plastic injection parts Injection Molding Service for mobile case

subcategory:

Key Word:

IML plastic injection part

Shaping mode: Plastic Injection Mould Place of origin: Guangdong, China Model number: Customized Product material: Plastic Color: Depend on you Size: Customized Product material available: ABS/PS/PC/PP/PVC/PBT/PE/PMMA Mold life: 200,000-500,000 Shots Drawing format: TEP/DWG/PRT/SAT/IGES/SLDASM/SLDPRT/CATPart Format Etc Mold lead time: 30-40days Mold tolerance: 0.02mm Product lead time: 3-5 days Product tolerance: ±0.05mm Product MOQ: 1 Piece available as sample Runner: Hot runner\ Cold runner

- Detail Info

-

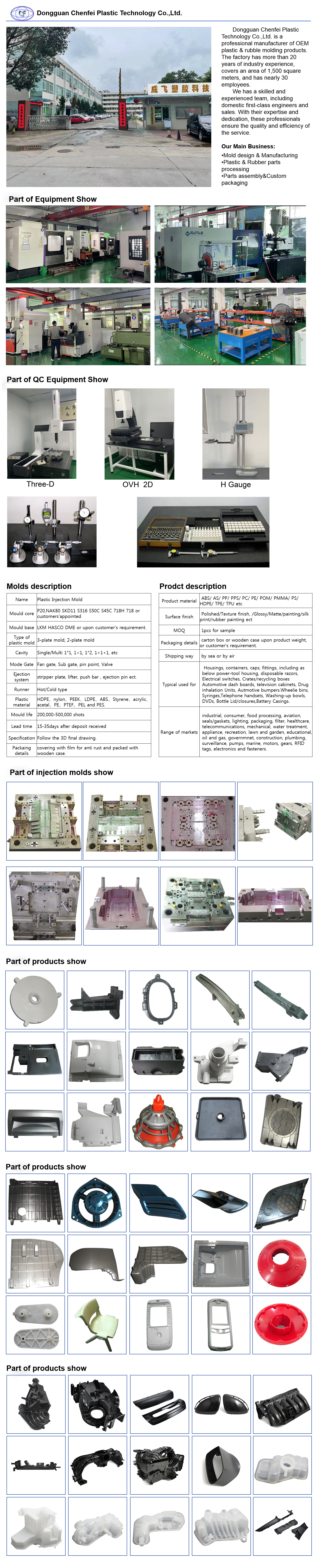

Auto injection molds for plastic parts are essential tools in modern automotive manufacturing, playing a pivotal role in producing high-precision, durable plastic components that meet the industry’s strict performance and safety demands.

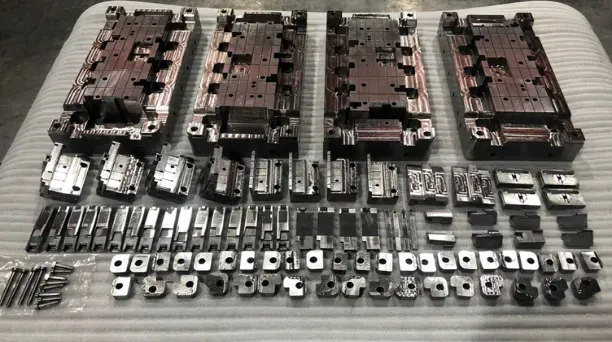

A key factor in the performance of auto injection molds lies in their material composition. High-strength tool steels—such as DIN 2344 (for high-temperature resistance), DIN 2738 (for corrosion protection), and STAVAX (for high-gloss surface finishes)—are widely used to construct mold cores and cavities. These materials offer hardness levels between 45-58 HRC, enabling the molds to withstand repeated injection cycles (typically 500,000 to 1.2 million cycles) without dimensional deformation. Additionally, advanced surface treatments like PVD coating or nitriding further enhance mold durability, reducing wear from abrasive thermoplastics such as PP (polypropylene), ABS (acrylonitrile butadiene styrene), and PA (polyamide)—the most common plastics for automotive parts.

Design innovation is another hallmark of auto injection molds for plastic parts. To meet the tight tolerances (often ±0.02mm) required for automotive components, molds integrate precision engineering features such as hot runner systems (to minimize material waste and ensure uniform plastic flow) and multi-cavity designs (to boost production efficiency by manufacturing multiple parts in a single cycle). For complex parts like dashboard housings or sensor enclosures, molds also incorporate slider or lifter mechanisms to accommodate undercuts, ensuring seamless demolding without damaging the plastic part. These design elements are tailored to the unique needs of automotive applications, where fit and function directly impact vehicle safety.

The application scope of auto injection molds covers a wide range of plastic automotive parts, spanning interior, exterior, and under-hood components. Interior parts include dashboard panels, door trim inserts, and seat belt housings—where molds must deliver consistent texture and color matching to align with automotive design standards. Exterior components such as bumper reinforcement brackets, headlight bezels, and grille inserts rely on molds that produce parts with high impact resistance and weather durability. Under-hood parts like fuel line connectors, sensor housings, and battery casings require molds compatible with heat-resistant plastics, as they operate in high-temperature environments.

Shipping Package

Video Display

Questions And Answers

Related Products