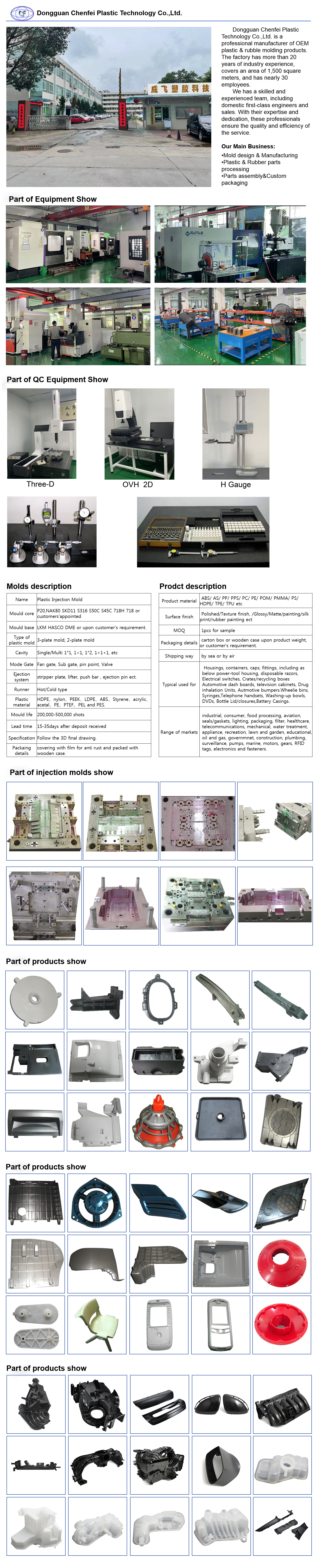

Custom Professional Cheap Plastic Injection Molding Service Product

subcategory:

Key Word:

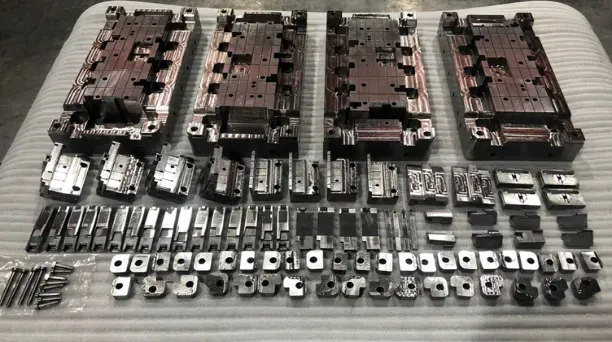

injection mold for Peugeot parts

Shaping mode: Plastic Injection Mould Place of origin: Guangdong, China Model number: Customized Product material: Plastic Color: Depend on you Size: Customized Product material available: ABS/PS/PC/PP/PVC/PBT/PE/PMMA Mold life: 200,000-500,000 Shots Drawing format: TEP/DWG/PRT/SAT/IGES/SLDASM/SLDPRT/CATPart Format Etc Mold lead time: 30-40days Mold tolerance: 0.02mm Product lead time: 3-5 days Product tolerance: ±0.05mm Product MOQ: 1 Piece available as sample Runner: Hot runner\ Cold runner

- Detail Info

-

Plastic injection molding is a highly efficient and versatile manufacturing process used to produce a wide range of plastic products. This process involves injecting molten plastic material into a mold cavity under high pressure, where it cools and solidifies to take the shape of the mold. The result is a precise, durable, and cost-effective solution for creating complex plastic components in large quantities.

One of the key advantages of plastic injection molding is its ability to produce high-precision parts with tight tolerances. This makes it ideal for industries that require intricate and reliable components, such as automotive, electronics, medical devices, and consumer goods. Here are some of the main benefits:

High Efficiency

Plastic injection molding allows for the production of large quantities of parts quickly. Once the mold is created, it can be used repeatedly to produce thousands or even millions of identical components with minimal additional cost. This makes it an ideal choice for mass production.

Cost-Effective Production

The initial cost of creating a mold can be high, but once it is made, the cost per unit decreases significantly with each additional part produced. This makes plastic injection molding an economical solution for high-volume manufacturing.

Versatility in Material Choices

A wide variety of plastic materials can be used in the injection molding process, from standard thermoplastics to specialized engineering resins. This gives manufacturers the flexibility to choose the material that best suits their product’s requirements, whether it is for strength, flexibility, or resistance to heat or chemicals.

Complex Part Designs

Plastic injection molding is capable of producing parts with complex geometries that would be difficult or expensive to create using other manufacturing methods. This includes features like undercuts, internal cavities, and thin walls, which are easily accommodated in the mold.

Consistent Quality

Because of the high precision involved, plastic injection molding ensures that each part produced is identical. This results in consistent quality and fewer defects, reducing the need for secondary operations like trimming or reworking.

Fast Turnaround Time

Once the molds are created, parts can be produced in a matter of seconds to minutes per cycle, enabling manufacturers to meet tight deadlines and high-demand production schedules.

Applications of Plastic Injection Molding

Plastic injection molding is used in a variety of industries to create parts for a wide range of applications. Some common examples include:

Automotive Components

Parts such as bumpers, dashboards, and trim are commonly made using plastic injection molding due to its cost efficiency and ability to produce high-strength, lightweight components.

Electronics

Injection molded parts are used for enclosures, connectors, and internal components in products like smartphones, computers, and household appliances.

Medical Devices

Precision plastic components like syringes, surgical tools, and drug delivery systems are often made using this method to ensure high levels of accuracy and cleanliness.

Consumer Goods

Items like packaging, toys, kitchenware, and furniture are also made using plastic injection molding due to its versatility and cost efficiency.

Shipping Package

Video Display

Questions And Answers

Related Products