Injection tooling for Radiator tank,plastic radiator tank molding

subcategory:

Key Word:

plastic radiator tank molding

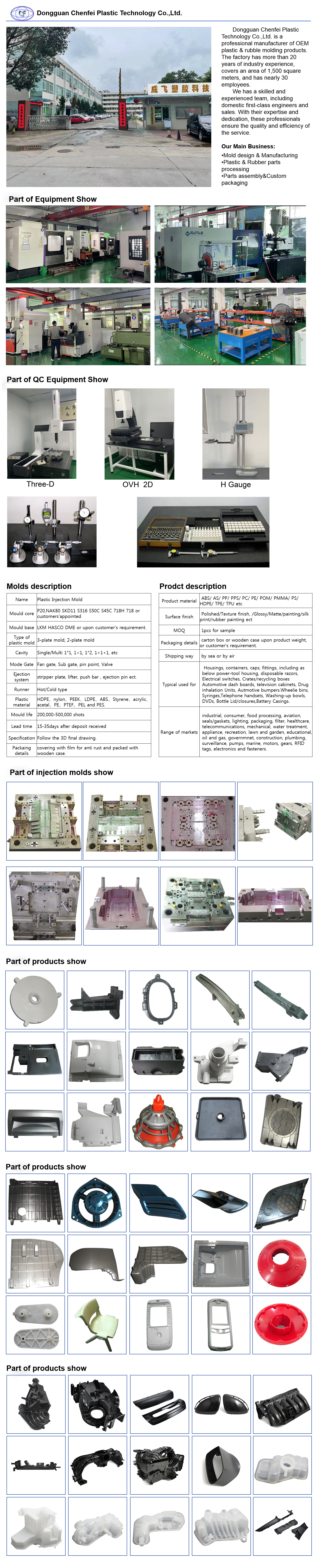

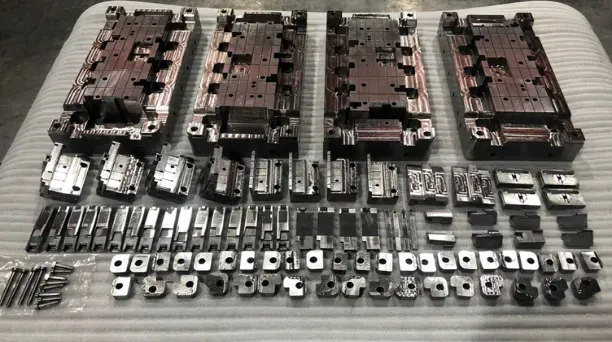

Shaping mode: Plastic Injection Mould Place of origin: Guangdong, China Model number: Customized Product material: Plastic Color: Depend on you Size: Customized Product material available: ABS/PS/PC/PP/PVC/PBT/PE/PMMA Mold life: 200,000-500,000 Shots Drawing format: TEP/DWG/PRT/SAT/IGES/SLDASM/SLDPRT/CATPart Format Etc Mold lead time: 30-40days Mold tolerance: 0.02mm Product lead time: 3-5 days Product tolerance: ±0.05mm Product MOQ: 1 Piece available as sample Runner: Hot runner\ Cold runner

- Detail Info

-

In the automotive and industrial cooling sectors, plastic radiator tank molding is making significant waves with its continuous advancements.Plastic radiator tank molding has become a crucial process in the production of radiator tanks. The use of plastic in this application offers several distinct advantages. Firstly, plastic is a lightweight material. In comparison to traditional metal radiator tanks, plastic ones can significantly reduce the overall weight of the radiator assembly. This weight reduction is of great importance in the automotive industry, as it can contribute to improved fuel efficiency and better vehicle performance.

The molding process for plastic radiator tanks has evolved to achieve high - precision results. Advanced molding techniques ensure that the tanks have a seamless and consistent shape. This is vital for the proper functioning of the radiator, as any irregularities in the tank's shape could lead to coolant leakage or inefficient cooling. Manufacturers are investing in state - of - the - art molding machinery and technologies to produce plastic radiator tanks with tight tolerances.

Another key aspect of plastic radiator tank molding is the ability to incorporate complex designs. With modern molding processes, it is possible to create radiator tanks with integrated features such as internal baffles, inlet and outlet ports in unique configurations, and enhanced structural supports. These design capabilities allow for better coolant flow management and overall improved heat dissipation.

In terms of cost - effectiveness, plastic radiator tank molding offers a competitive edge. The production of plastic tanks can be more cost - efficient compared to metal counterparts. The raw materials for plastic are often more readily available and less expensive, and the molding process can be optimized for mass production, reducing per - unit costs.

Furthermore, plastic radiator tanks are highly resistant to corrosion. Unlike metal tanks that may rust over time, plastic tanks can maintain their integrity in various operating conditions, including exposure to coolant chemicals and moisture. This corrosion resistance extends the lifespan of the radiator and reduces the need for frequent replacements.

The environmental aspect also cannot be ignored. Many plastic radiator tanks are made from recyclable materials, which aligns with the growing trend towards sustainable manufacturing. Recycling plastic radiator tanks at the end of their life cycle can reduce waste and contribute to a more circular economy.

As research and development in plastic molding continue, we can expect to see even more innovative features in plastic radiator tanks. From improved thermal conductivity to enhanced impact resistance, the future of plastic radiator tank molding looks promising, poised to revolutionize the way we think about radiator tank design and production in the cooling industry.

Shipping Package

Video Display

Questions And Answers

Related Products