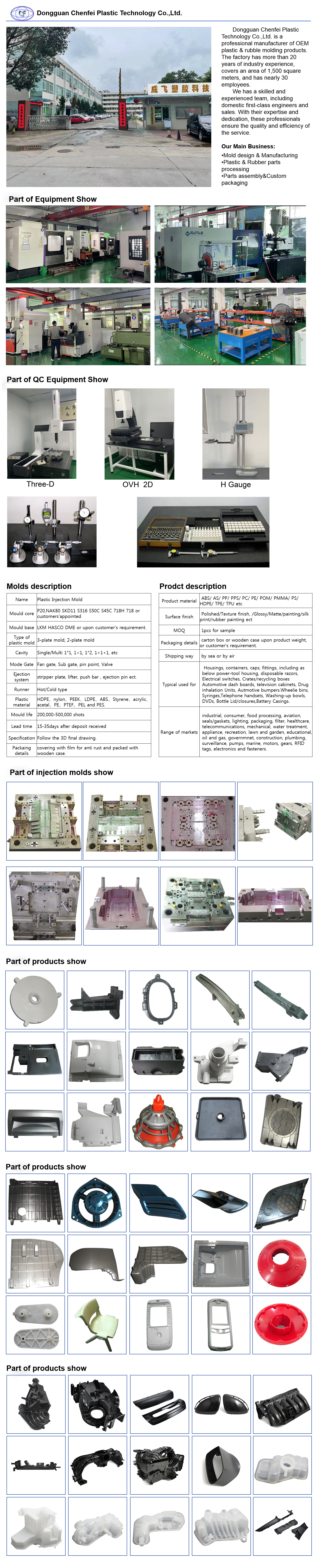

Plastic Injection parts OEM Custom Plastic Molding Service

subcategory:

Key Word:

IML plastic injection part

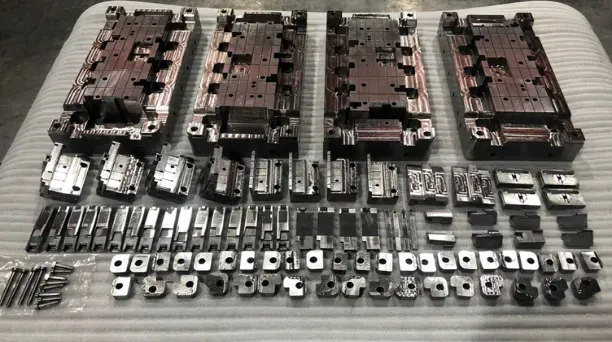

Shaping mode: Plastic Injection Mould Place of origin: Guangdong, China Model number: Customized Product material: Plastic Color: Depend on you Size: Customized Product material available: ABS/PS/PC/PP/PVC/PBT/PE/PMMA Mold life: 200,000-500,000 Shots Drawing format: TEP/DWG/PRT/SAT/IGES/SLDASM/SLDPRT/CATPart Format Etc Mold lead time: 30-40days Mold tolerance: 0.02mm Product lead time: 3-5 days Product tolerance: ±0.05mm Product MOQ: 1 Piece available as sample Runner: Hot runner\ Cold runner

- Detail Info

-

IML plastic injection parts are innovative components that combine In-Mold Labeling (IML) technology with precision plastic injection molding—two core technologies that redefine the performance and appearance of plastic products. Unlike traditional post-molding labeling, IML embeds decorative or functional labels directly into the plastic part during the injection process, creating a seamless bond between the label and the plastic substrate.

One of the standout features of IML plastic injection parts is their exceptional aesthetic flexibility. The IML process supports high-resolution printing, intricate patterns, and even textured finishes, allowing manufacturers to customize designs to match brand identities or consumer preferences. Whether for sleek home appliance panels), stylish cosmetic packaging, or durable automotive interior trims, these parts deliver a premium, high-end look that enhances product competitiveness. Moreover, the seamless surface of IML plastic injection parts simplifies cleaning, making them ideal for applications with hygiene requirements, such as medical device enclosures or food-contact containers.

Shipping Package

Video Display

Questions And Answers

Related Products