressure, ensuring that the components take shape accurately.

4. Cooling and Ejection

Following injection, the mold is cooled, allowing the parts to solidify before being ejected. This step is vital for ensuring the integrity of each component.

Challenges in Implementing Stack Molding

Despite its advantages, stack molding presents challenges that manufacturers must navigate.

1. Initial Setup Costs

The investment in stack molding technology and mold design can be substantial. However, the long-term savings often justify this initial expenditure.

2. Technical Expertise Requirement

Skilled technicians are needed to operate and maintain stack molding equipment, which may require training and development for existing staff.

3. Quality Control Measures

While stack molding enhances efficiency, it is essential to implement rigorous quality control measures to ensure that all components meet stringent automotive standards.

Real-World Applications of Stack Molding in Car Interiors

1. Dashboard Production

Stack molding is widely used in producing complex dashboard components, integrating multiple functionalities into a single assembly.

2. Door Panels

Manufacturers leverage this technique to create aesthetically pleasing and durable door panels that enhance the overall vehicle experience.

3. Trim and Finish Components

Intricate designs in trim elements can be achieved, providing vehicles with a premium feel while maintaining production efficiency.

Future Trends in Stack Molding for Automotive Interiors

1. Advancements in Material Technology

As new materials emerge, stack molding processes will evolve, allowing for even more innovative designs and functionalities in car interiors.

2. Increased Automation

The integration of automation and robotics in stack molding processes is expected to further enhance production efficiency and reduce labor costs.

3. Sustainability Focus

With a growing emphasis on sustainability, manufacturers will increasingly explore eco-friendly materials and processes, aligning with consumer demands for greener products.

Conclusion: The Future of Automotive Interior Production

In conclusion, stack molding is not just a manufacturing technique; it represents a paradigm shift in how automotive interiors are produced. With its ability to enhance efficiency, reduce costs, and improve quality, stack molding is set to play a pivotal role in the future of automotive manufacturing. As we embrace advancements in technology and materials, the potential for innovation in car interiors will only continue to grow, making this an exciting time for manufacturers and consumers alike.

FAQs About Stack Molding in Automotive Manufacturing

1. What is stack molding?

Stack molding is a manufacturing technique that allows for the production of multiple parts in a single mold by stacking cavities vertically.

2. How does stack molding improve production efficiency?

By allowing manufacturers to produce several parts simultaneously, stack molding significantly decreases cycle times and increases output.

3. What materials are commonly used in stack molding?

Common materials include thermoplastics and thermosetting plastics, which are chosen based on the desired characteristics of the final product.

4. What are the challenges of implementing stack molding?

Challenges include high initial setup costs, the need for skilled technicians, and ensuring thorough quality control.

5. What is the future of stack molding in the automotive industry?

Future trends include advancements in material technology, increased automation, and a focus on sustainability, further enhancing the appeal of stack molding in automotive production.

Related news